It might be a fruit farmer installing a belt scale on a large incline, a salt miner placing an idler too low under a conveyer belt or a cement producer not using a speed sensor.In each of these scenarios – and countless others – the purchasers of belt scales may be unaware that no matter how sophisticated and capable their scale is, if the location of the equipment isn’t carefully planned, the setup handled properly and numerous other extraneous factors taken into consideration, then the result can be inaccurate weight measurements.The experts at Siemens – with their decades of experience in the field – not only deliver superior belt scales, but also the know-how to make sure everything is installed properly so you can get the most out of your production equipment. In fact, even if you know you’re going to have an issue that might affect accuracy, they’ll be able to help quantify the extent of the impact so that it can be minimized.This article looks at 10 of the most common problems you might encounter, and some tips on what you can do so your production is not adversely affected by maintenance or downtime.

The Terminology: Accuracy, Repeatability and Linearity

Before looking at these issues, it’s important to first review the terminology involved, because often the word “accuracy” is used in weighing without really completely understanding it (Fig. 2).When a belt scale offers one correct measurement, then that measurement is considered accurate. In other words, if100 tons of material is transported on a conveyor and the scale reads 100 tons, then the accuracy is perfect. But this is just one single data point. Accuracy needs to be repeatable. You need accurate readings over and over and over again. So if 100 tons of material is transported every day for 10 days and the scale tells you 1000 tons have been moved, then that is perfect repeatability.

However, you still need even more than that. What if you have to adjust the load being weighed from its normal amount to a higher or lower weight? For example, your 100 tons per hour most of the time might only be 20 tons per hour on occasion. After such a “turn down,” you still need accuracy and repeatability. If you can achieve that, you now have linearity – the third leg of the measurement stool (Fig. 3).So keep in mind that problems can relate to accuracy, repeatability and linearity – or a combination of any of them.

Determining the Impact: Every Situation is different

You also need to remember there are limits to how precise any one impact can be quantified. Every application is different – and will yield different results.And most importantly, because a belt scale is part of a larger dynamic application involving lots of moving parts, several of the problems often occur at the same time. This makes estimating an exact impact extremely difficult. So in addressing the 10 problems outlined in this article, note that each estimated impact is based on an individual issue being looked at in isolation. In reality, it’s likely that multiple issues are involved.In addition, all the estimates provided are not based on empirical data. They come from the real-world experience of engineers and technicians of the author’s company. Even though that experience is extensive, any numbers provided should be viewed only as an approximate guide.

Problem #1: Inaccurate Input when setting up means inaccurate Output when measuring starts

There’s an old adage in computer science – garbage in, garbage out. It means the quality of an output is determined by the quality of an input. The integrator is your belt scale’s computer. If the information entered into it is not accurate, every measurement it produces will not be accurate.As a result, careful attention must be paid to critical parameters that are keyed into the integrator before any measurement takes place. This includes the spacing between idlers, belt length, the speed sensor’s pulley diameter and the mass of the weight being used for calibration. For example, if the space between idlers is off by five percent when that data point is entered into the integrator, accuracy will also be off by five percent. Or if the pulley diameter is off by five percent, then the accuracy will also be off by the same amount. The correlation is direct no matter what the parameter.

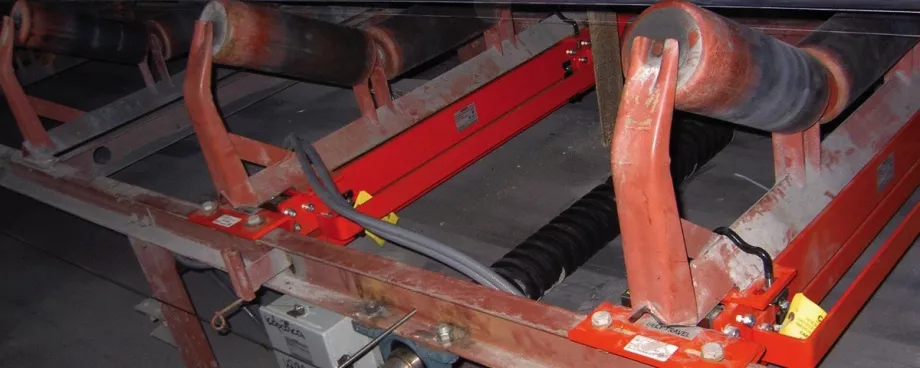

Problem #2: Idlers placed too high or too low – the most common and significant source of reduced accuracy

