Introduction

A subject of particular importance to the resources industries concerns the safe, intercontinental, bulk ship trans-ocean transport of large tonnages of bulk ores such as coal and mineral concentrates. It is most important that the stability of the loaded bulk cargo be guaranteed under all dynamic conditions due to the rolling and pitching motion of the vessel and the vibration influence emanating from the ship’s engines, propulsion equipment as well as whipping motion induced by waves.

While the reported incidences of cargo slip and movement leading to the capsizing and sinking of bulk carriers has significantly reduced in recent years, the problem of ensuring that stringent safety standards are met is a matter of paramount importance. This objective is strongly reinforced by the fact that transportation tonnages are increasing significantly and bulk ships are becoming much larger.

Currently, the safe ship transport of bulk cargoes is controlled, primarily, by the International Maritime Organisation (IMO) with reference to the “International Maritime Solid Bulk Cargoes (IMSBC) Code” [1]. This quite detailed publication includes test procedures, such as the tests for the determination of safe Transportable Moisture Limit (TML), which include the Flow Table Test, Penetration Test and Proctor/Fagerberg Test. In general, there appear to be elements of empiricism in these tests and there is no evidence of any reference to the now well established flow property tests that are an integral part of design and performance evaluation of industrial bulk solids handling plant. Furthermore, the wealth of knowledge that is now accumulated in the field of bulk solids handling has great potential for improving the knowledge and understanding of bulk cargo stability for safe transportation of bulk ores.

With this background, the purpose of this article is to briefly review the current practice adopted by the IMO and indicate areas where the recognised bulk solids test procedures may be applied, such as in the measurement of bulk strength, internal and boundary friction angles, bulk density variation with consolidation stress and moisture and fines migration under the influence of vibration. The main focus of the article will be on the stress states that exist in bulk solids stored in a ship’s hold and the generation of slip surfaces that could occur under the rolling and pitching action of the ship. The article is based on the original of work Roberts and Scott [2] of the University of Newcastle Australia and by Kirby [3] of the Warren Spring Laboratory.

1. International Maritime Organisation (IMO) Recommended Tests

Of particular importance with respect to vessel stability are bulk cargoes that may liquefy, generating slip planes that may cause the cargo to shift. This emphasises the need to establish the safe TML for bulk solids that are to be transported by ship. The IMSBC Code refers to the following three testing methods [1].

1.1 Flow Table Test

As stated by the IMSBC Code, this test “is generally suitable for mineral concentrates or other fine material with a maximum grain size of 1 mm [1]. It may also be used for other materials with a maximum grain size of 7 mm. It will not be suitable for materials coarser than this and may also not give satisfactory results for some materials with a high clay content. If the flow table test is not suitable for the material in question, the procedures adopted should be those approved by the authority of the port state”.

The test provides for the determination of the

- the Flow Moisture Point (FMP) of the material under impact or cyclical forces of the flow table apparatus,

- moisture content of the cargo, and

- the Transportable Moisture Limit (TML) of the test material.

1.2 Penetration Test

As stated by the IMSBC Code, this test “constitutes a procedure whereby a material in a cylindrical vessel is vibrated [1]. The flow moisture point is determined on the basis of the penetration depth of an indicator”.

The following relevant information is also given:

- The test is generally suitable for mineral concentrates, similar materials, and coals up to a top size of 25 mm.

- The sample, in a cylindrical vessel, is subjected to vertical vibration of 2 g rms ± 10% for 6 minutes.

- When the penetration depth of a bit put on the surface exceeds 50 mm, it is judged that the sample contains a moisture content greater than the flow moisture point.

1.3 Proctor/Fagerberg Test

The Proctor Fagerberg test has its origin derived from soil mechanics, with Proctor developing a method for control of the compaction of cores of earth dams and road sub-bases [4]. In this work it was shown that the dry density of a soil at a given compactive effort depends on the amount of water contained in the soil. The method applies a standard amount of energy via a falling weight hammer to moist soil placed in three layers (for the standard Proctor test) in a mould of standard dimensions.

