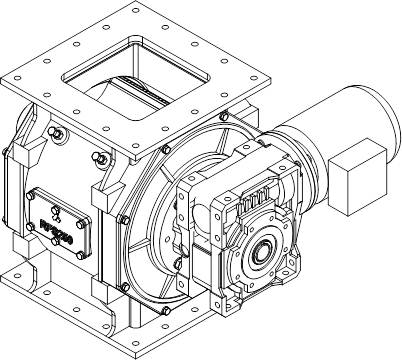

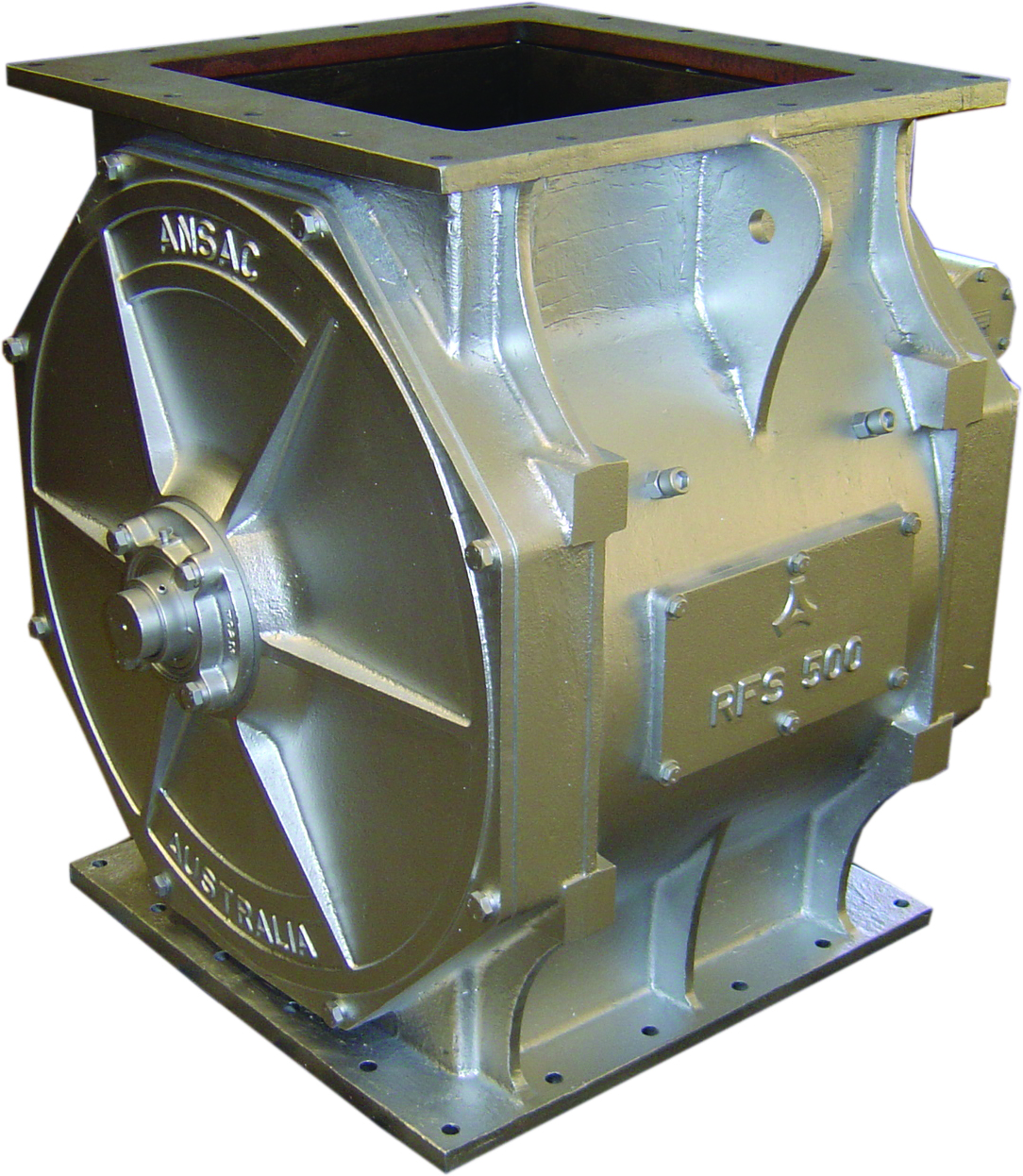

Anval Rfs Series Rotary Valves

RFS SERIES - ROTARY VALVES

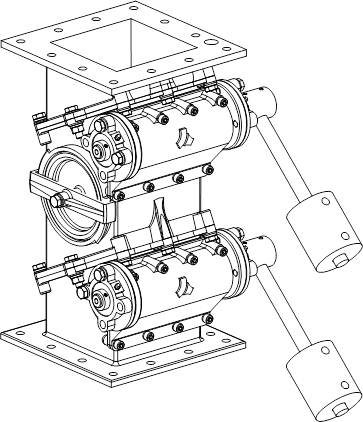

RFS Rotary Floating Shoe valves provide unmatched performance as airlocks in high wearing applications. This RFS series can last up to four times longer than traditional rotary valves.