The single biggest problem with scale accuracy, repeatability and linearity is determining where the idler for the weighing device is to be located. It cannot be too high above the conveyer belt or too low beneath it. There is an optimum height adjustment for every conveyor belt. And it can involve a painstaking process to get that alignment just right, because if it is off from the ideal by as little as half a millimeter, it can result in a sizable negative impact.On the one hand, if a weigh idler is placed too low relative to the other idlers, a tight conveyer belt could “bridge” over the scale. Simply stated, it could pass over the scale completely undetected. The weight of the material on the conveyer at one point in time might not push it down far enough to even obtain a recording. More material might be added later, which will then push the belt down so that it comes into contact with the scale, but the results will be inconsistent, with the weight being measured only some of the time.On the other hand, if the weigh idler is too high, the opposite effect will take place. It can significantly increase belt tension, much like a rubber band being dramatically different when stretched compared to not stretched. As a result, a sizeable downward gravitational force could be exerted on the scale that exaggerates the weight, making it inaccurate on the heavy side.Belt scales from the author’s company are designed to be accurate within plus or minus 0.5 percent, with some very high accuracy systems guaranteed to have an accuracy of 0.25 percent. For those levels of accuracy to be obtained, weigh idlers for the regular scales must be within 0.8 millimeters of the optimum location, and within 0.4 millimeters for high-accuracy devices. An alignment out by as little as 1.5 millimeters can throw accuracy and repeatability off by as much as three percent. If it’s off by three millimeters, the impact could be as high as 10 percent. And if it’s six millimeters, it’s possible for inaccuracy to be as extreme as 30 percent.To put that into financial perspective, consider the case of a gravel producer operating a production facility with a capacity of 200 tons per hour. If the gravel costs USD80 per ton, an inaccuracy of just 0.25 percent would cost that company USD83 200 in lost material over the course of a year.

Problem #3: Belt tension too high or too low – a close second as a source of reduced accuracy