As stated by the IMSBC Code, the scope of this test includes:

- Test method for both fine and relatively coarse-grained ore concentrates or similar materials up to a top size of 5 mm. This method must not be used for coal or other porous materials.

- Before the Proctor/Fagerberg test is applied to coarser materials with a top size greater than 5 mm, an extensive investigation for adoption and improvement is required.

- The TML of a cargo is taken as equal to the critical moisture content at 70% degree of saturation according to the Proctor/Fagerberg method test.

1.4 Method Comparison

When comparing test results obtained for the same bulk material cargo using the three IMO testing methods, a noticeable difference in the results is often observed, which may create some doubt over the validity of the testing methods and how applicable they are for a given bulk material.

2. Relevant Test for Determination of Bulk Solids Flow Properties

The apparent empirical nature of the foregoing IMO tests makes it difficult to see how they relate to the actual physical conditions applying in a bulk ship. On the other hand, in the field of bulk solids handling, the test procedures and design methodologies are closely related and well proven. The possible application of these procedures to bulk cargo transportation need to be explored. The relevant tests are briefly reviewed.

2.1 Flow Properties Tests

Focusing specifically on bin, hopper, stockpile, feeders, transfers and conveyors design, the laboratory tests aim to duplicate field conditions and provide the designer with such parameters as:

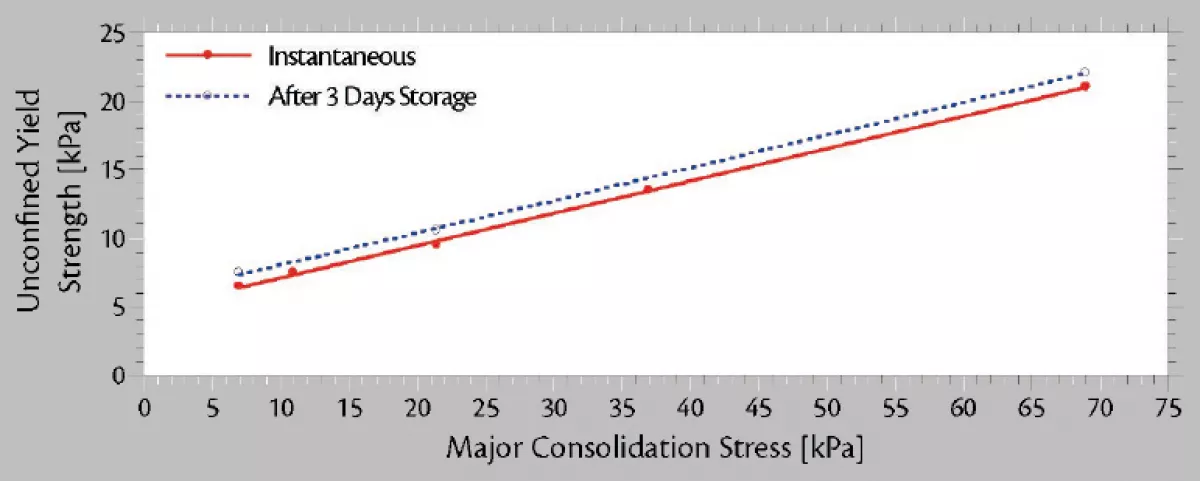

- Yield loci and flow functions for instantaneous and time storage conditions for the range of moisture contents and, as relevant, temperatures occurring in practice. The flow functions represent the variation of unconfined yield strength σc with major consolidation stress σ1 as occurs during storage and flow.

