Technical Ceramics

Technical ceramics

Advanced ceramic materials make applications possible today that were virtually inconceivable just yesterday. Due to their unique material properties, technical ceramics are considered to be one of the most efficient materials of our time.

Advanced ceramics provide the basis for FUBOON products. This material is also referred to as technical ceramics, engineering ceramics or industrial ceramics. These terms cover many different and in part highly-specialized ceramic materials with unique mechanical, electrical, thermal and biochemical properties and property combinations.

These specific characteristics can be further developed, optimized and matched for use in technical applications. It is also possible to combine different properties. Materials like these can be used to design advanced components that perform the required tasks with optimum precision and can be light years ahead of competing materials such as metal or plastic in the respective field of application. Components made from ceramic materials are increasingly the only solution available for technical challenges that cannot be overcome with conventional materials.

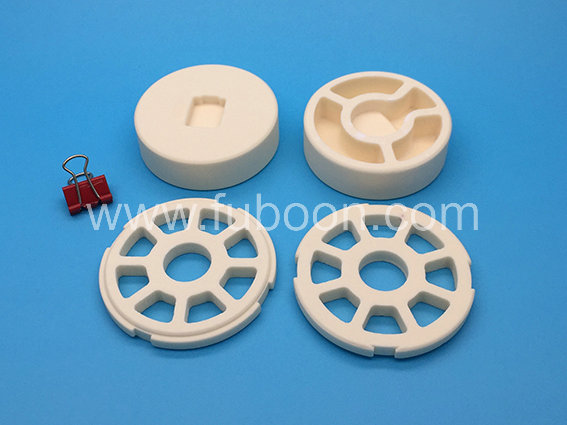

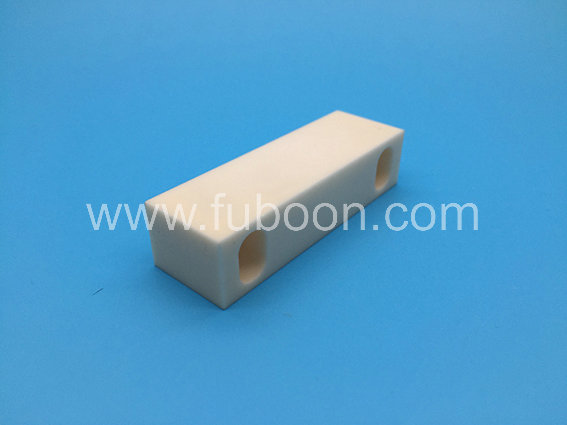

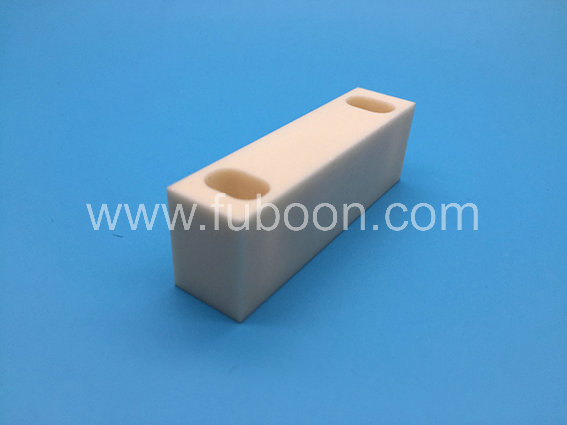

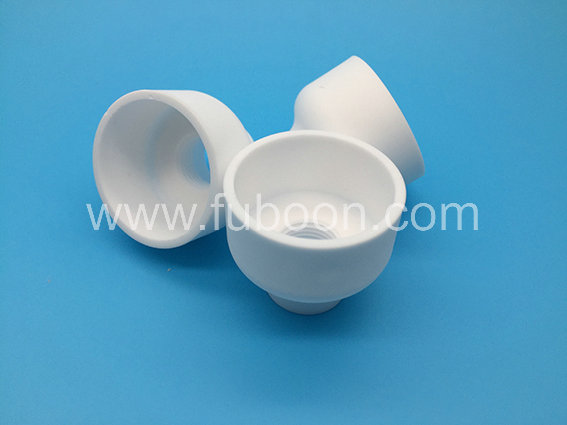

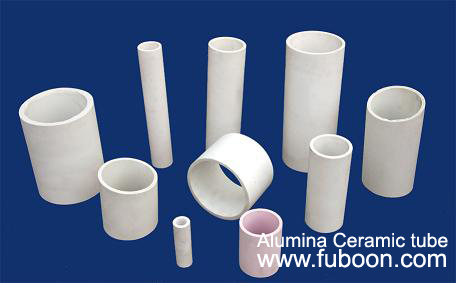

Gallery:

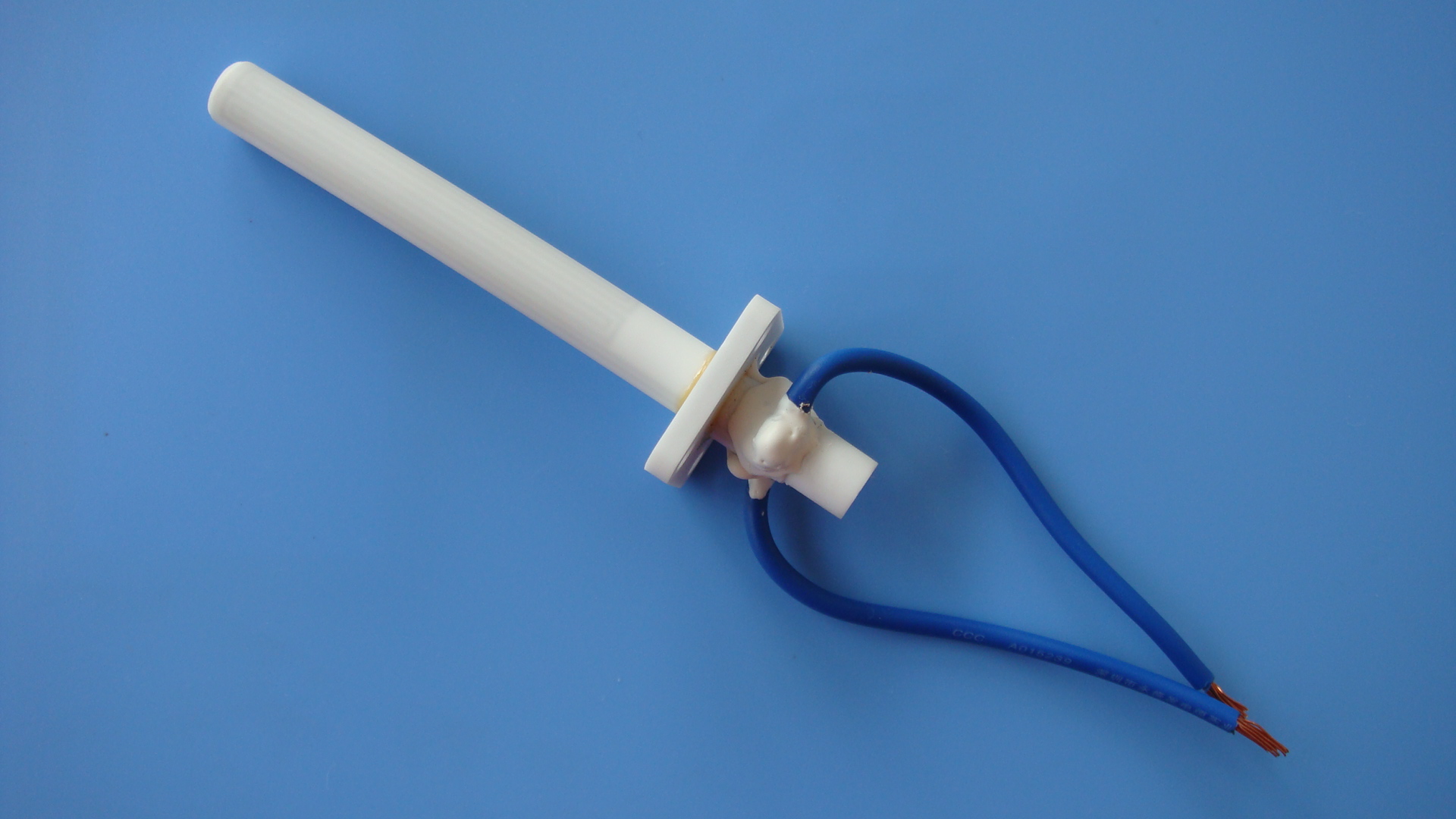

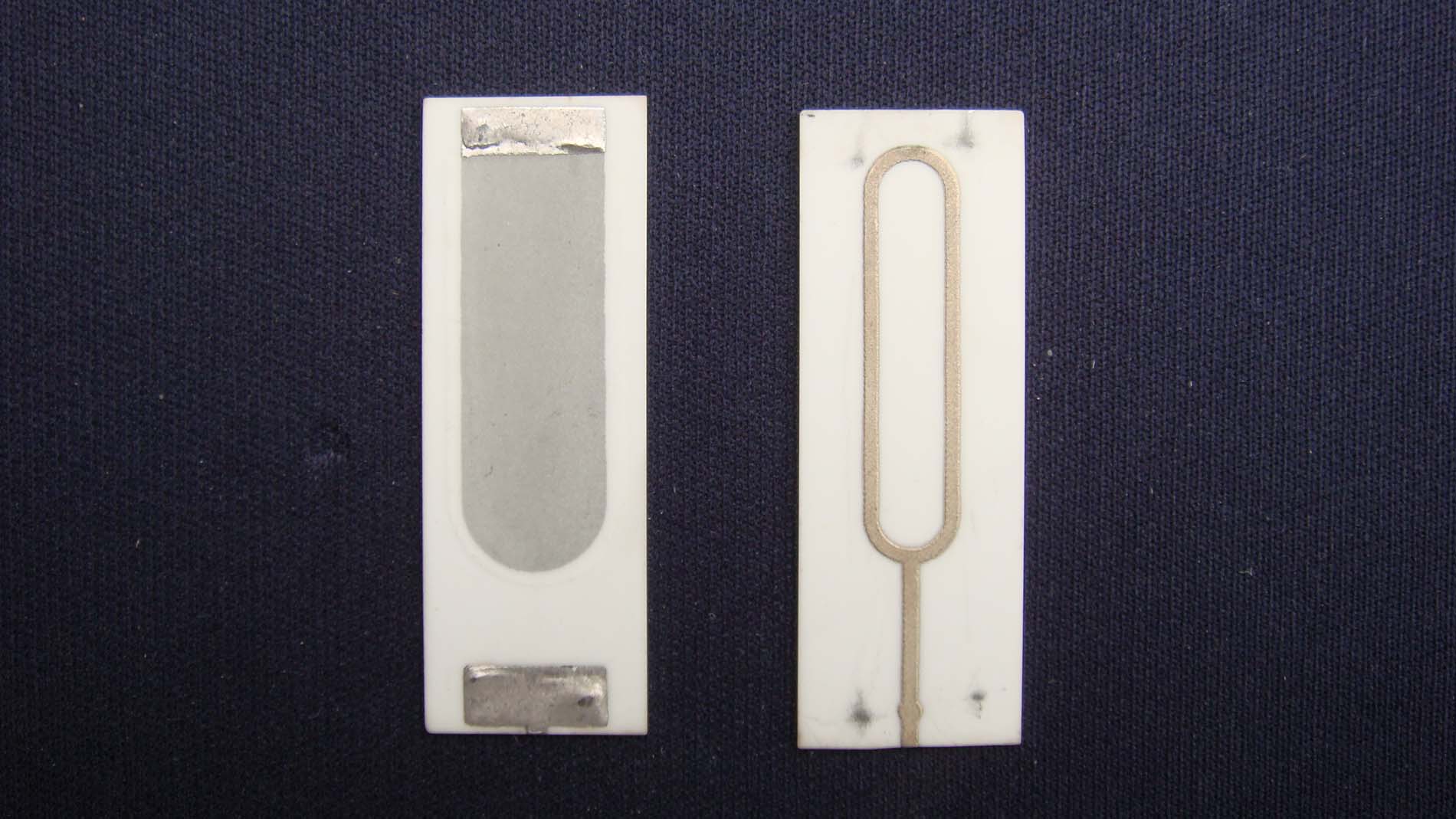

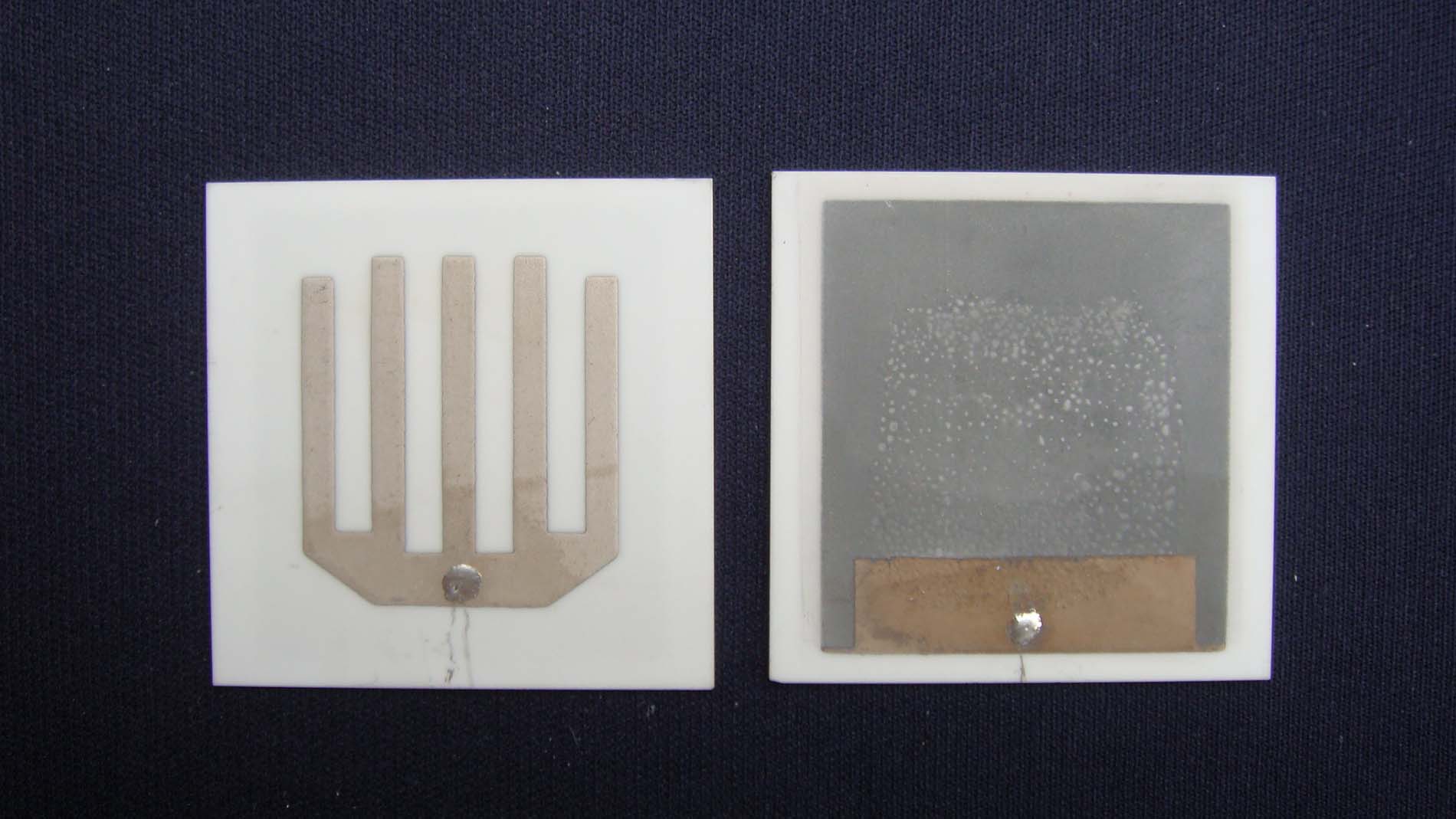

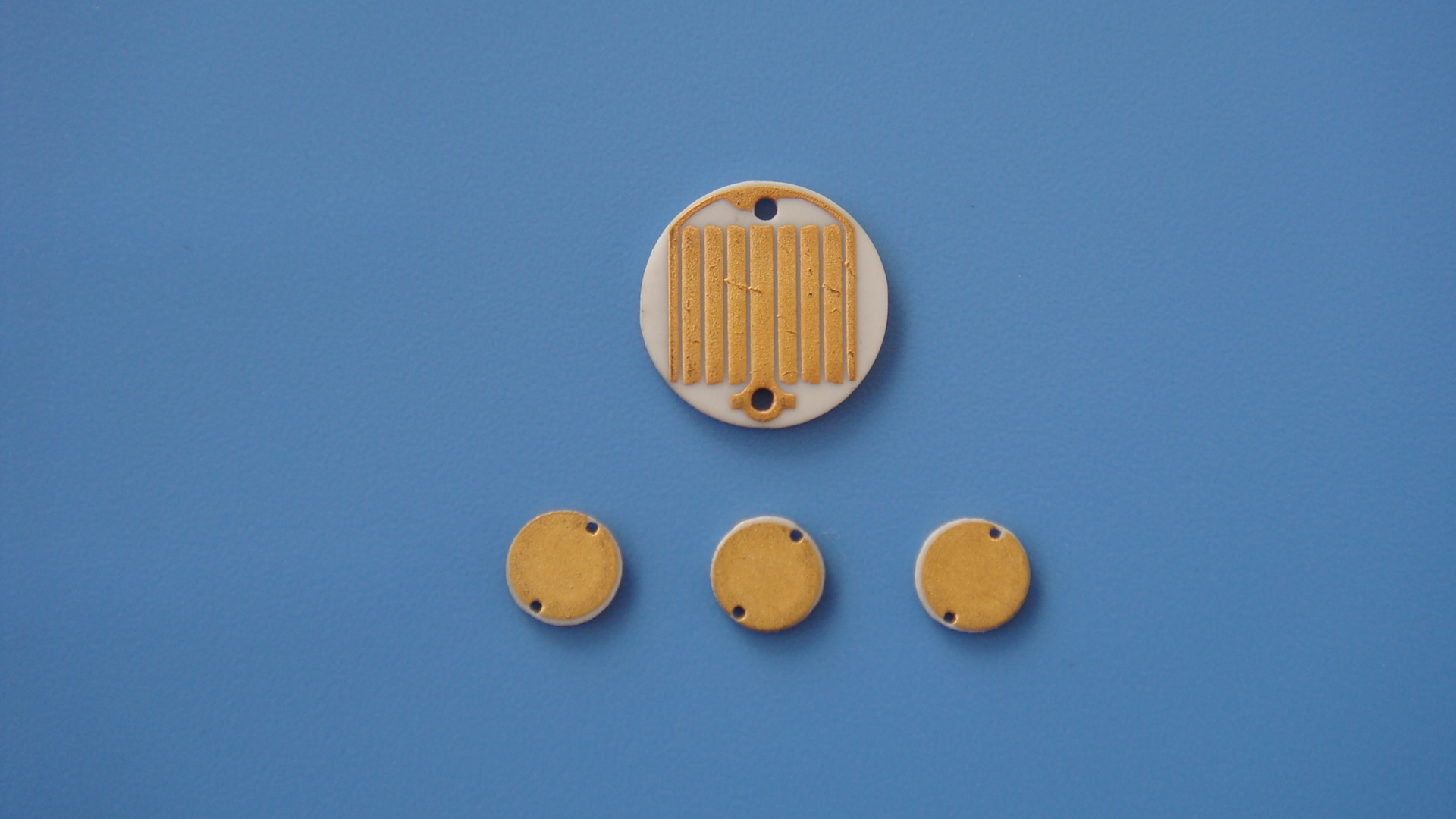

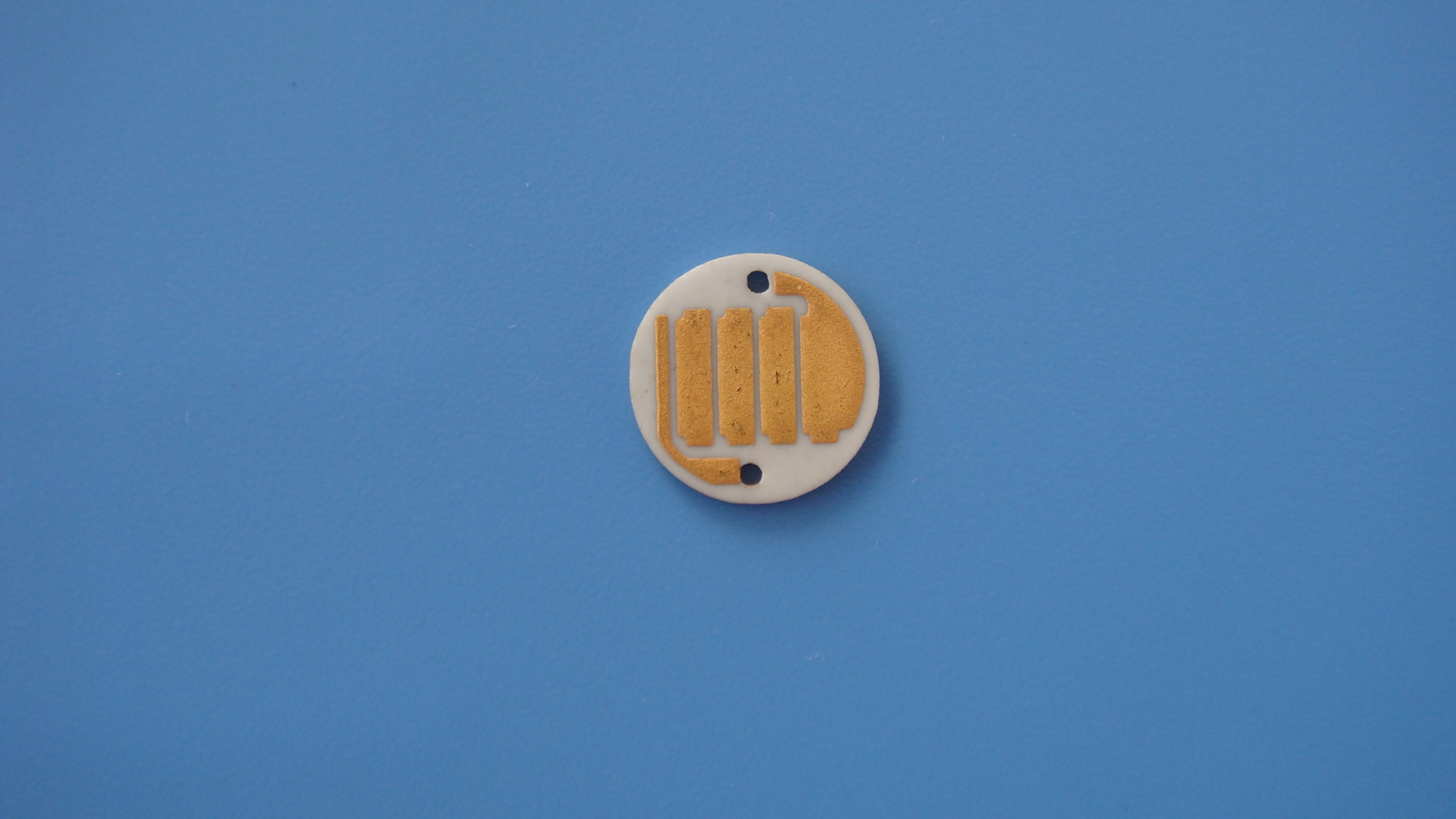

Ceramic Heaters

This material is also referred to as technical ceramics, engineering ceramics or industrial ceramics. These terms cover many different and in part highly-specialized ceramic materials with unique mechanical, electrical, thermal and biochemical properties and property combinations.

These specific characteristics can be further developed, optimized and matched for use in technical applications. It is also possible to combine different properties. Materials like these can be used to design advanced components that perform the required tasks with optimum precision and can be light years ahead of competing materials such as metal or plastic in the respective field of application. Components made from ceramic materials are increasingly the only solution available for technical challenges that cannot be overcome with conventional materials.

Technical Ceramics – Materials Groups