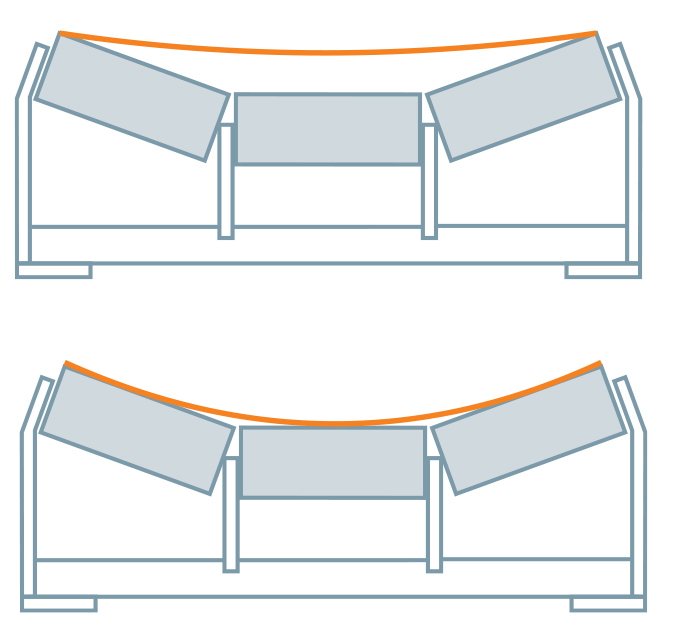

Right behind idler alignment – and closely related to it – is belt tension. If the belt tension is too high, bridging over the scale, as described in Problem #2, can become an issue. If the tension is too low, the material will shift as it rides over the “hump” of an idler. This can cause repeatability errors and material spillage.Even if the tension is set up correctly at the outset, the ongoing operation of a conveyer can lead to tightening or loosening through a range of factors – including temperature fluctuations, ineffective gravity tensioners, changes to the nature of the material being fed onto the conveyor, inclines that may vary along the belt path and erratic belt tracking.There needs to be an ideal belt tension, resulting in a “sag” of two percent between the idlers. The further away from two percent, the more inaccurate the weighing and the greater the number of non-repeatable results. Belt sag of less than one percent can alter accuracy and repeatability by as much as 10 percent. Belt sag of more than 2.5 percent has an impact of up to two percent. If the sag is greater than five percent, then there could be major issues that must be addressed.

Problem #4: Scale not installed in the proper location – especially if it’s too close to inclines or a vibration source

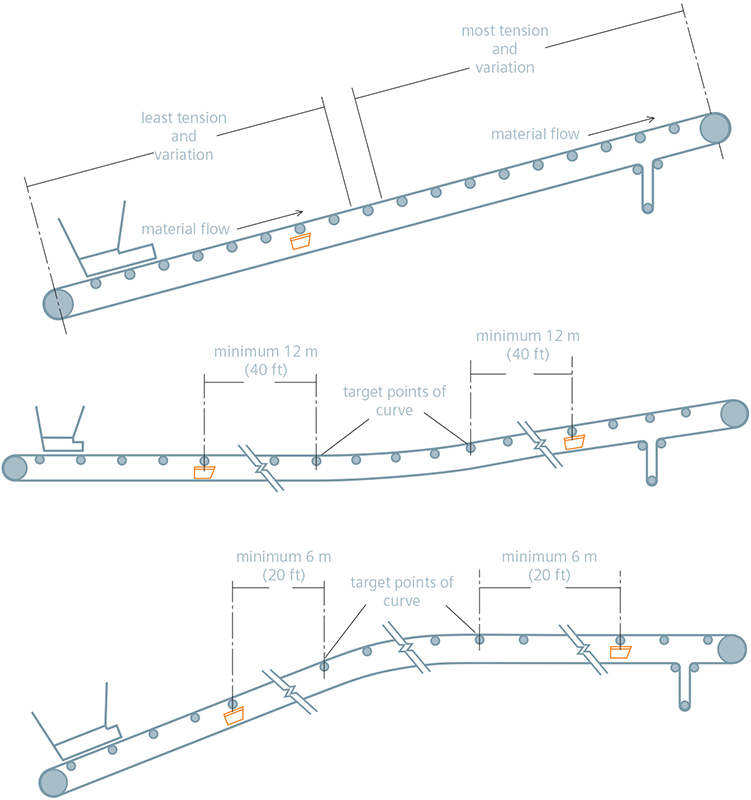

Choosing a sub-optimal location for the belt scale represents another leading source of reduced accuracy.For example, both convex and concave style conveyers can present significant challenges (Fig. 4). The belt scale should be placed at least 12 meters before or 12 meters after the tangent point of a curve. Consider an agricultural facility where apples are moved on a conveyer belt. If the scale is too close to the incline, some apples could pass over the scale, and then roll back down the incline and be measured again, making the reading inaccurate. The impact on accuracy and repeatability in this circumstance could be as great as 30 percent.

