To produce cement for various applications in an economic way, Lafarge modernised the production facilities at its plant in the town of Wössingen, Germany. The modernisation included the existing belt bucket elevator to the raw mill. The intralogistics specialist Beumer offered its innovative heavy-duty bucket elevators, permitting higher conveying capacity and longer service life. Thanks to this new technology, the existing bucket elevator could be easily altered.

The preheater tower of Lafarge Group’s cement plant looms just a few hundred metres before the sign Wössingen, near karlsruhe. in the seventies the plant has been taken over by the international producer of cement. Lafarge is market leader in many countries, such as France, England, Poland, Greece and Austria. in Germany, Lafarge is among the six leading producers. “Thanks to the state-of-the-art technology and a high sense of responsibility, we produce approximately 800 000 tonnes of cement per year for various applications and requirements at our Wössingen site“, says Stephan Schenk, head of Servicing & Development at Lafarge Zement Wössingen. Lafarge places particular value on production methods that are both energy-efficient and environmentally sound. For this reason, the systems have been modernised for more than EUr 60 million in 2008 and 2009. Now, the cement plant has a 5-stage heat exchanger and a new clinker cooler.

Production at Wössingen was changed from the Lepol process to the energy-saving dry process with heat exchanger and pre-calciner with no interruption to the operation. To make the production more cost-effective and environmentally sound, the company changed from the two-kiln operation to a single rotary kiln. Still, the kiln line now has a considerably higher capacity.

The system is fed with approximate 150 tonnes of raw material per hour. Accordingly, the complete production has changed. Due to the increase in performance and modernisation of the kiln line, the flow rate of the bucket elevator which transports limestone to the mill bunker for the raw mill had to be increased considerably.

High Wear of the Belt

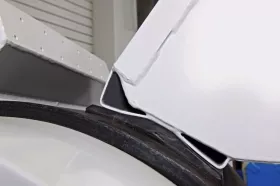

“Due to the higher flow rates we had to face more problems with the coarse-grained material“, remembers Schenk. Larger particles became repeatedly jammed between belt and bucket, causing substantial wear. Conventional belt bucket elevators are limited by the maximum grain size of the material to be conveyed as the conventional bucket mounting results in a gap of about 25 millimetres between bucket and belt. Larger particles may get stuck in this gap. This quickly results in belt damage when the belt runs around the return pulleys. The belt became porous already after two years, and a new solution needed to be found both to avoid belt cracks and to meet the growing requirements. Nevertheless, long-term thinking was called for, because a new belt is generally very expensive.

New heavy-duty Technology

At first, the engineers from the Wössingen plant wanted to replace the existing belt bucket elevator with a central chain bucket elevator. “We would have solved the problem with the transport of coarse-grained material“, Schenk says, “but a new central chain bucket elevator would have become quite expensive. “ In search of a suitable solution, the cement producer contacted some manufacturers of vertical conveyors – among others, the Beumer Group, headquartered in Beckum, Germany. The cooperation between Beumer

Group and the cement plant in Wössingen has a long tradition. When the engineers from Wössingen specified their conditions, Beumer recommended a newly developed technology. Central chain bucket elevators which transport limestone are subject to high wear as the raw material contains abrasive particles which act as sandpaper. Though identical with that of belt bucket elevators if used for materials that have little abrasive action, the service life of chain bucket elevators is much shorter in the case of strongly abrasive materials.

“The capacity is now 800 tonnes per hour“, enthuses Schenk. This is possible thanks to the new bucket geometry. There is no more gap between belt and bucket. Coarse-grained material do not jam during scooping and filling process.

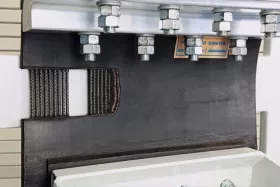

The buckets are mounted firmly to the back of the belt by segments and bolts. Belts with wire-free zones are used for the new heavy-duty bucket elevators just as with all Beumer belt bucket elevators. The buckets can be fastened to the belt without damaging the steel wires or even cutting them. The traction forces of the bucket elevator belt are maintained to full extend.

The new bucket shape also ensures smoother running and thus less noise. Depending on the material to be conveyed, the company offers buckets which are adapted to the material or mounts a dynamic bottom into the bucket elevator boot. This prevents wet and sticky material in the bucket elevator boot. And if explosive material is to be conveyed, all components are available in ATEX version.

Resisting high Loads

While developing the heavy-duty bucket elevator, the tensile strength of belts with wire-free zones was strengthened. The current belt has a tensile load of 2500 Newton per millimetre, the new belt with wire-free zones has a tensile load of 3300 Newton per millimetre.

The conveyor belts are more resistant against mechanical wear, and they are able to transport coarse-grained material and have high tensile load, all this makes the new heavy-duty bucket elevator the favourite conveying system for strongly abrasive material with high capacity and large centre distance.

According to Beumer, this belt has twice the service life of a chain. Bucket elevators fitted with this belt are a clear improvement over central chain bucket elevators when used for strongly abrasive material, such as clinker, ore or blast-furnace slag.

The timeline for the project was rather tight, just two months to plan and realise the modification. “We’ve got the ball rolling in October. The date of delivery was at the beginning of January and the bucket elevator was operated at the end of February“, Schenk says. Employees of Lafarge carried out the assembly under the watchful eye of the specialists from Beckum. It was less of an undertaking for the cement plant, because Beumer handled all the planning, whereas the employees at Wössingen only had to mount the buckets and the belt.

According to Schenk, this solution saved them a lot of money. The complete modification costs about EUR 80 000. In comparison, a new conventional belt would have cost EUR 60 000. If we assume that the Beumer solution lasts twice as long, the modification would amortise after a short period of time“, stresses Schenk. “Even after six months of operation there are no signs of wear. This was quite different with the old belt.“

■