The determination of the quality of purchased or produced goods is depending on the way a representative sample is taken and the preparation of this sample. In-line sampling is crucial to monitor and control the production process. Incorrect taken samples or samples processed in an incorrect way will lead to false analyses, resulting in goods being approved (false positive) or declined (false negative) wrongly.

Implementation

Laarmann Group strongly encourages (bulk processing) companies to implement their own sampling process instead of outsourcing it. Outsourcing this process creates many expenses, just think about the amounts of product that are lost during the process.

To ensure that an external company has a representative amount of material the companies need to send dozens of kilograms, where for the actual chemical analysis they require only a few hundred grams. Apart from the questions whether the external company produces a representative sub-sample, the companies never see the remaining material (the reject) again. The question is what happens with this, often, costly material.

In this way, especially when there are big quantities of precious material, it is most preferred that companies process their own samples. With a good sample preparation process, the amount of sample that needs to be send for analysis can be reduced from dozens of kilograms to a few hundred grams. Processing the samples in house will make it possible to take multiple samples to determine the quality of the bulk even better. Companies who successfully implement this system will save their precious material and reduce their transport cost.

Steel Industry

Laarmann developed a sample processing system for the evaluation of raw materials. Following we look at the production of stainless steel. To manufacture stainless steel you add precise amounts of Chrome, Nickel, Titanium and Molybdenum to Iron. These materials, which represent high value, are bought as Ferroalloys.

Correct evaluation of the metal content within these alloys is crucial when producing stainless steel. A shortage of certain elements will lead to an inferior quality of the produced stainless steel, whereas an excess will only increase the costs of the production.

Size Reduction

To determine the qualities of the Ferroalloys the pieces of alloy (60-70 mm) are sampled and then reduced. The steel company used to reduce the 25 kg of materials using a jaw crusher (reduction down to 10 mm). After primary crushing the operator needed to grab the material from underneath the machine and put it into a rolls crusher where it was further reduced to grit (< 2mm). The sample was send over to an external laboratory for analyses.

Push of a Button

The installation of a sample preparation system has simplified the size reduction process for this steel company to a mere push of a button. Now since there is no more need for the operator to lift any heavy materials or perform multiple actions the process is more efficient, resulting in more samples and an overall higher quality.

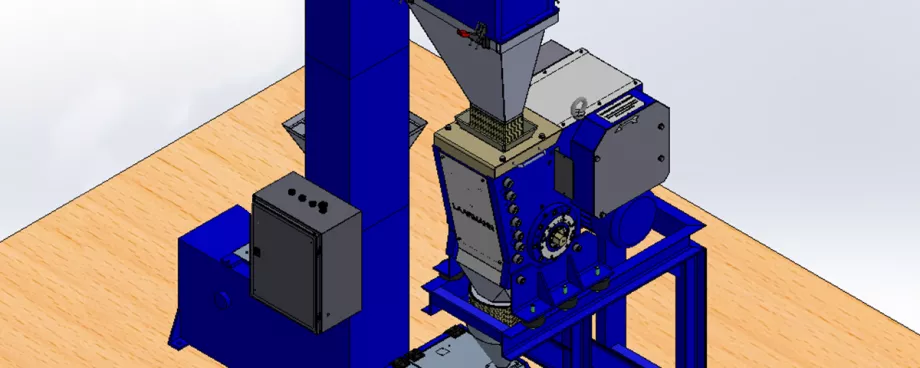

The operator puts 25 kilograms of material in the inlet funnel and starts the process at the central control box. A vibratory feeder underneath the inlet funnel evenly feeds the bucket elevator. The bucket elevator lifts the material and feeds the jaw crusher (type LMFC250) which reduces the material to < 2 mm. Via a flexible connection the grit material is fed to a rotary sample divider which splits the sample in ten equal portions of 2,5 kilograms (sub samples). The alloys feature a density between three and eight g/cm3 giving a partial sample volume of 350 to 800 cm3. Such a sample will then be pulverised in a ring mill (type LM2000) to achieve the desired end finesses of 125 micron. The external lab needs 12 to 15 grams of this product to prepare a tablet to be analysed by an XRF-machine (X-ray fluorescence).

Cleaning

The funnel above the LMFC250 jaw crusher can be moved aside so that the installation can handle smaller quantities of material without contamination of the bucket elevator. Sliding the funnel aside makes the crusher easily accessible for cleaning.

The bucket elevator has multiple hatches which can be opened for cleaning the buckets. Regular cleaning of the bucket elevator will not be necessary, due to the fact that the material entering the bucket elevator is quite big, with only a mimum content of dust.

The integrated rotary sample divider is mobile so it also can be used as a stand-alone machine in the lab. Thanks to the compact design of this installation the space of the laboratory, which often don’t have much space to begin with, is used optimally.

Results

The advantages of the sample processing installation for this steel company can be summarized as follows:

- The amount of material that needs to be sent to an external laboratory is reduced from 25 to a mere 0.4 kg greatly reducing the loss of costly material.

- The working conditions of the operator are considerably improved. His work load has been reduced and he is now wider available for different tasks.

- The efficiency of the installation allows more samples to be taken, improving the overall quality and representability of the process.

- A more accurate analysis of the purchased good triggers the suppliers to deliver the high quality raw material. Delivered inferior quality material will be spotted at an early stage.

- The system can be operated in an oxygen free environment thus eliminating the chances for explosions which is common for some Ferroalloys.

■