A variable-incline conveyer, going from flat up to an inclination of 16° will negatively impact accuracy by four percent. In general, inclines of just 20° can create roll back, and if the incline is 40° or more, the impact on accuracy can be so significant that it cannot even be predicted.To address conveyer inclines and prevent roll back, some belts have integrated ridges to provide additional material traction. But those parts of the belt with these ridges will not behave in the same manner as the rest of the belt (in particular, not enabling a proper “trough” position that is needed for measuring), which can also limit accuracy.Vibration is another key issue to consider when selecting where to locate the scale. For instance, in the aggregate business, mobile crushers that can generate a lot of vibration are used. If the proper scale design is not used, they can cause the load cells to move up and down, creating erroneous outputs of up to two percent. Generally, there is no need for concern if vibration is not actually visible. However, if it is visible, accuracy and repeatability can be affected. In fact, in rare, extreme cases of vibration, a scale could fail. Mounting a scale close to a support structure can be a good way of combating the effects of vibration.Other installation locations to avoid include those that are:

- too near transition idlers that change the profile of the belt, leading to a change of as much as 15 percent in accuracy and repeatability;

- under skirt boards or seal strips where material can “pinch” into the belt at the scale idler, which might mean a change of as high as 10 percent;

- near a winged pulley, as the pulley can wrap around the conveyer belt, “whipping” it off the scale, which can have an impact as high as 10 percent; and

- close to metal detectors, which can negatively influence accuracy by up to five percent.

To avoid these problems, installation guidelines should be carefully followed.

Problem #5: Poor conveyer quality or incompatible conveyer design

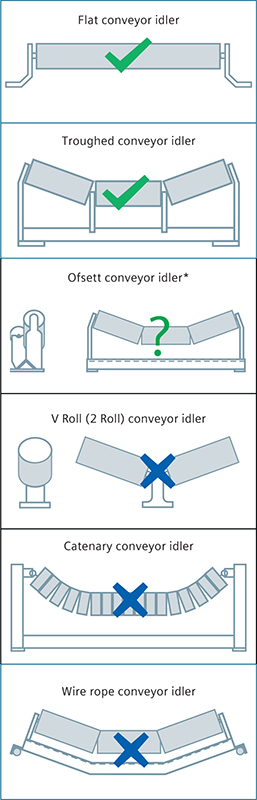

The quality of conveyers and their components can significantly influence accuracy.A frame that is improperly designed or has deteriorated over time may not adequately support the weight of the material, thus causing the conveyer to twist. This could negatively impact accuracy and repeatability by up to 20 percent. Another issue is that idlers could be worn out or do not rotate smoothly. These effects can create friction, leading to vibration, which in turn can mean measurement inaccuracies of up to 10 percent.Faulty tensioners are another common source of concern, because they are incapable of serving their intended purpose of compensating for loads on the conveyor belt or temperature changes. And of course, the belt itself is also a key factor. It could have poor splicing, holes or tears, resulting in lost material and therefore inaccurate measurements.There are also conveyers that may be brand new, but they can be even more problematic than older, poor quality ones. This is because their design may not be suited to housing a belt scale. If they are equipped with flat or troughed idlers, they should work well. But v-roll, catenary and wire rope idlers will simply not be compatible.In the case of the wire ropes, even though the idlers may be rigid, as soon as the conveyer begins to move, all of the measuring equipment will also move due to the inherent rope design (Fig. 5).

The type of belt used is also a factor. Some customers choose belts that are over engineered for their needs, most typically a belt that is too thick or with a core of steel. In these cases, the belt might not flex enough to give the sag needed to establish contact with the scale (Fig. 6)

