The drive of end-users towards efficient raw-material sourcing combined with the need for a feed material quality of even increased consistency leads to new challenges for material blending and homogenising. Centralised blending and homogenising facilities may be a solution to reduce the cost impact on the production process. The example of a coal handling system with the coal provided by road trucks from up to eight different mines with a wide variety of coal characteristics is used to discuss from a stockyard designer’s as well as an equipment supplier’s point of view the challenges related to the requirement of high product homogenisation.

Introduction

The example investigated in this paper relates to a recent project in South east Asia. The conclusions drawn, however, may be applicable also to projects in other parts of the world. with the growing demand of developing economies, new technological developments in the raw materials market such as the fast growing use of unconventional gas in the US, and the recent financial challenges to the world economy the raw material prices become more and more volatile. This, in combination with an underlying long term trend towards higher prices, leads increasingly to short-term supply contracts and opportunity driven sourcing (Fig. 2).

That does not only pose a challenge to the procurement department but also to operations. Raw material coming in with varying characteristics from frequently changing sources makes planning of efficient production processes more difficult, in particular looking at the high requirements of most modern production systems like boilers with more than 40 percent energy efficiency, blast furnaces or cement kilns just to name a view.

![Fig. 2: Production and consumption of energy resources per regions [6].](/sites/default/files/public/styles/basic_max/public/2023-01/bsh2012_06_02_Lieberwirth_02_img.jpg.webp)

The increased number of raw material sources and hence material qualities leads to growing space requirements and the need for more sophisticated stockyard technologies. This, in combination with a worldwide trend towards stricter regulations on emissions such as dust and noise calls for centralisation of blending and homogenising facilities as a way to avoid too steep cost rises as well.

Changing Requirements to Stockyards

In a logistics chain the primary logistical task of a stockyard is to buffer the material flow. The various modules of a transport chain, characterised by:

- different batch size (transport capacity),

- different transport sequence, and

- different common transport distance,

such as trucks, trains, river barges or large ocean vessels can be unlinked by stockyards buffering the material in between. Thus, the transport modules can operate fairly independently and waiting times are reduced.

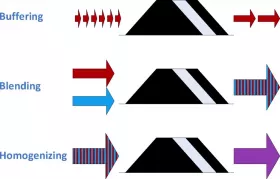

Further tasks of stockyards may be blending and homogenising of material (Fig. 3). At this point the difference between “blending” and “homogenising” should be reiterated, since until today the terms still are often used rather as synonyms. “Blending” is the process of mixing two or more different materials aiming at receiving a blend with a new average level of certain parameters. It is done for instance in ports if the material reclaimed from different piles is layered on a conveyor before feeding the material into the vessel. The layering is disturbed and the material is mixed at the conveyor transfer points. Usually, the total of the mix in the vessel then has a certain predicted average quality. The variation of the characteristics relative to the average over a period of time is often of lesser importance.

Mine stockyards often serve for blending of raw materials with sometimes widely varying characteristics originating for instance from various mining faces within one mine or from different mines within an area. The major focus here is on blending.

Selected parameters of the blend have to meet the specification in average and within a certain fluctuation range. The quality is regularly checked through sampling as per one of the internationally accepted standards.

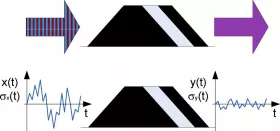

“Homogenising” defines the reduction of the variation of the parameters relative to the average, while the average is usually unchanged (Fig. 4).

Homogenising is often necessary to make the following production process more stable and efficient. It is therefore usually done at the end of a transport chain at a place next to the use of the material. Since it often requires re-handling it is costly and space consuming. So, space and equipment used for homogenising should be operated most efficient, if possible permanently round the clock.

The most economic point in the logistical chain is to be found for the investment. While for instance in the steel industry the steel grades produced change rather frequently, requiring a flexible raw material stockyard including homogenising next to the plant, in other industries like power generation the raw material quality is rather stable over the life span of a production unit. For these, it might be interesting to evaluate homogenised material from third parties or centralising of own facilities rather than investing in a number of local homogenising stockyards.

Adding Value with Stockyards – A Trend?

