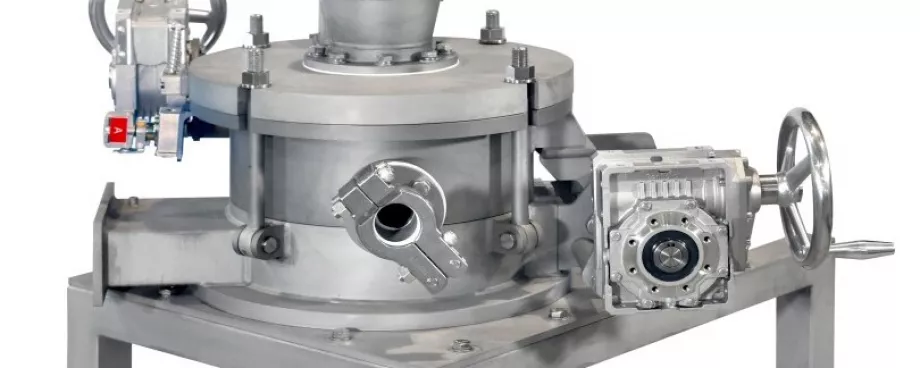

Kemutec’s Head of Applications and Proposals, Rob Dallow, explains: “The Easy-clean design allows thorough and verifiable cleaning of removable components like the rotor and classifier, plus full access to the internal surface of the milling chamber, which minimizes the possibility of cross-contamination.”

Designed for fast-paced Recipe Changes

The Easy-clean Mill provides unhindered access to the hard-to-reach areas where material residue can accumulate. This makes it particularly suited to trend-led and agile applications, such as powder paint processing, where colour changes require regular cleaning between batches.

Paint products’ sensitive colour recipes means cross-contamination has huge operational impact, potentially wasting entire batches and causing unplanned production halts. The PPS Easy-clean Mill’s optimized design offers a clear solution to these challenges, as Rob Dallow explains: “the ease of access enables major reductions in clean-down time between colour recipe changes, resulting in less downtime, more uptime and increased production capacity.”

Ideal for hygiene-focused Applications

The Easy-clean Air Classifier Mill also enables faster, safer more fluid production for hygiene-focused applications, like dairy processing. Here, key challenges include minimizing the health risks and avoiding recalls resulting from bacterial contamination in milk, casein and whey powders.

Like every Air Classifier Mill in the PPS range, the Easy-clean’s temperature-controlled operation can be calibrated to achieve the desired particle size distribution without degrading heat-sensitive food products. With the Easy-clean’s open design and simple to remove components - hygiene protocol can be strictly observed with efficiency, enabling better outcomes for product and productivity.

Custom solutions available

An acknowledged leader in the global processing industry, Kemutec is proud to offer its customers tailored solutions for their specific applications. In common with the rest of the PPS range, the Easy-clean Air Classifier Mill can be customized to fit a variety of physical layouts, process and material needs.

If you would like a first-hand or digital demonstration of the Easy-clean Air Classifier Mill’s capabilities, at Kemutec’s cutting-edge UK Technical Centre Laboratory, contact Kemutec.

To request information on the Easy-clean Mill, fill in the online form here.

About PPS Air Classifier Mills

Ideal for processing applications where grind size and temperature control are crucial, Kemutec’s PPS Air Classifier Mill range offers customizable solutions suitable for ultrafine powder grinding applications.

With a typical D50 particle size range of 5-10µ, the 11-model range is trusted by global customers in food, pet food and chemical industries, offering precision control over particle output and grind setting, with drive rates up to 250kw.

■