Re: Bucket Elevator Motor Power Calculation

Dear Mr. lazsalo,

The bucket elevator power requirement is calculated firstly by deciding the tractive pull. The tractive pull is made of up of two components :

- The weight of material in carrying run of the bucket elevator. This is to be calculated by material weight in each bucket multiplied by the number of buckets on carrying run.

- The material scooping resistance. The scooping resistance is applicable to centrifugal discharge type of elevator (this is also called spaced bucket elevator). The scooping resistance for continuous type pf bucket elevators is generally not applicable, but still one may consider it about 20% of value for space type of bucket elevator. In case of space type of bucket elevator the scoop resistance is considered equal to material weight in certain height of carrying run. The scooping resistance depends upon the material. One of the practices is to consider this resistance as equivalent to 4.5 m height for easy material, about 5.5 m for crushed coal type of material, about 7 m for fine stone and about 9 m for coarse stone type of material.

Above will enable you to calculate the tractive pull attributed to lift and scooping. This tractive pull multiplied by the bucket speed will give you the power. If the tractive pull is in kgf and if the bucket speed is in m/sec then power (kW) required would be product of these two quantities divided by 102. In case the pull is in N and speed is in mps then power (kW) would be product of these two quantities divided by 1000. Then one has to add for bucket elevator efficiency say 95% etc. and then efficiency of the drive system.

In case you wish to derive the power just because of the lift, then the formula which I remember is (ton/hr) x (height in feet) divided by 884 will give you the horsepower. The mentioned ton correspond to one ton = 2240 pounds.

Regards,

Ishwar G Mulani.

Author of Book : Engineering Science and Application Design for Belt Conveyors.

Author of Book : Belt Feeder Design and Hopper Bin Silo

Advisor / Consultant for Bulk Material Handling System & Issues.

Email : parimul@pn2.vsnl.net.in

Tel.: 0091 (0)20 25882916 ■

Re: Bucket Elevator Motor Power Calculation

"Back of an envelope" calculation :

Power = (Lift + 10) * Capacity / 330

Power in kW

Lift in m

Capacity in tonne/hr

Round up to get your motor size. ■

Re: Bucket Elevator Motor Power Calculation

Hello,

Referring to Osamabadr555 question about power calculation, it will be more easy to understand the issue by following numerical example, instead of describing in abstract manner.

1.0 Application (requirement) data

Elevator: Vertical

Elevator c/c height: 25 m

Capacity guaranteed Qg: 7 mtph. This is legally guaranteed capacity to be demonstrated during acceptance trial.

Material (assumed): Coal, bulk density 0.8 tonne / cubic metre i.e. 0.8 kg/litre, size less than 10 mm

2.0 Stage - 1: Technical features

Prior to making any design, the designer has to choose certain technical features as below by assumption or by experience or by trail and error; without which power calculation cannot be proper / useful.

2.1 Decision – 1: Elevator type centrifugal chain bucket elevator is suitable for the concerned material. This decision requires knowledge of various type of bucket elevators.

2.2 Decision - 2, about likely model / size: Bucket size 8 inch x 5 inch x 5.5 inch (200 mm x 125 mm x 140 mm). Buckets spacing 16 inch (400 mm). This decision also needs knowledge of bucket elevators, or production range. For the stated bucket, the volumetric capacities are as below (from buckets leaflet).

Bucket stuck volume capacity: 2.0 litre (i.e. upto brim)

Bucket water level volume capacity: 1.2 litre

2.3 Decision - 3: The coal is average material, and elevator being centrifugal type, scoop load is considered equivalent to approx 5 m height.

3.0 Solution:

It is advisable to consider design capacity 10 to 15% more for safety against commercial penalty, due to unexpected situation.

Design capacity Qd = 7 x 1.15 say 8 mtph

Bucket fill factor 75% in relation to design capacity, and centrifugal type elevator.

3.1 Checking for chosen model suitability for design capacity:

Material in each bucket: 0.75 x 2.0 x 0.8 = 1.2 kg

Number of discharges in one hour = 1.1 mps x 3600 / 0.4 = 9900

Elevator capability for capacity: 9900 x 1.2 = 11880 kg/hour i.e. 11.88 mtph > 8 mtph OK. The elevator being of very small capacity, there is no other model closer to required design capacity.

3.2 Power calculation for motor sizing:

As per practice in India and USA (and thereby may be also Europe), drive motor power is sized, considering buckets filled to brim (stuck volume). Such thing can happen due to improper feeder or operational anomaly. Accordingly:

Material in bucket = 2.0 x 0.8 = 1.6 kg

Number of buckets on carrying side (for power) = (25 + 5) / 0.4 = 75 nos.