Be it in on the supplier’s side with the Indonesian Adaro coal group forming “Coaltrade Services International” to “handle the blending of Adaro Indonesia’s with other coals for value added purposes” [1], i.e. blending the low sulphur Adaro “Envirocoal” with other coals of inferior qualities to reap the benefits of providing coal with high blending efficiency as a supplier rather than leaving them to the end users. Be it on independent stockyards – often ports, such as EMO of Rotterdam – ideas are developed on blending and/or homogenising of materials to increase product quality and add value for the end users. On the contrary, on end user’s side discussions are going on to built centralised stockyards which feed several production lines with coal made to the specific need of each line rather than investing in a number of blending facilities next to each line.

Small Shipments with random Quality

South East Asia with its fast growing economies is an area where the above mentioned global challenges become particular obvious. In the Philippines, an electricity provider with plans to build a number of new power plants on various islands is investigating the option of a centralised coal blending and homogenising stockyard next to some smaller coal mines, which shall feed three plants, one next to the stockyard the other two at separate islands.

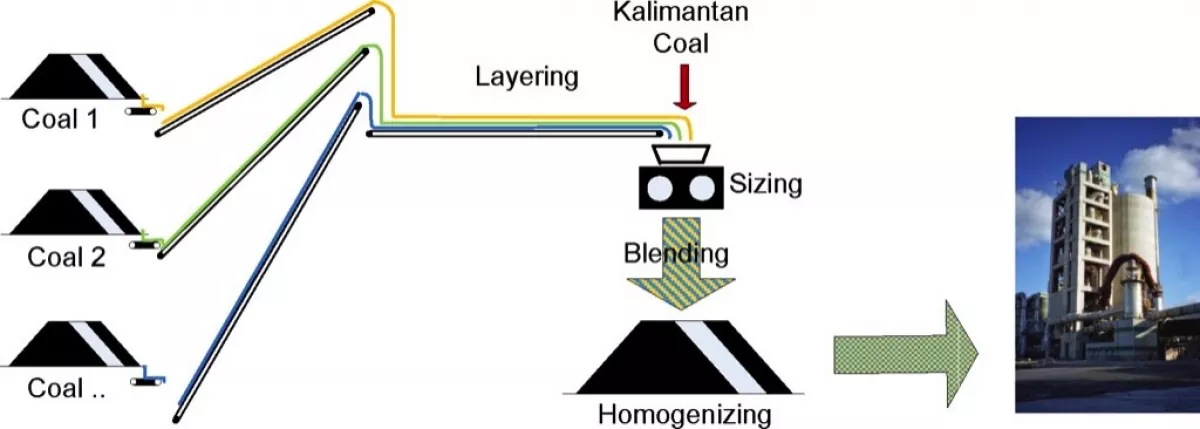

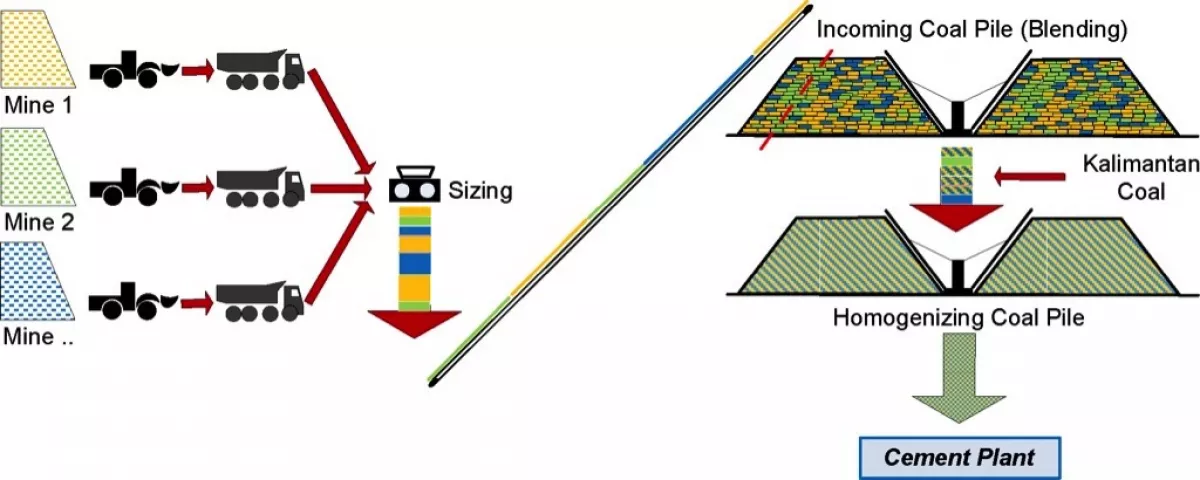

Yet, another specific case in South East Asia shall be taken as an example to discuss various topics related to the best blending/homogenising strategy in more detail. Presently, the operator of a cement plant with annual consumption of about 2 million tonnes of coal receives the coal from eight mines in the vicinity by road trucks and high quality coal by ship. The trucks come in random sequence from the mines. The material characteristics even of coal from the same mine varies substantially, since it is directly coming from the different mining faces. There is no coal blending next to the mine. High grade coal shipped from Kalimantan is finally blended with the coal from nearby in an attempt to achieve a stable coal quality (Fig. 5).

After weighing and sampling at the cement plant gate all trucks are directed to individual piles as per the source of the coal. The coal is dumped there and pushed to the piles. Wheel loaders take the coal from the individual piles as per the intended quality blend and dump it at the feeding point of the blending bed. High quality coal from Kalimantan is finally used to compensate for inferior qualities of coals from nearby. At the feeding point the coal is crushed and conveyed to the roof mounted tripper which builds up a Chevron pile. The coal is reclaimed via feeders and a tunnel mounted longitudinal belt conveyor. The blending pile feeds presently four different production lines. The client is looking for a more efficient coal handling system to supply the future five production lines featuring less costs on the stockyard as well as a more stable fuel quality.