Problem #6: Thinking you don’t need a speed sensor

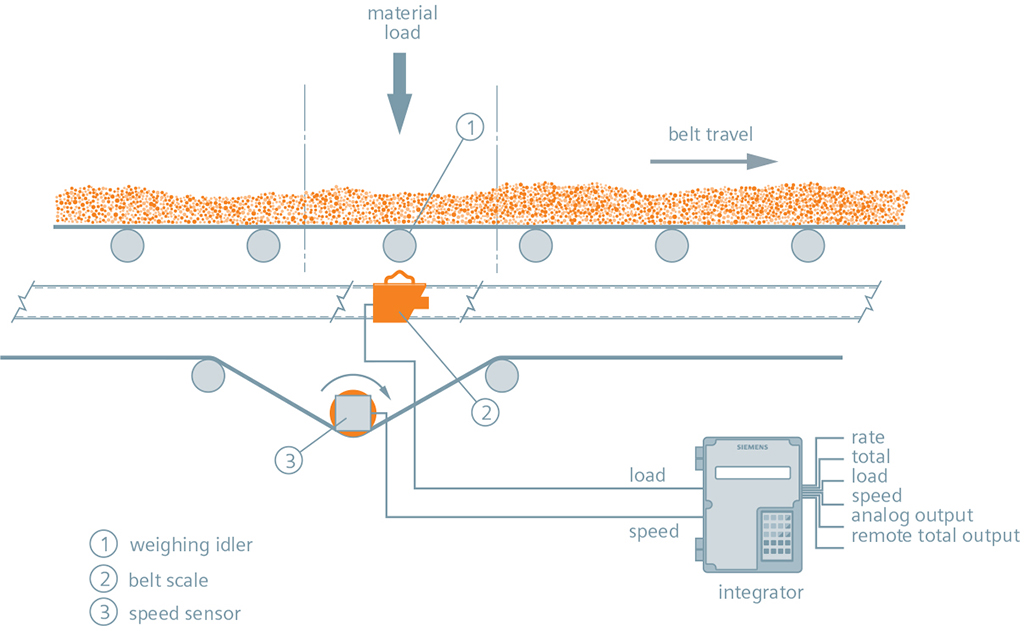

In a dynamic weighing environment, speed monitoring is just as important as load sensing. It demands the same care and attention, and utilizing a speed sensor gives you the peace of mind you need to ensure that part of the weighing equation is covered (Fig. 7).

It’s common to hear some operating companies state that their conveyers run at a constant speed, so there’s no need for a speed sensor. Unfortunately, no conveyer actually runs at one uniform speed. There is always some variation. For example, at a rock quarry, a site manager might have a conveyer running at 100 feet per minute (approx. 0.51 m/s). The assumption is that it’s always running at that speed. But when the conveyer is tested, it generally is off a little, running at a speed, for example, closer to 102 feet per minute (approx. 0.52 m/s). That two percent difference directly translates into an accuracy that is also off by two percent.

Problem #7: Belt speed too fast and/or material not on load scale for long enough

Materials can begin to “bounce” off the conveyer if it’s moving too quickly. If measuring takes place during the period of time when material is in the air, that weight will not be measured. In addition, when the material lands, it will create turbulence, which can also affect the accuracy at the time that the measurement is made.Belt speeds greater than 6 m/s (1180 ft per minute) can create inaccuracy of one to five percent, which can be an issue if high accuracy is required.Consistent material profiling can help mitigate the impact of this issue if the bouncing effect is repeatable. However, other factors would also need to be kept consistent at the same time, including moisture content, bulk density and particle size.Similarly, whether it’s from bouncing or another reason, it’s important that the material being weighed is on the scale itself for a sufficiently long period of time so that its weight can be accurately recorded. Load cells are essentially springs. There needs to be adequate “retention time” for changes in forces to settle on that spring, and the weight to be captured and transferred, before the material is moved from the scale area. This multi-step process cannot take place with the appropriate precision if the material moves too quickly over scale.As a general rule, the specified product data can be achieved if the retention time is greater than 0.4 seconds. If it is 0.25 to 0.4 seconds, there can be a 0.5 to two percent impact on accuracy and repeatability. The impact can be between one and five percent if the retention time is less than 0.25 seconds.