THE TOUGHEST AIRLOCK OR METERING SOLUTION FOR HIGH WEARING PRODUCTS

Rotary Floating Shoe or RFS Valves form an important part of the Anval range of materials handling valves. RFS Valves are rotary valves specifically designed for high wear applications.

The valves can be used in both positive and negative pressure applications and consist of a main body with bolt-on side plates and a rotating, webbed rotor located in between.

Opening Size: 250 to 750 mm

Flange Opening: Circular / Square

Temperature: Upto 200° C

Drives: Direct Driven / Chain Driven

Material of Construction: Mild Steel / Cast Iron / Stainless Steel

Capacity Range: upto 550 m/hr Max.

Technology

To achieve 100% positive sealing, the Anval RFS Series Valve has a "FLOATING SHOE"' which slides tightly into the main body top port flange and rides onto the rotor by gravity force. The shoe slide is sealed with a double 'O' ring between the shoe and the main body, and where the shoe rides on the rotor, the contact surface between the two parts forms a mechanical seal.

Features

The Anval RFS Series also feature a sacrificial, hardened SG iron adjustable shoe. The shoe, which sits on the rotor, has up to 10mm of wear and can be adjusted externally while in operation to maintain minimal clearance at all times.

•Ultra heavy duty cast iron.

•Ceramic tipped rotor to ceramic tipped rotor to improve wear.

•Adjustable hardened cast iron shoe to maintain airlock even after some wear has occured.

•Available in direct drive or chain drive.

•Easy to maintain.

•Up to 200°c product temperature.

•Heavy duty cast iron construction

•Available in a range of speeds

Long Service Life

The long service life that distinguishes Anval RFS valves from all other valves in the market is achieved through the ceramic tips embedded in all leading surfaces of the blades and end plates of the rotor.

Applications

Anval Rotary Floating Shoe Series Valve offers up to 4 times the life of a standard Rotary valve offering unparalleled value for high wearing products such as Alumina, iron ore, cement, coal, fly-ash and mineral sands.

RFS series valves are designed to require very little maintenance over their service life. Anval can offer an overhaul service for customers in which out of service RFS valves can be returned and re-conditioned for return to the client. This minimises the spare parts inventory required by the customer as well as the on-site training required. For customers who rather carry out their own maintenance Anval stocks a comprehensive range of spares available for quick turnaround.

For more information, please visit:

https://edir.bulk-online.com/oldedir...ves-209581.htm

https://edir.bulk-online.com/oldedirredirect/209950.htm ■

Anval Bh Series Blow Through Valves

BH SERIES - ROTARY BLOW THROUGH VALVES

High efficiency blow thru Valves, for handling food, flour, grains, plastic, chemical, pharma and milling industries. This “Single piece” cast design can handle a maximum capacity of 83 m/hr with a maximum operating temperature of about 100°C.

HIGH EFFICIENCY BLOW THROUGH VALVE

Anval has an extensive range of rotary valves used in a wide range of applications from heavy minerals industries to light agricultural applications.

Anval ranges of BH valves are available in opening sizes from 150, 200,250, 300 and 350 mm. BH series rotor is fabricated open-ended style, perfectly designed and manufactured to have a close radial clearance of 0.10mm.

Anval BH series body is fully cast on a single piece reducing the number of seams for wear. These valves are compact in design and robustly built.

Opening Size : 150, 200, 250, 300 and 350 mm

Flange Opening: Square

Temperature: Upto 100° C

Drives: Chain Driven / Bare Shaft

Material of Construction: Cast Iron

Capacity Range: Upto 83 m/hr Max.

Rotor : Open Fabricated type

Features

•Heavy Duty cast iron construction with Chain drive.

•Robust body and compact in design.

•Easy installation and maintenance.

•Upto 100 ºC product temperature.

• Reliable solution for smooth conveyance of materials in a

pneumatic conveying system with minimal leakage.

Applications

Anval BH Series valves are best suitable for food, flour, grain, plastic, chemical, pharma and milling industries. Ulike our competitors, these valves are uniquely designed for the pneumatic conveying systems to achieve a smoother flow of materials.