Besides the high operation costs due to the immense labour intensity and the large number of mobile equipment employed, the homogenising capability of the existing systems does not meet the requirements of the modern cement production process any more. So, the plant operator is looking for a more efficient solution.

In the following consideration each truck is considered as an individual batch with certain characteristics. As per DIN 23006 main coal quality parameters of coal are:

- calorific value,

- ash content,

- sulphur content,

- water content,

- content of volatile maters,

- grain size distribution, and

- density.

Each batch is characterised by a certain average value and a volatility of those parameters. With large batches coming in from the various sources one would normally stack the material onto separate piles. With each batch being big enough for a number of layers over the full length of the pile desirable homogenisation within each material quality might be reached.

But with small batch sizes of about 20 tonnes even a small stacker, having a capacity of 200 tonnes per hour only, would not complete one single layer. Or the piles would have to be so short that the end cones with their adverse effects on the homogenising efficiency would make up for a major part of the total pile volume. Not to talk about change over times from one pile to the other in case of trucks always coming in from various resources.

A conveyor system, layering various material qualities onto the feeding conveyor to the homogenising stockpile would allow the blending of the various material qualities on the conveyor as per a predefined scheme (Fig. 6). The stockpile would serve merely for homogenising the material flow. Linking all the small individual stockpiles with a conveyor system, each feeder and conveyor having only a rather small throughput, would however generate prohibitive high investments costs for equipment and civil works.

The better alternative is to dump all incoming material from the local mines onto one of two large “incoming coal” piles (Fig. 7). While one of the two incoming coal piles is built up the coal from the second pile is reclaimed and fed to the homogenising piles. With all incoming batches being sampled, the average value of each characteristic data of the coal stored in the incoming coal stockpile is known.

Yet, the fluctuation of the values in time is unknown, irrespective of the method of stacking or reclaiming. In the worst case, a complete cross section of the incoming coal pile may be composed of just one type of material, causing very high fluctuation of the values (Fig. 8).

This fluctuation is widely compensated by the homogenising coal pile. While the average values of the data characterizing the incoming coal stockpile are identical to those of the homogenising stockpile the fluctuation of those data can be reduced dramatically.

The exact determination of the stockyard and stacking parameters, such as:

- stockpile cross section,

- stockpile length, and

- layer thickness (stacker speed versus stacking capacity),

is an optimisation process following mathematic rules described in the literature [2-4].