Total material in buckets i.e. for material lift resistance = 1.6 x 75 = 120 kgf or 120 x 9.81 = 1177 N.

Adding 7.5 to 10% for losses at sprocket, etc. Resistance = 1177 x 1.075 = 1265 N.

Elevator power at drive shaft = 1265 x 1.1 / 1000 = 1.39 kW

Drive efficiency say 80%

Therefore, required power at motor shaft = 1.39 / 0.8 = 1.74 kW

One can use 2.2 kW motor

3.3 Power calculation for known mtph:

This can be easily calculated by following direct method, to know power for design capacity

Material mass per metre of height = 8 mtph / (3.6 v) = 8 / (3.6 x 1.1) = 2.02 kg/m

Lift resistance = 30 m x 2.02 = 60.6 kgf

Adding 7.5 % for sprockets, etc., resistance = 60.6 x 1.075 = 65.15 kgf i.e. 65.15 x 9.81 = 639 N

Therefore, power at drive shaft = 639 x 1.1 / 1000 = 0.7029 kW

Power consumption at motor shaft = 0.7029 / 0.8 = 0.8786 kW

4.0 Bucket water level capacity:

Some designer (or user), particularly while dealing with very free flowing material, prefer that chosen bucket elevator should be capable to ensure guaranteed capacity, on the basis of water level capacity of bucket. In such case bucket water level capacity become useful.

5.0 General:

As for general information, bucket elevator power calculation is simplest compared to other equipment . Mainly it is just material lifting power against gravity, wherein kW = Q.H/367 where Q is mtph, H is vertical lift (or elevator lift + scoop resistance equivalent lift). Then enhance this value by sprocket resistance and drive efficiency factors.

Accordingly, power consumption at 8 mtph = (8 x 30 / 367) x 1.075 / 0.8 = 0.8787 kW

Same as before, simple !

In general it is difficult and not advisable to describe design procedure in forum, as it cannot cover all aspects, and hence I avoid it, as a rule. Also there is possibility of misquote in contractual dispute. So the information here to be treated as ‘non specific’ and open to differing views.

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Re: Bucket Elevator Motor Power Calculation

3.2 Power calculation for motor sizing:

As per practice in India and USA (and thereby may be also Europe), drive motor power is sized, considering buckets filled to brim (stuck volume). Such thing can happen due to improper feeder or operational anomaly. Accordingly:

Material in bucket = 2.0 x 0.8 = 1.6 kg

Number of buckets on carrying side (for power) = (25 + 5) / 0.4 = 75 nos.

Total material in buckets i.e. for material lift resistance = 1.6 x 75 = 120 kgf or 120 x 9.81 = 1177 N.

Adding 7.5 to 10% for losses at sprocket, etc. Resistance = 1177 x 1.075 = 1265 N.

Elevator power at drive shaft = 1265 x 1.1 / 1000 = 1.39 kW

Drive efficiency say 80%

Therefore, required power at motor shaft = 1.39 / 0.8 = 1.74 kW

One can use 2.2 kW motor

Thanks sir for your replying on my question about calculate the motor power of bucket elevator on web link :-

https://forum.bulk-online.com/showth...er-Calculation

But there's some inquiries(questions)

I followed your explain to calculate motor power as the following [ 3.2 Power calculation for motor sizing ]to calculate the motor power to bucket elevator I have which its details as following:-

Material type:wheat

Capacity:- 8 t/hr

No. Of buckets per meter:-4

Buckets type:-metal

Wt. Of bucket filling with wheat till its brim(bucket+wheat):-1.4 kg

Vertical height:-25m

But why sir :-

-you use 80% as a drive efficiency and divided power at drive shat on its value not multiplied?

-you add 5 to height and divided on 0.4

What 0.4 mean?