Suitable for non-abrasive products and can eliminate pressure drop to very minimal.

For more information, please visit:

https://edir.bulk-online.com/oldedir...ves-209581.htm

https://edir.bulk-online.com/oldedirredirect/209950.htm ■

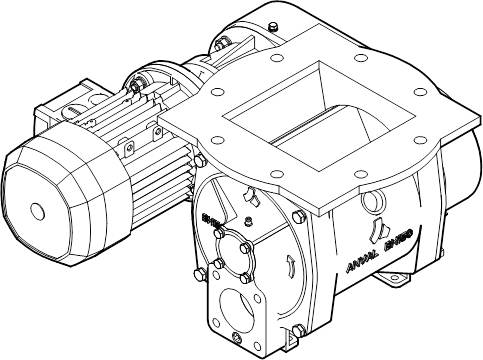

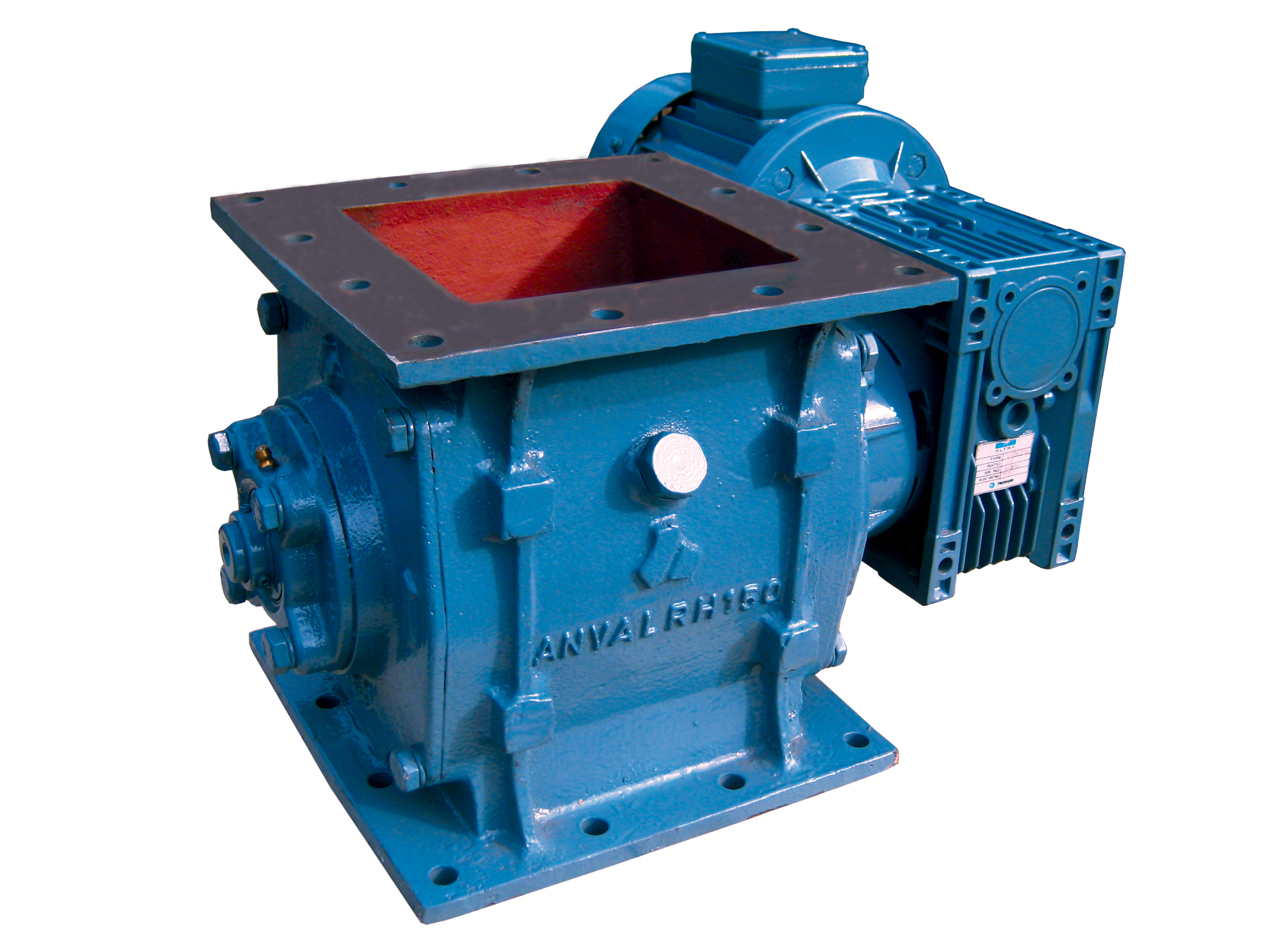

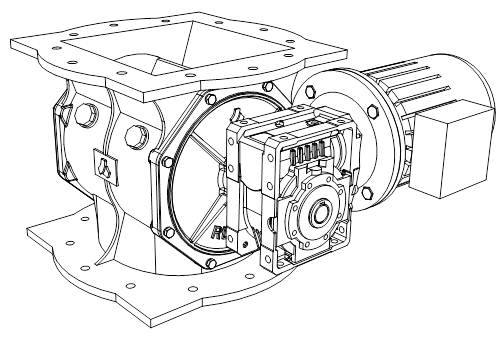