Problem #8: Dynamic frequency ratio causing resonance effects

In 1940, one of the most famous engineering failures in history was captured on film when the Tacoma Narrows Bridge collapsed, twisting itself and ripping apart spectacularly because of a resonance effect where its natural frequency was excited in heavy wind conditions.For a belt scale, a similar effect occurs with the device’s “dynamic frequency.” Scale oscillation creates a resonance effect, and this must be taken into consideration. In the weighing system, there is a natural frequency associated with the force that the belt exerts on the weigh idler, as everything is supported on two load sensors. Loading, spacing between idlers and the speed of the conveyer can potentially work together to induce enough oscillation to match the natural frequency of the load cells. If this happens, the whole arrangement could become unstable. At that point, it becomes not just a matter of reliability but safety as well.To ensure this does not occur, you need belt scale experts to perform some complex mathematical analysis and determine your scale’s “dynamic frequency ratio.” The idler, belt loading and belt speed are on one side of the ratio, while load cell detection is on the other side.If this ratio is one, the load cells will fail, just like the bridge collapsing. In fact, any value above 0.3 could represent a problem and impact accuracy by up to 10 percent. When the Siemens weighing team encounters anything above 0.3 they will engineer a solution to reduce the number down to 0.2 or lower, where the impact is minimal.

Problem #9: Load cell signal too low

If we use our cell phone without any interference, we tend to enjoy great signal quality, and the little icon on our device will verify this with five bars in the top corner of the screen. If there is lots of interference, the signal can be really weak – with just one bar on the signal strength indicator – and we might strain to have a decent conversation.There’s an analogous situation for belt scales involving the signal from their load cell to the integrator. Each load cell needs a clear “resolution” in which detailed weighing information about the material being conveyed is captured, while any non-material weight (such as the weight of the belt scale itself or the idler) is able to be dismissed as being irrelevant. Consider an aluminum can recycling operation. Each can is very light so that the weighing system must have a high resolution, because an influence such as a belt tension change could have an impact greater than the actual weight of some cans.The guideline is to use at least 30 percent of the entire load cell capacity to prevent other influencing factors from having a disproportionately large impact on the scale’s performance. Accordingly, a live load signal indicates the output range that the load cell can generate based on material loading. If that signal is less than 2 mV – reflecting a low resolution – there could be a one to five percent change on accuracy and repeatability. If it’s 2-3 mV, the impact can be 0.5 to two percent. Product resolution specifications can be attained at greater than 3 mV (using a 2mV/V-style load cell).

Problem #10: Calibration not performed frequently enough – or calibration method is incorrect

When a scale is installed, a “zero calibration” is performed to determine the weights and forces of everything other than the material being weighed. For example, if no belt-related weight is recorded when doing the initial calibration, then this weight will not be subtracted when actual measurements are made.That initial calibration might be perfect. But the dynamics can change significantly – whether an hour, a day, a month or several months later – as a result of a variety of factors, such as material building up, the onset of conveyer belt issues or environmental changes. This means that you will need to recalibrate your scale at specific intervals to ensure accuracy, repeatability and linearity. You may have to calibrate your system twice a day if it involves a high-accuracy scale or a critical application. Once a week tends to be sufficient for most applications. Some might find once a month is acceptable for their particular situation. The key is to have performed enough calibrations in order to establish a clear predictability pattern.Each case must be looked at individually. Let us consider temperature to illustrate this point. Belts at outdoor sites need to take different temperature conditions into account. A belt running early in the morning will have different properties than later in the day. In the morning, there might be extra weight from condensation that will dry off later on in the day. And rubber typically seen in belts will be less stiff in the afternoon after it has been running for a while with warmer temperatures and the sun shining on it. (Before any belt scale is calibrated, the conveyor should be warmed up for about half an hour.) Similarly, seasonal temperature changes will have an impact, as a belt in the summer will have much different characteristics than a belt in the winter. Repeatability might be affected if the system is not calibrated at various times to take these types of fluctuations into account.Extreme temperatures can be especially tricky. Belt scales from Siemens, for example, can be operated from -50°C all the way up to +60°C. But there are occasional circumstances – such as a mine in the far north – where it might get colder than that. In applications such as these, in addition to carefully calibrating the system to take into account these extremes, the installation may have to be modified to protect the integrator from cold.In addition to frequency, the method used for calibration is also an important consideration. You need to make sure you are choosing the right solution for your particular application. Using the actual material being conveyed for verifying calibration is the best method to ensure that the scale can achieve the highest possible accuracy.If this is not possible, using test chains (representing 40-60 percent of the load) is the next best option to achieve optimum accuracy because these most closely simulate material flow on a belt. Static test weights (representing 25 to 40 percent of load) can be used, but will not be as effective as chains because all the dynamic forces of material in motion will not be captured. Typically, chains should be used for critical applications or those demanding a high accuracy. Weights are more acceptable for less accurate applications.A third choice is electronic calibration, which does not involve physically using weights or chains. This is only acceptable for applications where just a very low accuracy is required.As a general rule, electronic calibration results in a one to five percent impact on accuracy, weights, 0.5 to five percent and chains, 0.5 to two percent.