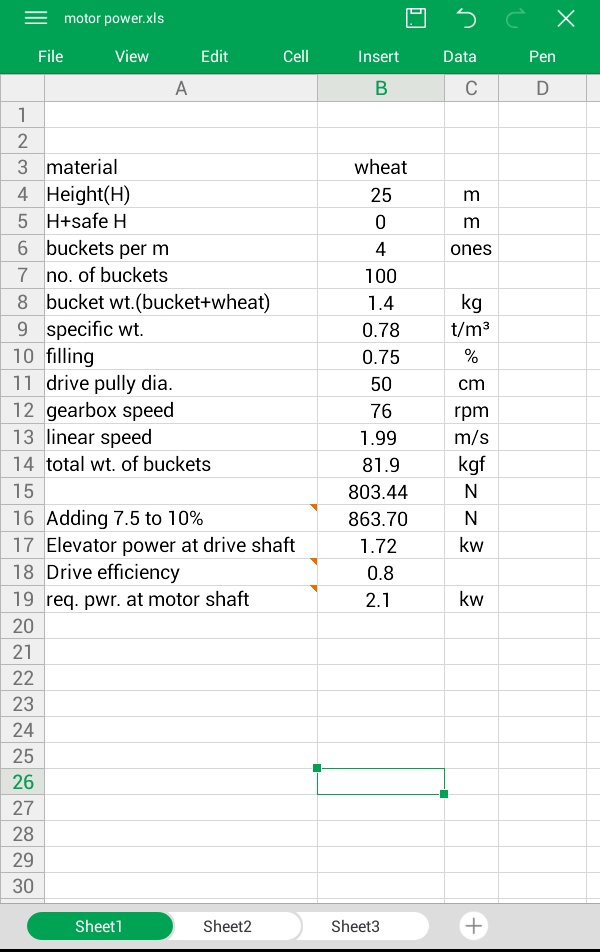

As a picture attached I calculated motor power ■

What Goes Down Must Come Up.

Osama,

If the required power at the drive shaft had been multiplied by the efficiency then energy would have been created.

Nought point four relates to the bucket spacing.

Material differences e.g. wheat versus coal, only affect the filled density in the bucket. A tonne of coal weighs the same as a tonne of wheat.

This thread has been answered many times with very simple straightforward equations which are quite valid. If you wish to complicate the replies the only possible discrepancy is in the selection of the digging allowance which has already been offered in a previous reply. It is now possible to provide accurate and cost effective test data for realistic digging resistances. This will eliminate guesswork for all concerned.

Happy New Year! ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Refinement

Apologies!

Some elevator arrangements discharge onto the descending bucket ahead in the returning sequence.

This downfall effect will very very mildly reduce the carrying side tension.

That is one less downfall (Ho Ho Ho.) for me anyway. No doubt there will be other discrepancies when we look hard enough. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Calculation Motor Power

Please sir

If I have buckets elevator which is its details

Height=25 meter

Capacity=7 ton/hour

Bucket volume=0.003 m

Number of buckets per meter=4

What's the power of motor available to this elevator?

How can I calculate that? ■

Re: Bucket Elevator Motor Power Calculation

Thanks a lot

But if I have bucket elevator which its height 25 meter and material rate 8 ton/hour

Used to convey wheat

What's its motor power ? ■

Substituting For...

Both short form equations indicate a power demand of around 0.72 or 0.85kW which rounds up to 1.1kW motor frame to accommodate drive efficiency and digging.

Eight tonnes of wheat per hour sort of indicates that a bucket elevator small enough for the task will cost a lot more than an off the shelf item with internal cables joining circular discs.....not mentioning any names...which are very often advertised on the forum pages.

Sometimes it would be appreciated if folk read the adverts before asking the questions. Speaking of questions: how would you reasonably pack a 300cm3 bucket and then match them to a small enough belt? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Bucket Elevator

Dear Experts,

Seeking a help for bucket elevator. Design Capacity: 50Tph, Material to be conveyed: Quartz 0 - 1mm, Height: 18.5 meter, Density: 1.5 to 1.6mt/m3.

can you please advice required buckets size, Pitch / spacing, Pulleys & drive HP to be required.

Thanking you all in advance.

Regards,

Pramit Patel ■

Unimaginative To Say The Least.

What is it with these questioners?

Power calculations were provided in previous replies on this very thread. Mr Mulani has given very comprehensive selection information well beyond the call of duty and still we get people searching for a free design without bothering to read and apply the information provided. We are, as often, casting pearls before swine.

If the previous questioner took the trouble to examine his own question he might note that he is heading for a dust cloud of unimaginable proportions and the substance of his question ignores that situation.

Unfortunately I am not able to attach the appropriate emoticon. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Worth A Try... ;-)

Hello John,

;-) it should be some pearls, or a glittering flag for a miracle engineering design request ;-)

Dear Mr. Patel,

I do normally avoid the word humble, but for the content and drive of your request I'd humbly step down. This job needs some professional to your side who first sorts out all the required input and then does the necessary design and calculation. You are surely aware that such services are not free of charge as a professional engineer would need to do & sign this.

If you request the job done on the net, you will perhaps get some answers, but without any warranty to the correctness or reliability. Also, pls. forgive me the frankness, it seems that you might not be able to assess the results. And, this finally robs some capable engineer in your vicinity of a job which should be his / hers by right.

Please reconsider your approach, or else explain better your intent.

Regards

R. ■

Bucket Elevator Motor Power Calculation

Hello

I need some information for bucket elevetor. Does anyone know the formula or the equation to calculate the necessary HP?

lazsalo ■