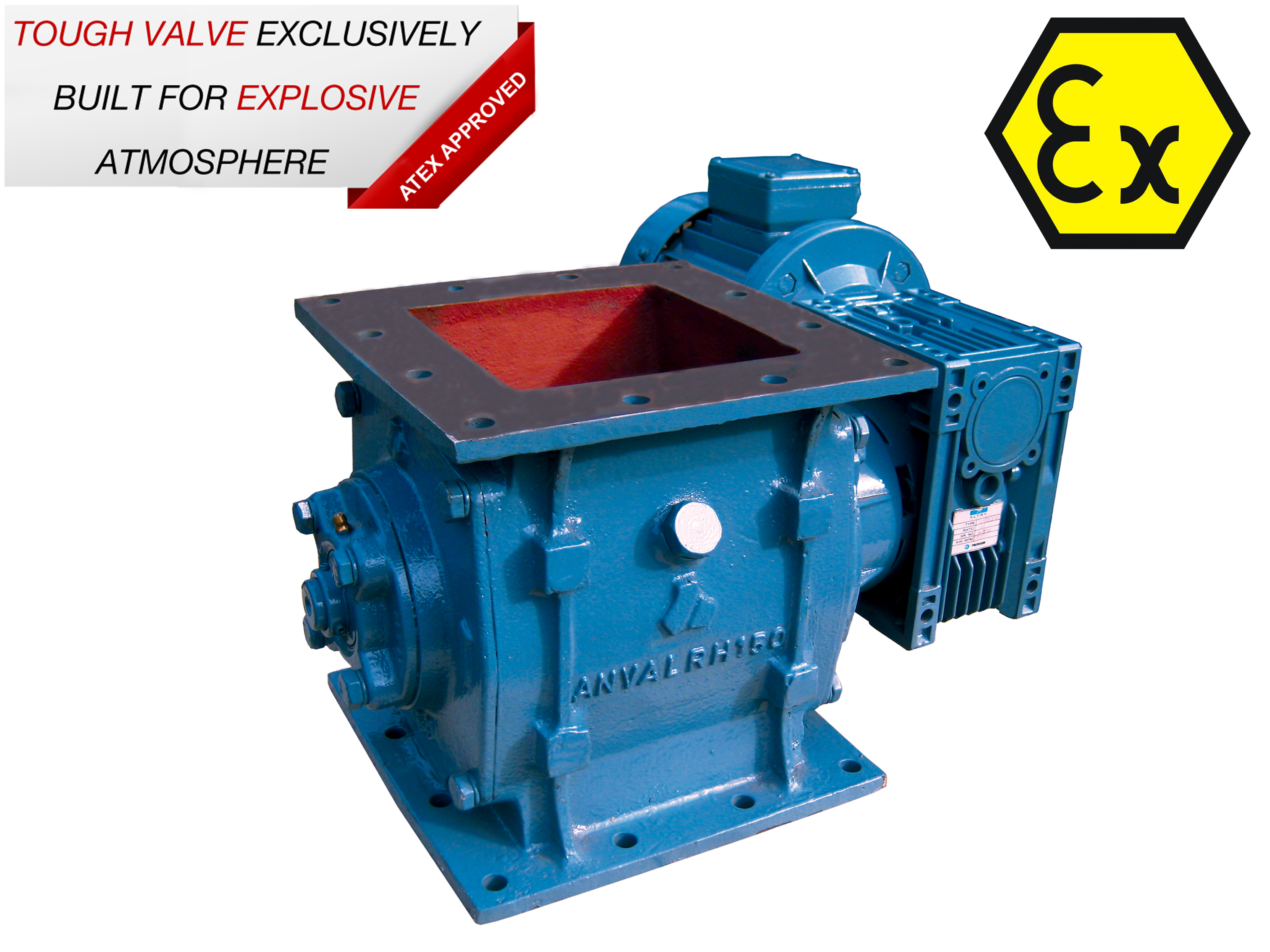

Anval Rh Series Rotary Valves

RH SERIES - ROTARY VALVES

Robust, high efficiency and versatile design, all for handling bulk materials with various properties and applications. This “Single piece” cast design can handle a maximum capacity of 215 m/hr with a maximum operating temperature of about 200°C.