Fuboon technical ceramics can be divided into four major groups of ceramic materials: Silicate ceramics, oxide ceramics, non-oxide ceramics and piezo-ceramics. Silicate ceramics are the oldest type of ceramic materials for technical applications and are made primarily from natural raw materials in conjunction with alumina (aluminum oxide, aluminum silicate). The oxide ceramics group contains materials that consist primarily of metal oxides such asaluminum oxide, zirconium oxide, aluminum titanate or dispersion ceramics. Non-oxide ceramics represent a materials group comprised of ceramic materials based on carbon, nitrogen and silicon compounds such as silicon carbide, silicon nitride and aluminum nitride. Piezo-ceramics (also known as functional ceramics) represent a group of materials used to convert mechanical parameters into electrical parameters or, conversely, to convert electrical signals into mechanical movement or vibration.

Technical Ceramics – Material Properties

Ceramic materials used as technical ceramics or advanced ceramics in technical applications must satisfy extremely high demands in terms of their properties. The property spectrum ranges from wear and heat resistance, temperature and corrosion resistance all the way to biocompatibility and food compatibility.

• Flexural strength

• Biocompatibility

• Chemical resistance

• Density and stiffness (Young’s modulus)

• Compressive strength

• Electrical insulation

• Dielectric strength

• Hardness

• Corrosion resistance

• Food compatibility

• Piezo-electricity and dynamics

• Temperature resistance

• Thermal shock and fluctuation resistance

• Metalization (joining technology)

• Wear resistance

• Thermal expansion

• Thermal insulation

• Thermal conductivity

These diverse properties make it possible to use technical ceramics in a variety of applications in the automotive industry, electronics, medical technology, energy and environment and in general equipment and mechanical engineering.

Markets and Applications

Are Nearly Everywhere.

The advanced ceramics offer so many advantages in so many different applications in a wide variety of markets. The products arranged according to market, are used in Vehicle and Automotive Engineering, Electronics, Energy and Environment, Equipment and Mechanical Engineering, and Medical Technology.

Ceramic heaters:

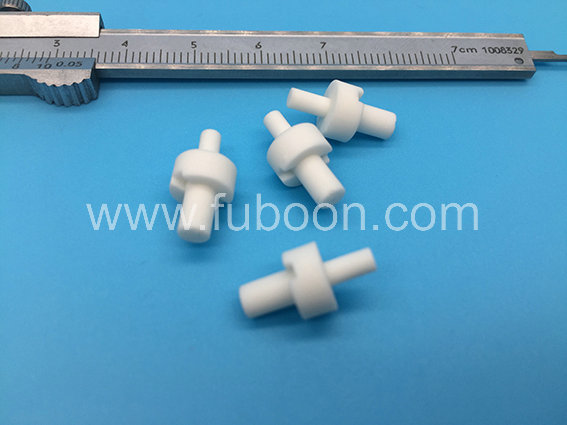

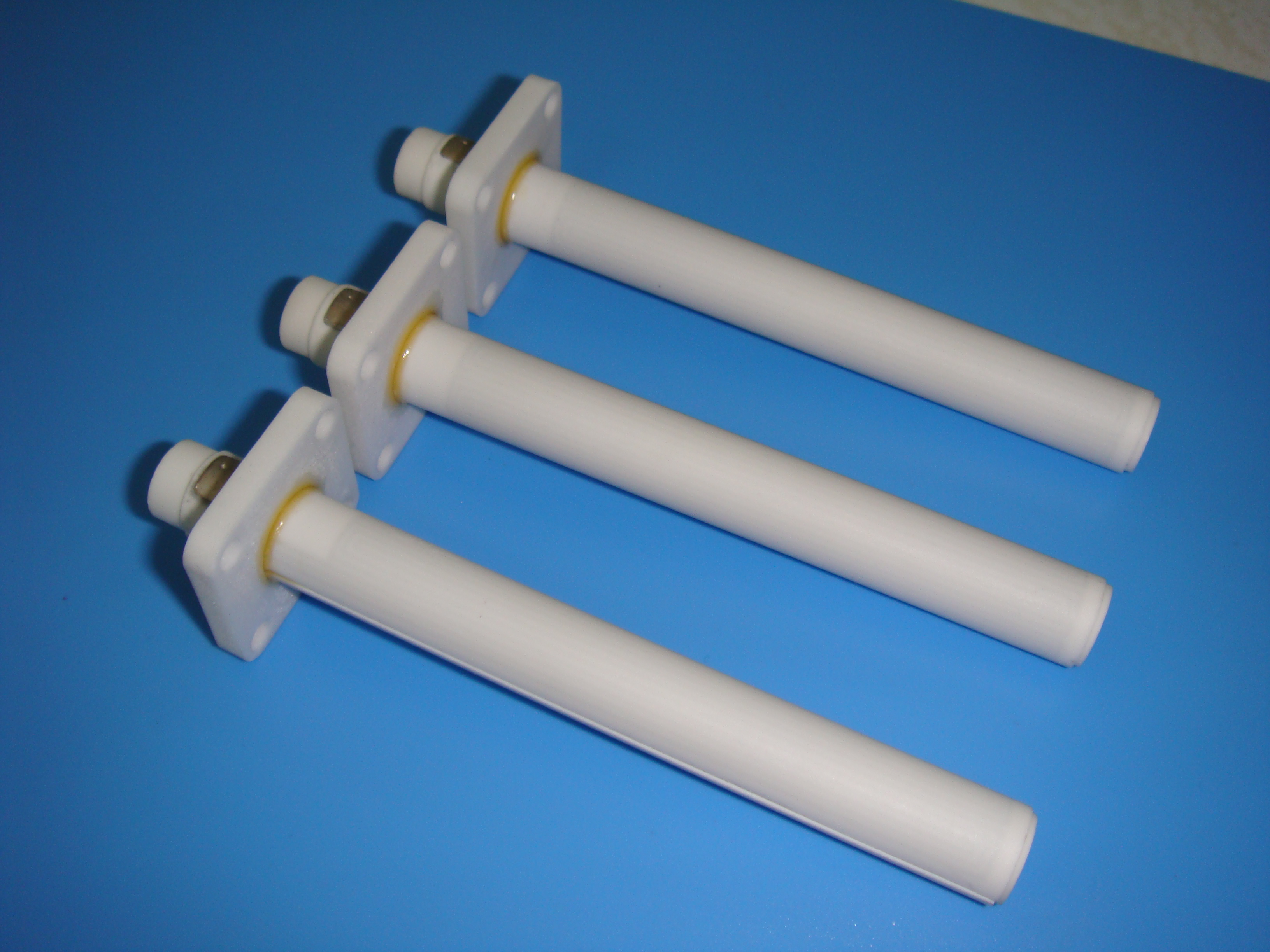

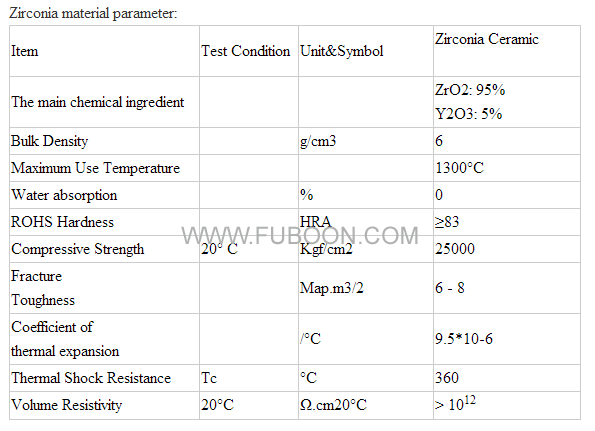

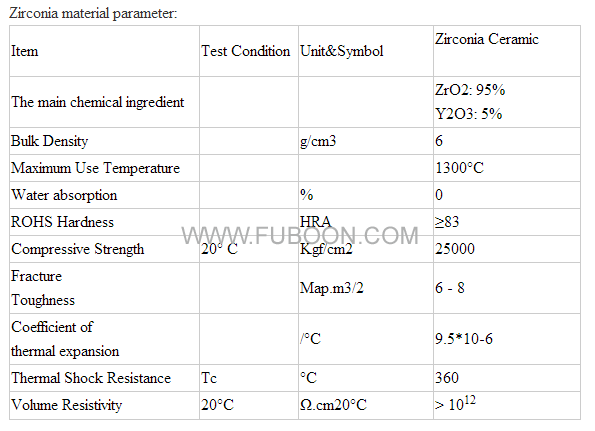

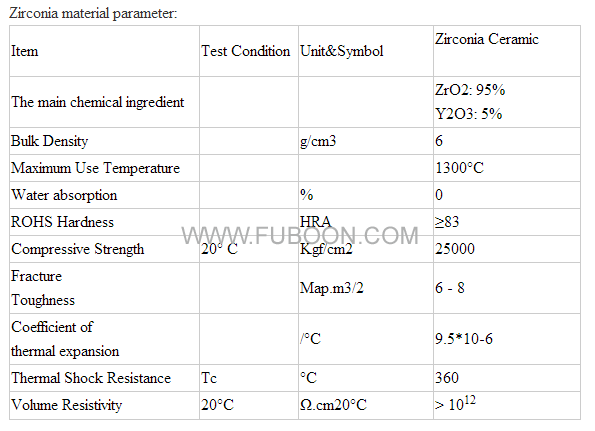

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

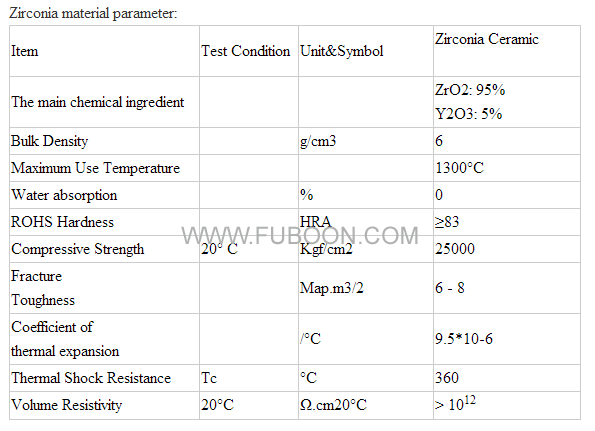

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

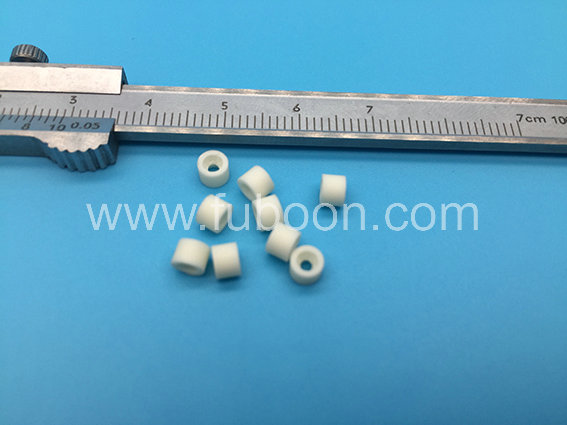

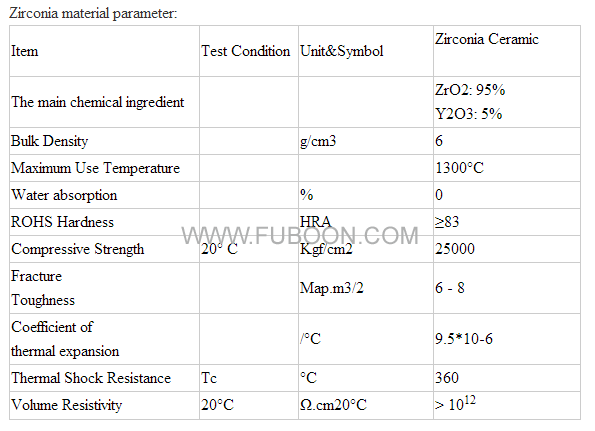

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

FUBOON Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

5.no abrade

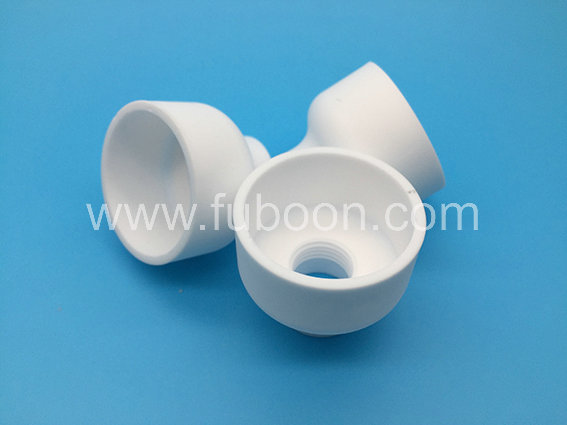

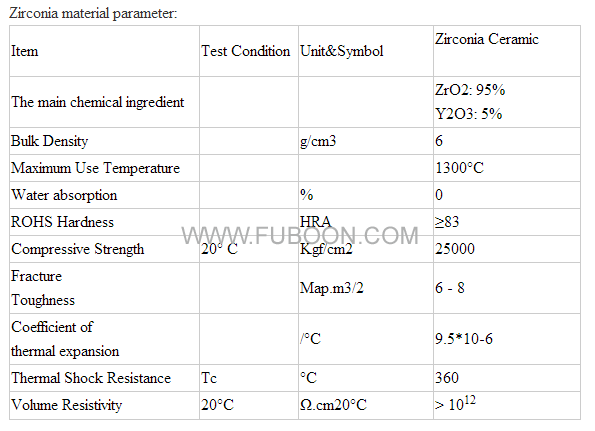

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

FUBOON Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

5.no abrade

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

FUBOON Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

5.no abrade

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/Ceramic Piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

FUBOON Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely

used in structure ceramic areas. Mainly products:tube,pipe,special part, Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia

moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Specifications

1.high toughness

2.high bending strength

3.high abrade-resistance

4.high quality with low price

5.no abrade

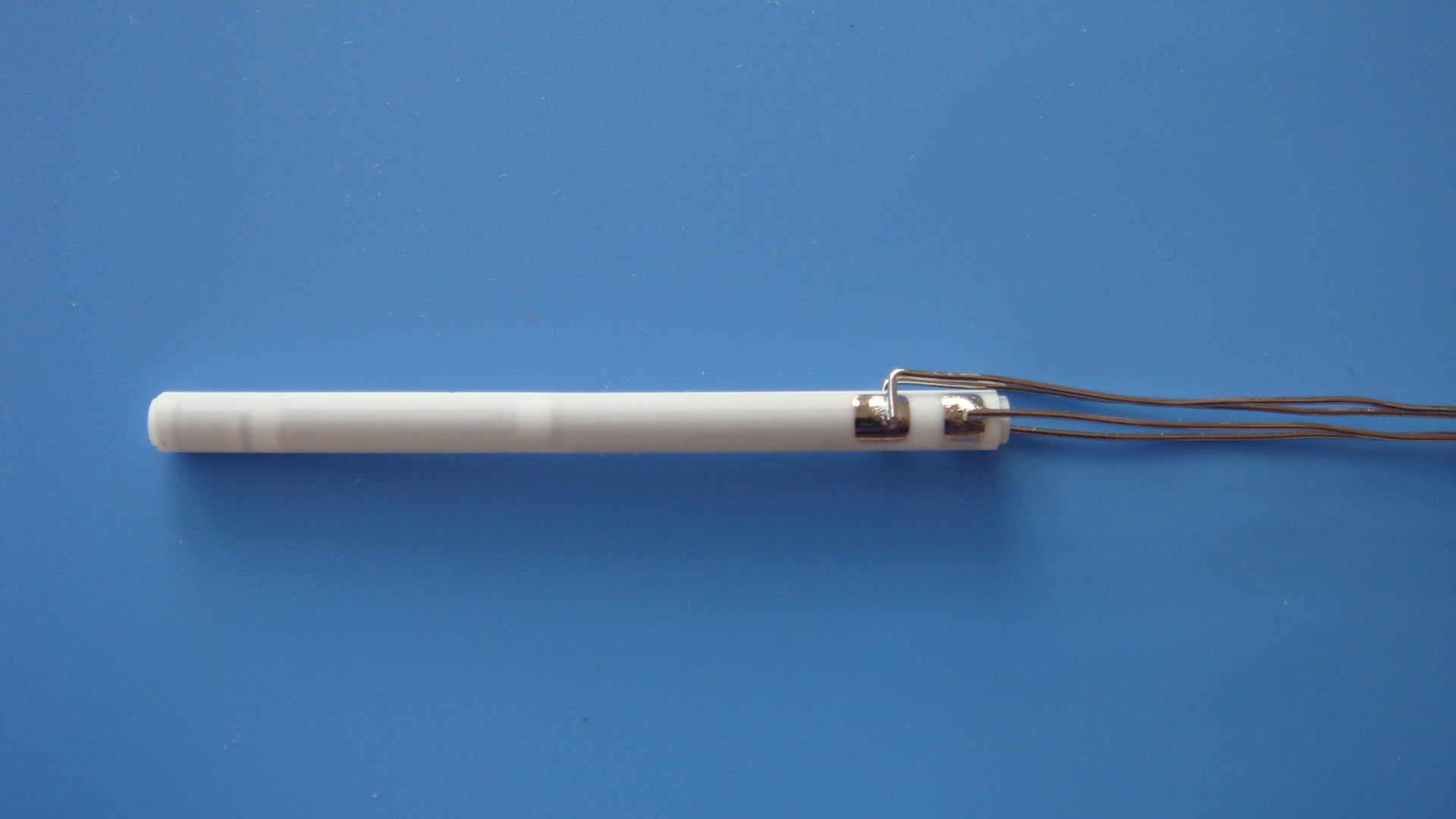

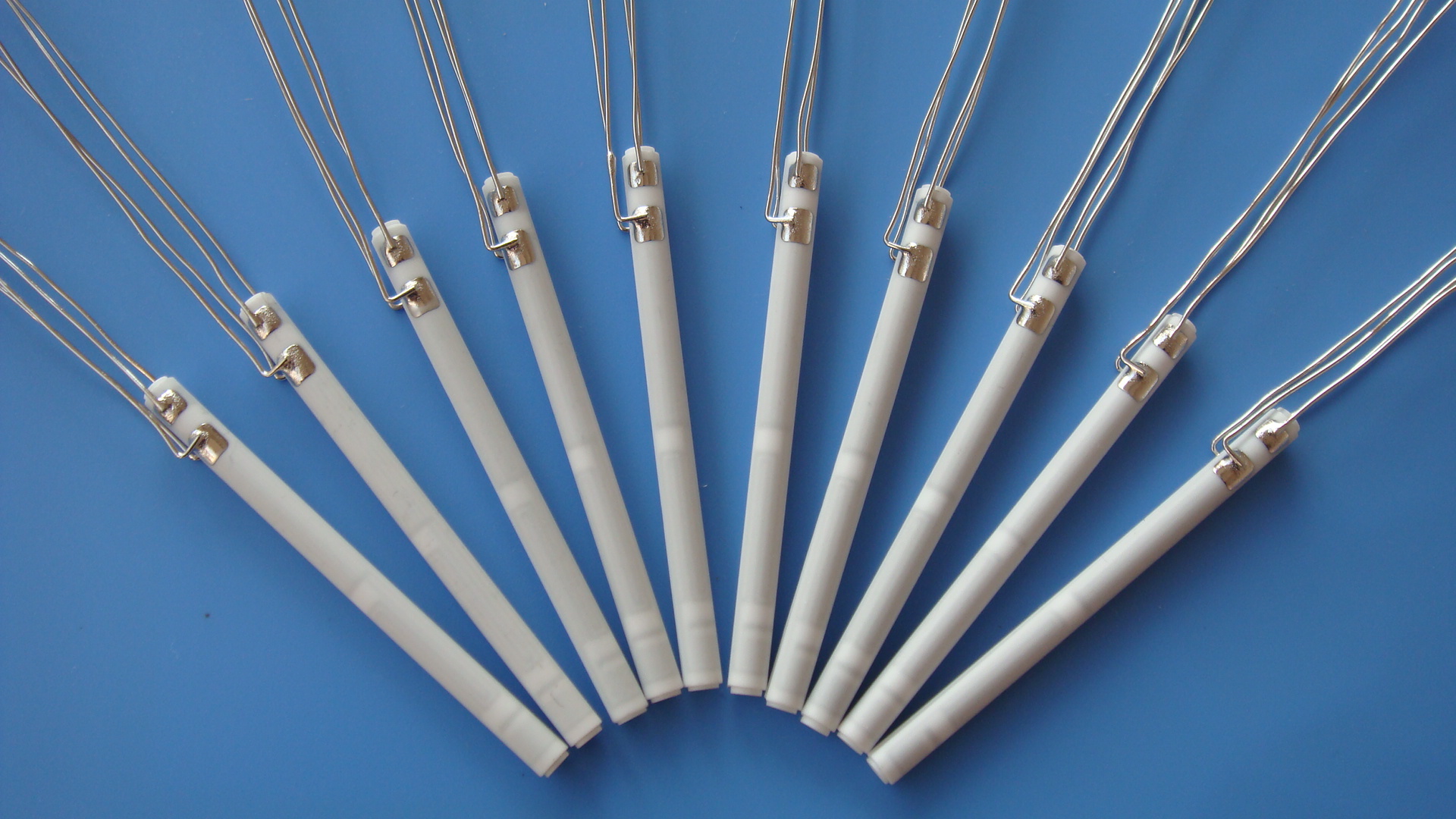

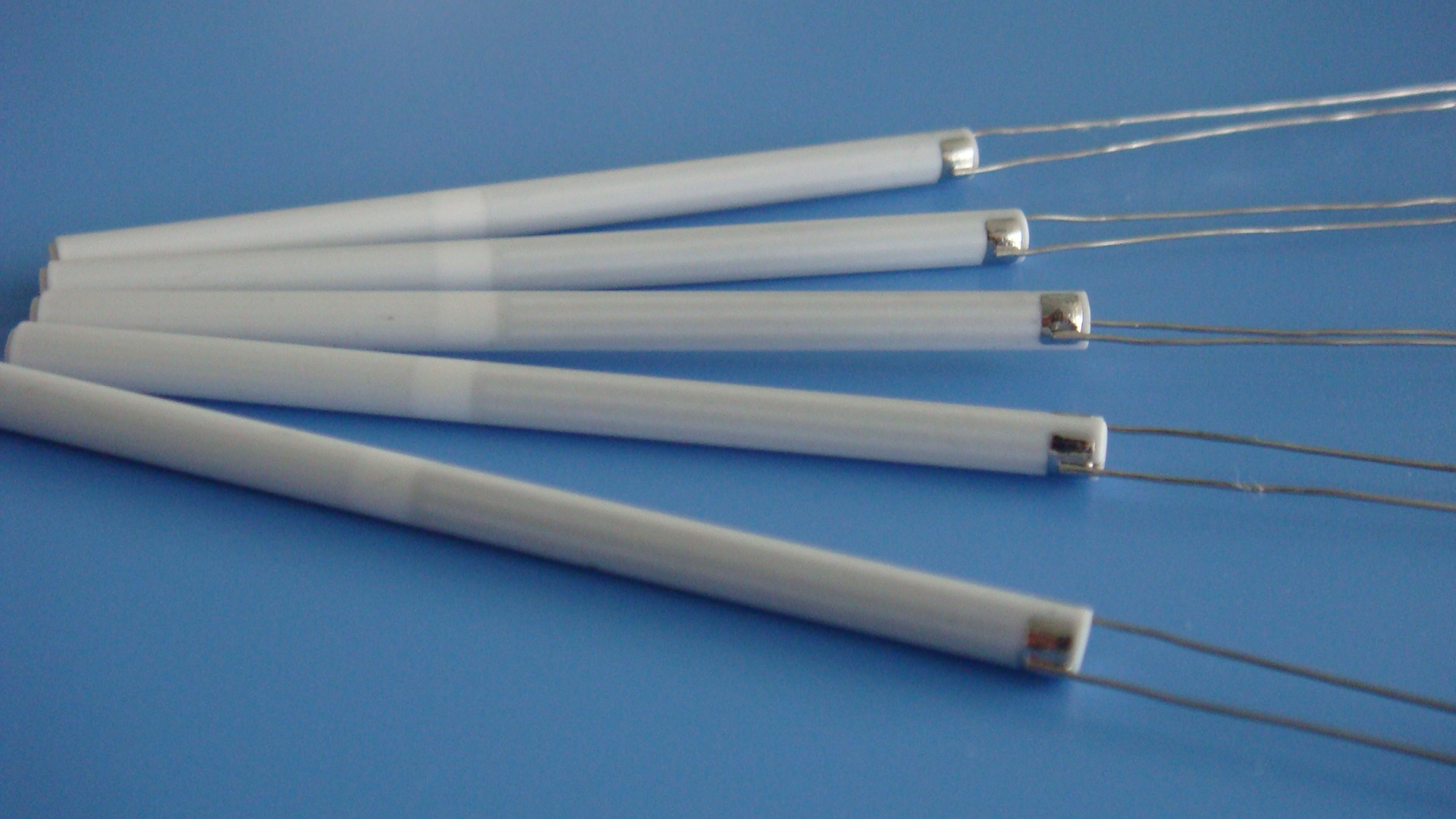

Ceramic Heating Element For O2 Sensor

CERAMIC HEATER

Ceramic Heater Element for Pellet Stoves

Ceramic O2 Sensor Heater For Automobile Exhaust System

NTK Zirconia Chip Heating Plate for Oxygen Sensor

Ceramic Heater Element with Thermocouple

and etc... ■

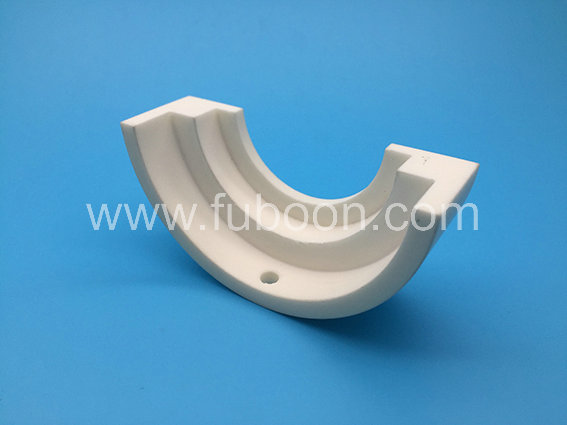

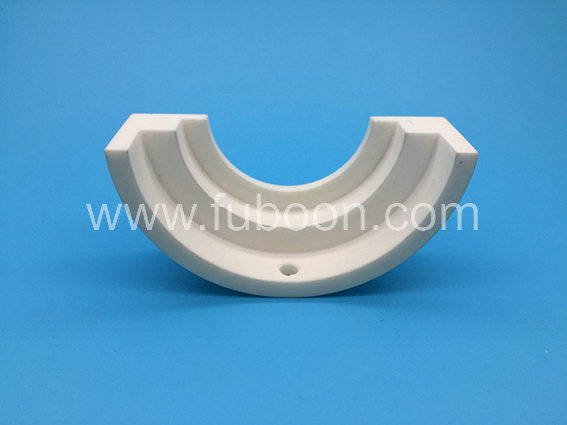

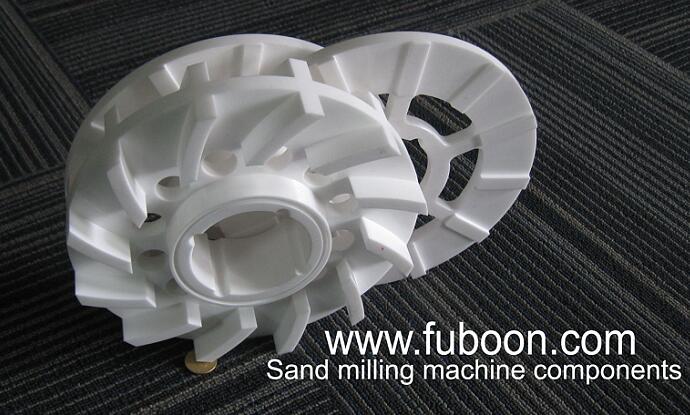

Technical Ceramics for machine and equipment components

Fuboon advanced ceramic materials make applications possible today that were virtually inconceivable just yesterday. Due to their unique material properties, technical ceramics are considered to be one of the most efficient materials of our time.

This material is also referred to as technical ceramics, engineering ceramics or industrial ceramics. These terms cover many different and in part highly-specialized ceramic materials with unique mechanical, electrical, thermal and biochemical properties and property combinations.

These specific characteristics can be further developed, optimized and matched for use in technical applications. It is also possible to combine different properties. Materials like these can be used to design advanced components that perform the required tasks with optimum precision and can be light years ahead of competing materials such as metal or plastic in the respective field of application. Components made from ceramic materials are increasingly the only solution available for technical challenges that cannot be overcome with conventional materials.

Technical Ceramics – Materials Groups

