White Paper

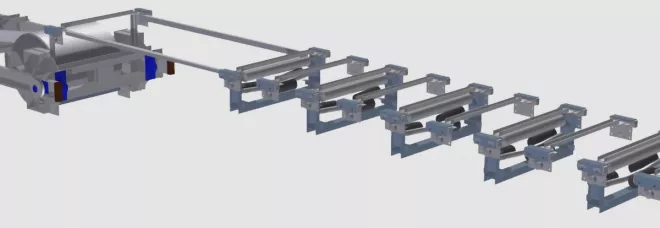

Pneumatic Ship Unloading Plants for Poorly Flowing Bulk Materials

The pneumatic discharge of free flowing materials has been realised for nearly a hundred years. The situation with respect to poorly flowing materials Is rather more difficult; until recently manual labour was used to loosen the product in the region of the suction nozzle. The author considers two l…read more