ROBUST HIGH EFFICIENCY VERSATILE DESIGN

Anval RH series rotary valves can serve to extensive range of applications from heavy minerals industries to light agricultural applications, even under harsh operating conditions.

Our products and solutions have proven themselves across a wide range of industries and in some of the most demanding manufacturing environments. We are proud to be the prescribed suppliers of valves for some of the world’s biggest mining companies.

RH series valves are available in opening sizes from 150mm - 600mm. Unlike our competitors, the Anval valve bodies are fully cast in a single piece reducing the number of seams for wear. In addition, as all of the components are manufactured from cast iron the valve has all of the advantages of cast iron over traditional mild steel including superior corrosion resistance, better wear properties and thermal stability.

Opening Size : 150 to 600 mm

Flange Opening: Circular / Square

Temperature: Upto 200° C

Drives: Chain Driven / Direct Driven

Material of Construction: Mild Steel / Cast Iron / Stainless Steel

Capacity Range: Upto 215 m/hr Max.

Anval RH Series valves can also be fully customised to suit your needs and can be fabricated with a range of sizes, materials and rotor configurations. RH series valves are available to be fabricated in mild steel, stainless steel and high temp alloys; regardless of the application required.

Features

•Specials manufactured to suit specific requirements.

•Direct mounted gearbox.

•Easy to maintain.

•Upto 200 ºC product temperature.

•Replacable "Labyrinth seals".

•Manufactured to suit specific requirements.

•Heavy duty cast iron construction

•Available in a range of speeds

Sealing Method

Perfect sealing is definitely required on the rotating shaft and Anval rotary airlocks adhere to it by using "labyrinth seals". To seal dust and achieve smooth operation, dust tight seal on a rotating shaft is required. These labyrinth seals even effective with highly abrasive products and also when there is a differential pressure.

Applications

Anval RH Series valves can be fully customised and can be fabricated to suit applications, thus allowing customers to choose product of their choice. RH series valves are best suitable for industries ranging from chemicals, food, steel, cement, wood, steel, power to mineral processing plants.

For more information, please visit:

https://edir.bulk-online.com/oldedir...ves-209581.htm

https://edir.bulk-online.com/oldedirredirect/209950.htm ■

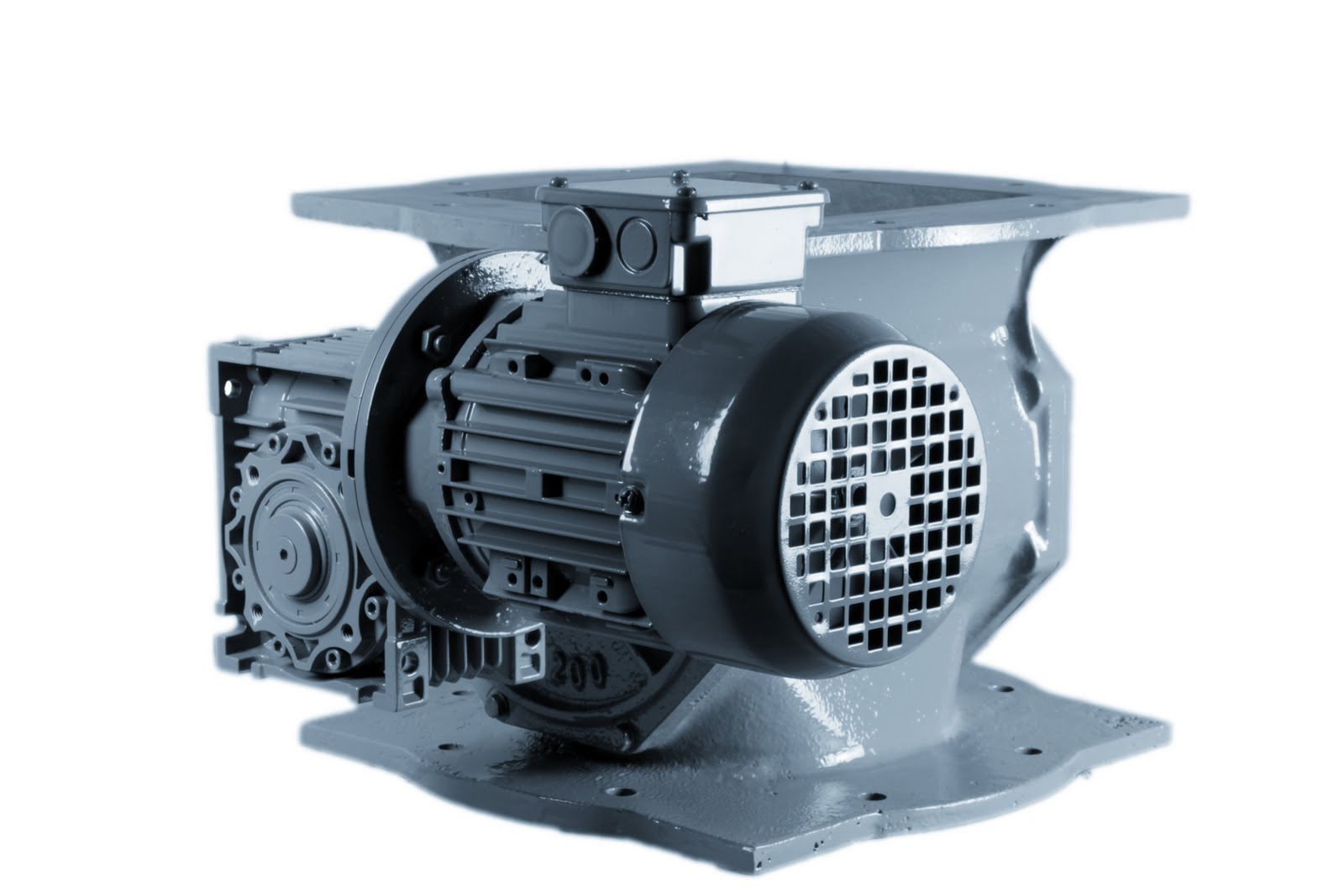

Anval Rl Series Rotary Valves

RL SERIES - ROTARY VALVES

Simple, stable and economical, is all we need to construct a reliable off the shelf airlocks. This "single piece" cast design can handle maximum capacity of about 33.6m/hr up to a maximum temperature of 200°C and can be used at various industrial applications.

SIMPLE STABLE AND ECONOMICAL AIRLOCKS

Anval has an extensive range of feeders & airlocks used in a wide range of applications from heavy minerals industries to light agricultural applications.

The RL ranges of valves are available in opening sizes from 150mm - 300mm. The simplicity of the Anval designs means a relatively low maintenance requirement and ready to use product.

Opening Size : 150 to 300 mm

Flange Opening: Circular / Square

Temperature: Upto 200° C

Drives: Direct Driven / Chain Driven

Material of Construction: Cast Iron - IS210, SG260

Capacity Range: 33.6 m/hr Max

Features

•Robust design

•High performance drive

•No difficult adjustments

•Minimum maintenance

•Heavy duty sealing arrangements

•Available in Direct / Chain drive types

•Excellent Airlock performance

•Cost effective

•Universal square flange

Applications

Rotary air lock valves have applications in the solid gas separation applications or solids metering applications. RL series valves are ideally suited for air locks on dust collection systems or solids feeding applications and can service a very wide range of industries and applications.

For more information, please visit:

https://edir.bulk-online.com/oldedirredirect/209950.htm ■

Re: Anval Valves

Differential Pressure: Upto 40 kPa

and

Differential Pressure : Upto 10 kPa

I might be wrong, but 0.4 to 0.1 bar does not seem much.

1 kPa = 1000 Pa = 1000 N/m2 = 0.1 N/cm2 = 0.01 kgf/cm2 = 0.01 bar

hence

40 kPa = 0.4 bar

and

10 kPa = 0.1 bar

The valves can be used in both positive and negative pressure applications

The pressure differences in these applications are normally much higher than 0.1 to 0.4 bar.

Have a nice day

Teus ■

Teus

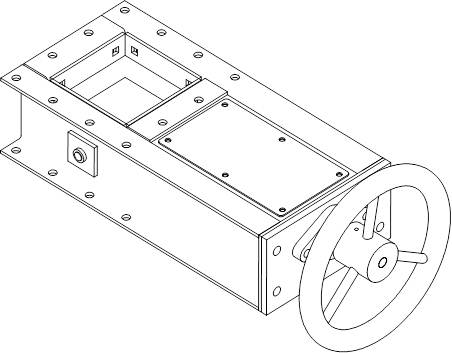

Anval Sl Series

SL SERIES - SLIDE GATE VALVES

Anval Slide Gate Valve Series was designed to provide a quick acting isolation unit that can be installed into a bulk handling flow path to stop material flow.