Fuboon technical ceramics can be divided into four major groups of ceramic materials: Silicate ceramics, oxide ceramics, non-oxide ceramics and piezo-ceramics. Silicate ceramics are the oldest type of ceramic materials for technical applications and are made primarily from natural raw materials in conjunction with alumina (aluminum oxide, aluminum silicate). The oxide ceramics group contains materials that consist primarily of metal oxides such asaluminum oxide, zirconium oxide, aluminum titanate or dispersion ceramics. Non-oxide ceramics represent a materials group comprised of ceramic materials based on carbon, nitrogen and silicon compounds such as silicon carbide, silicon nitride and aluminum nitride. Piezo-ceramics (also known as functional ceramics) represent a group of materials used to convert mechanical parameters into electrical parameters or, conversely, to convert electrical signals into mechanical movement or vibration.

Technical Ceramics – Material Properties

Ceramic materials used as technical ceramics or advanced ceramics in technical applications must satisfy extremely high demands in terms of their properties. The property spectrum ranges from wear and heat resistance, temperature and corrosion resistance all the way to biocompatibility and food compatibility.

• Flexural strength

• Biocompatibility

• Chemical resistance

• Density and stiffness (Young’s modulus)

• Compressive strength

• Electrical insulation

• Dielectric strength

• Hardness

• Corrosion resistance

• Food compatibility

• Piezo-electricity and dynamics

• Temperature resistance

• Thermal shock and fluctuation resistance

• Metalization (joining technology)

• Wear resistance

• Thermal expansion

• Thermal insulation

• Thermal conductivity

These diverse properties make it possible to use technical ceramics in a variety of applications in the automotive industry, electronics, medical technology, energy and environment and in general equipment and mechanical engineering.

Markets and Applications

Are Nearly Everywhere.

The advanced ceramics offer so many advantages in so many different applications in a wide variety of markets. The products arranged according to market, are used in Vehicle and Automotive Engineering, Electronics, Energy and Environment, Equipment and Mechanical Engineering, and Medical Technology.

Attachments

179491d1472700142t-technical-ceramics-machine-equi (JPG)

■