Equipment Selection

The best homogenising of material is reached by the operation of two longitudinal stockpiles each for the incoming coal and the homogenising task. A slightly cheaper option may be circular stockpiles (Fig. 9). With the virtually endless continuing stacking and reclaiming operation, one stockpile for incoming coal and one for the homogenising task are sufficient, saving investment in equipment, particular the stockpile conveyors, and saving space. The stockpile volume is limited, however, by the maximum possible diameter. A certain impact on the blending efficiency has to be considered as well. In particular, since the stacking process is limited to the Chevcon method with its adverse effects on the segregation of lumpy materials.

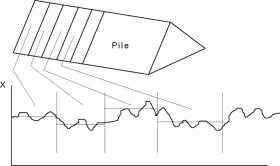

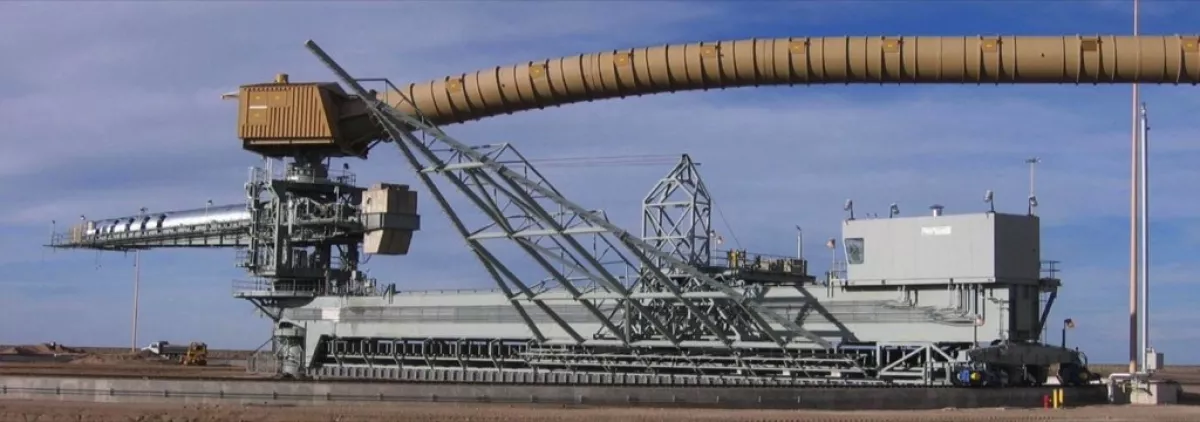

The selection of the optimum stacking method for longitudinal piles depends mainly on the material characteristics. Good blending and homogenising results require, however, that any cross section of the pile reclaimed contains at least 400 layers of material. Compared to proper stacking, reclaiming with its various methods has less influence on the homogenising of a material flow. The best homogenising effect is achieved while reclaiming at once from the full face. Respective machines would be: bridge type scraper reclaimer, and drum reclaimer (see Fig. 1).

Both machines scrape the material from the pile using full face harrows. Drum reclaimers are particularly suited for high capacity blending/homogenising of very abrasive materials like iron ore or materials which require a gentle handling like iron ore pellets. Application areas of both machines are shown in Table 1.

| Bridge type scraper reclaimer | Drum reclaimer | |

|---|---|---|

| Reclaim capacity [t/h] | < 2500 | < 6000 |

| Initial investment | Low | High |

| Suitability for abrasive material | Low | High |

| Energy consumption | High | Low |

| Gentle material handling | No | Yes |

| Constant material flow | Very constant | Slightly oscillating |

| Main application areas | Coal, Limestone, Additives | Iron Ore, Iron Ore Pellets, Coal |

Reclaimer, which remove only a fraction of the pile cross section at each point in time such as bucket wheel boom reclaimer, show a significantly lower homogenisation effect. Table. 1 shows a comparison between bucket wheel bridge reclaimer with one or more bucket wheels and a drum reclaimer.

Conclusion

Economic, technological and environmental considerations lead to increasing requirements for quality raw materials. Blending of raw materials has to be more and more complemented by homogenising. In many cases blending and homogenising cannot be done in one process step.

Additional stockyard facilities are often required. This will at least in certain industries potentially lead to a centralisation of the processing plants, offering new opportunities to large stockyard operators such as ports. The example of a cement plant in South East Asia shows, that the proper design of a stockyard and the selection of appropriate equipment, however, very much depend on the local situation, on size and quality of the incoming batches as well as on the requirements of the downstream production processes.

■