ECONOMICAL SIMPLE & ROBUST ISOLATION FOR SOLID APPLICATIONS

The Anval Slide Gate Valve Series was designed to provide a quick acting isolation valve unit that can be installed into a bulk handling flow path to stop material flow.

Anval slide gate valves are simple and compact in design, robust in structure, excellence in technology and are easy to install.

Slide gate valves are designed to shut off product flow from outlets of storage bins, silos, conveyors, and other discharge points handling dry bulk materials.

Anval SL Slide gate Valve series is excellent for industries and applications where the isolation of solids is needed. This is achieved through the forcing of the blade into the valve seat by the cam rollers. Pressure tight support frame assures the free flow of material without clogging and with minimal leakage.

Opening Size : 150 - 300 mm

Flange Opening: Square

Temperature: Upto 350° C

Material of Construction: Fabricated MS / SS

Actuators : Manual / Pneumatic

Features

•Economical and reliable solution for bulk material Isolation.

•Compact simple and robust design..

•Fabricated construction available in MS and SS Materials.

•Manual and Pneumatic actuation.

•Upto 350 C product temperature

•Pressure tight support frame.

•Minimal leakage and free flow of materials without clogging.

•Easy to install and maintain

•Heavy duty isolation.

•Designed and manufactured to meet international standard.

•ANVAL TRIGGER LOCK TECHNOLOGY for better sealing requirements

Applications

The Anval SL Slidegate Valve Series is excellent for industries and applications where the isolation of solids is needed.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

Anval Sg Series Slide Gate

SG SERIES - SLIDE GATE VALVES

Anval Slide Gate valves are designed for industrial bulk handling applications to provide a quick acting isolation valve unit to stop material flow when and wherever required.

ABSOLUTE ISOLATION FOR SOLID APPLICATION

The Anval Slide Gate Valve Series is excellent for industries and applications where the isolation of solids is needed. This is achieved through the forcing of the blade into the valve seat by the cam rollers.

The Anval SG Slide Gate Valve Series has been designed to meet Australian Standards and specifically AS1830, AS4024 and AS3679- 250 as well as to Anval’s high internal design standards.

Anval slide gate vales are simple and compact in design, robust in structure, excellence in technology and are easy to install.

Features

•Heavy duty isolation.

•Fabricated construction in a number of materials.

•Manual / Pneumatic or Motorized actuation.

•Compact and robust design.

•Upto 350 C product temperature

•Deal with pressure drops

•“Anval trigger lock technology” for better sealing.

•Easy to maintain.

•Custom valves to suit specific requirements.

Sealing Method

SG Series incorporates "Anval trigger lock technology" brings improved sealing, and has been tested above 350°C.

Applications

These valves are designed to handle bulk materials for all industrial applications, both continuous and intermediate operation.

href="https://forum.bulk-online.com/attachment.php?attachmentid=34169&d=1347972985" id="attachment34169" rel="Lightbox76035" target="blank">■

Anval Dh Series

DH SERIES - DUMP VALVES

Low cost versatile air locking valves available in single dump, double dump, gravity fed, motorised or pneumatic.

LOW COST, HIGHLY EFFECTIVE AIRLOCK IN VACCUM OR PRESSURE CONDITIONS

The Anval DH Series has been developed to provide industry with a low cost versatile air locking valve solution to discharge bulk solids while restricting the back flow of air, which can be used in either vacuum or pressurized conditions.

Double dump valve works with two flaps assembled in a housing continually operating in an alternative fashion, while flap one is closed to collect the material and the second one is open to discharge the material.

Anval DH series dump valve range is designed in a highly effective manner emphasizing on total sealing, continuous uninterrupted discharge, with long life and minimal maintenance.

The principle of operation of dump valves is based on flap assembly continually alternating in operation, with one closed and collecting material while the other is open and discharging material.

Features

•Wider range of Customer Options - Single Dump / Double Dump / Gravity fed / Motorised / Pneumatic

•Reduced maintanance requirements.

•Heavy duty cast iron construction

•Compact and robust design.

•High quality airlock.

•Easy to maintain.

•Custom valves to suit specific requirements.

Anval DH series dump valve range is designed in a highly effective manner emphasizing on total sealing, continuous uninterrupted discharge, with long life and minimal maintenance.