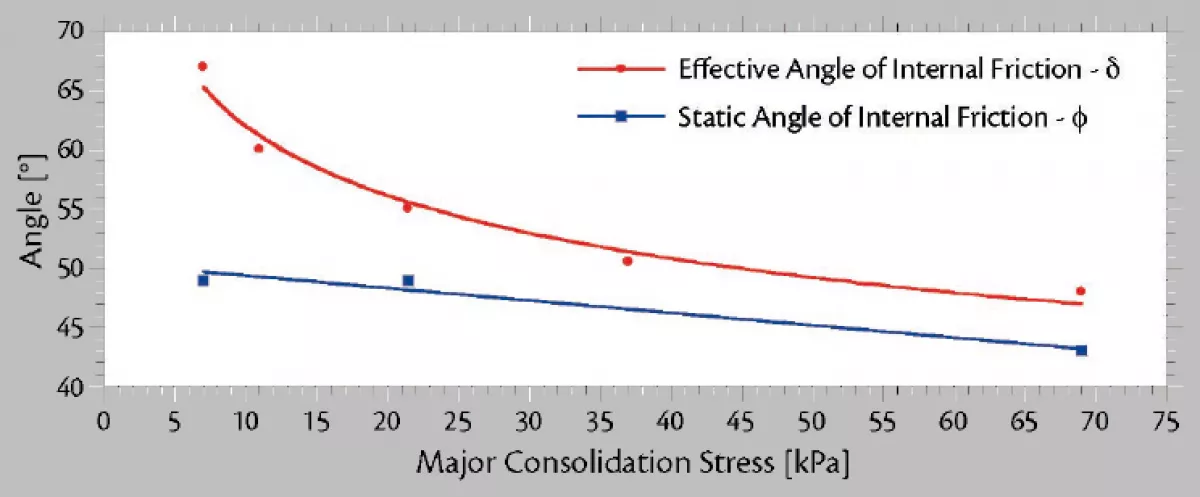

- Effective angle of internal friction δ as a function of major consolidation stress.

- Static angle of internal friction φt as a function of major consolidation stress and time consolidation.

- Wall friction angles φ as a function of normal stress for different bin and chute wall materials and finishes.

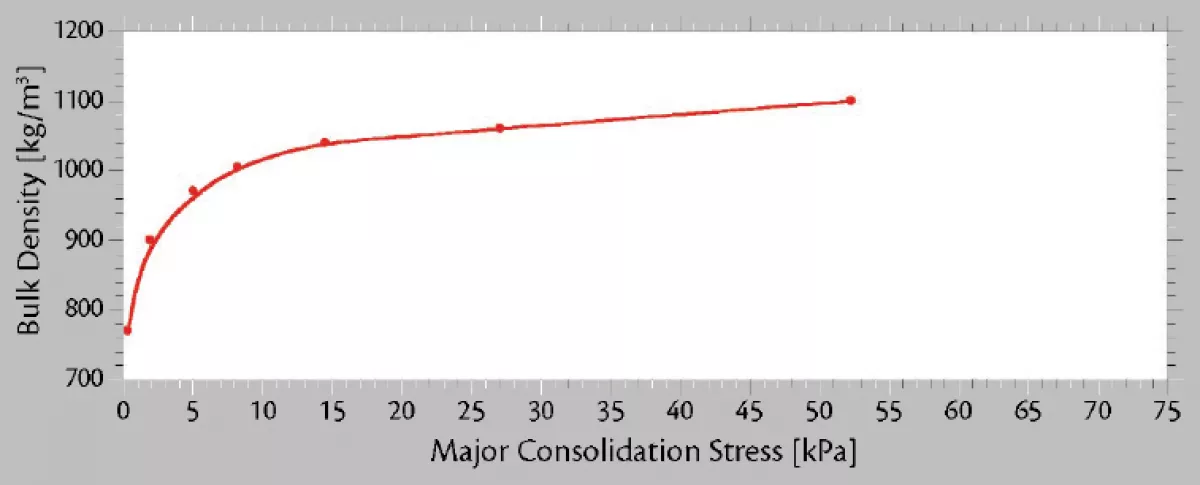

- Bulk density ρ as a function of major consolidation stress.

The foregoing tests are based on the original work of Jenike [5] and have been subsequently documented by others such as by Roberts [6]. A typical set of flow property graphs for a sample of coal are shown in Figs. 1, 2 and 3.