Make sure you choose the right scale from the right manufacturer

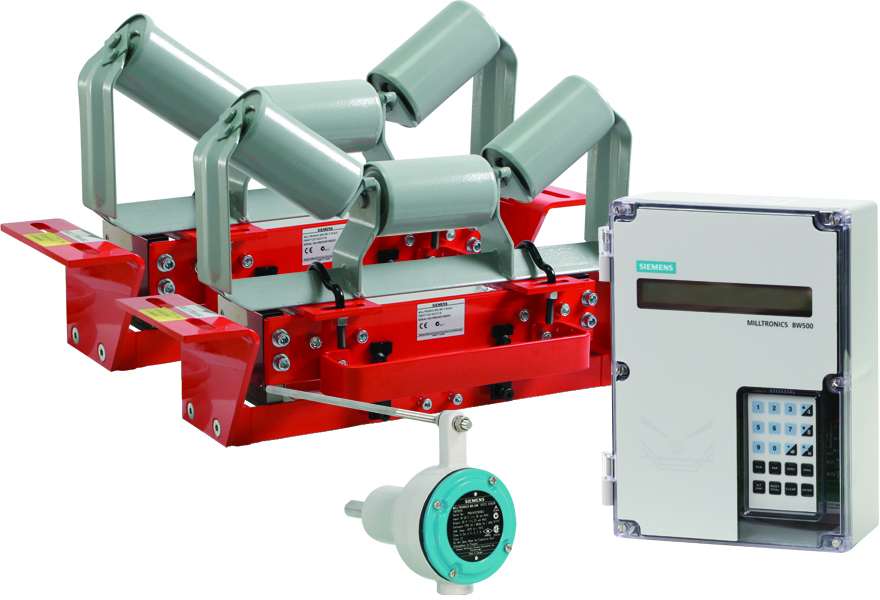

After you have understood and managed all of these 10 problems, you still need to make sure you have a high-quality belt scale. Once again Siemens experts can also provide support here, as they have been offering technically advanced belt scales for a long time now.

Siemens systems feature the simplest mounting and lowest maintenance requirements on the market. They have no moving parts, are equipped with corrosion-resistant load cells, and are designed for 300 percent of ultimate load cell capacity. Together with Siemens high-resolution speed sensors, you can achieve high measuring accuracy,repeatability and linearity.Not all scales are created equal. Just consider the maintenance issues if you are looking at a model with bearings, leaf springs, pivots, bushings, counter balances or check rods. These mechanisms require much more attention in order that they operate correctly, and they also have slower reaction times to changes in load levels as well as hysteresis as a result of temperature and long term wear.Best of all, everything sold comes backed by the knowledge and experience of a team of leading industry experts who are always available to help you.

| About the Authors | |

| Matt MorrisseyProduct Manager, Weighing TechnologySiemens AG, Canada |

■