Applications

It's typical application include dust collectors, hoppers, baghouses, conveyors and electrostatic precipitators handling materials of varying sizes from fly ash, cement, sand, limestone, sawdust and many more dry materials. The Range is intended for industries and applications where total sealing and occasional or regular discharge of solids is a requirement. The Valves have been designed for simple long life operation with minimal attention requirement with the only lubricated components being the bearings.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

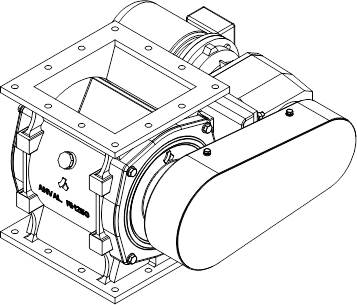

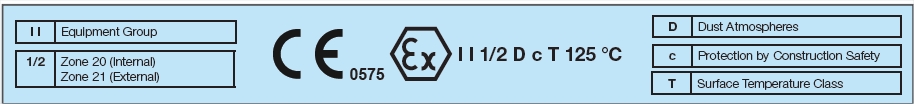

Rhx Series Atex Approved Rotary Valve

ATEX RHX SERIES - ROTARY VALVES

The ATEX certified Anval RHX Series Rotary Valves is designed for use in a wide range of applications from heavy mineral lumps to light flour dust where there is a potentially Explosive atmosphere.

ROBUST HIGH EFFICIENCY VERSATILE DESIGN

Anval have a vast and exciting selection of Rotary valves including the newly ATEX Certified RHX Series; specifically designed for Explosive atmospheres.

The RHX Series valves are ATEX marked and designed with the intention of being used in potentially explosive atmospheres, provisions have also been made for all essential Health and Safety requirements.

The Anval RHX Series valves are manufactured to robust design standards and an efficacious Quality Management System that enables the valve to operate under even the toughest conditions with minimal maintenance. This valve series is driven by ATEX approved geared motors for both direct and chain drive options, alternatively the valves can be supplied as "Bare shaft".

Opening Size : 150 to 750 mm

Flange Opening: Square

Temperature: Upto 125° C

Drives: Chain Driven / Direct Driven / Bare shaft

Material of Construction: Cast Iron

Capacity Range: Upto 469 m/hr Max.

RHX SERIES valves are compliant with the requirements of ATEX Directive 94/9/EC to handle tough, volatile applications with low maintenance requirements.

Features

•ATEX certified with protection by Construction Safety

•Heavy duty single piece cast iron body

•Available in Direct / Chain / Bare shaft options

•Wide selection of rotor types

•Equipped with "Labyrinth seals" for improved sealing

•Available with Gas or Grease purging

•Excellent Airlock perfromance

•Minimal maintenace requirement

Sealing Method

Perfect sealing is definitely required on the rotating shaft and Anval rotary airlocks adhere to it by using "labyrinth seals". To seal dust and achieve smooth operation, dust tight seal on a rotating shaft is required. Labyrinth seals are especially effective in environments with highly abrasive products and under differential pressure conditions.

Applications

The RHX Series can be used in Safety zones 20 (Internal) and 21 (External), in application areas such as steel, cement, power plants, mineral processing, chemicals, flour mills and other areas where a potentially explosive atmosphere may be present.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

Anval Valves

ANVAL is a designer, manufacturer and supplier of feeders and airlocks to powder and bulk materials handling industries. It is part of the ACTINON group of companies, an emerging global industrial equipment manufacturer for over the past two decades.

ANVAL has a growing range of feeders and airlocks to meet even the most demanding of applications. The company prides itself on using simple and elegant design solutions to provide what customers need to meet their performance requirements. Our innovative streak and our focus on job performance is our strength.

While powder and bulk materials handling is a problem common to many industries, their materials are not. From simple pellets to irregular lump coal, from sticky and stringy biomass to abrasive alumina, ANVAL’s in-house engineering team has provided solutions.

Our core product ranges to meet a variety of feeding, airlocking or isolation duties include:

Commitment to Quality

In today’s globalised world, quality is an overused word. At Anval, we equate this as our ability to correctly identify and then satisfy the needs of our customers.

In establishing our manufacturing processes, we have incorporated many of the ‘world’s best’ practises. Our aim is to harness all of the advantages of techniques such as TQM and lean manufacturing.

We also understand that in the real world when things go wrong, our Customers need to rely on our ability to get them going again, regardless of cause.

Customisation for Customers

Whilst we show a generic product offering, so often the solution is anything but generic. Anval recognises that our products need to be tailored to specific needs a customer has.

As such, we need to go the extra mile to work with customers. Our systems and designs are developed with that flexibility in mind. Our goal is to allow our customers the ability to shape our products to their needs, without penalty of time and additional cost.

For more information, please visit:

http://www.anval.net

https://edir.bulk-online.com/profile...ernational.htm