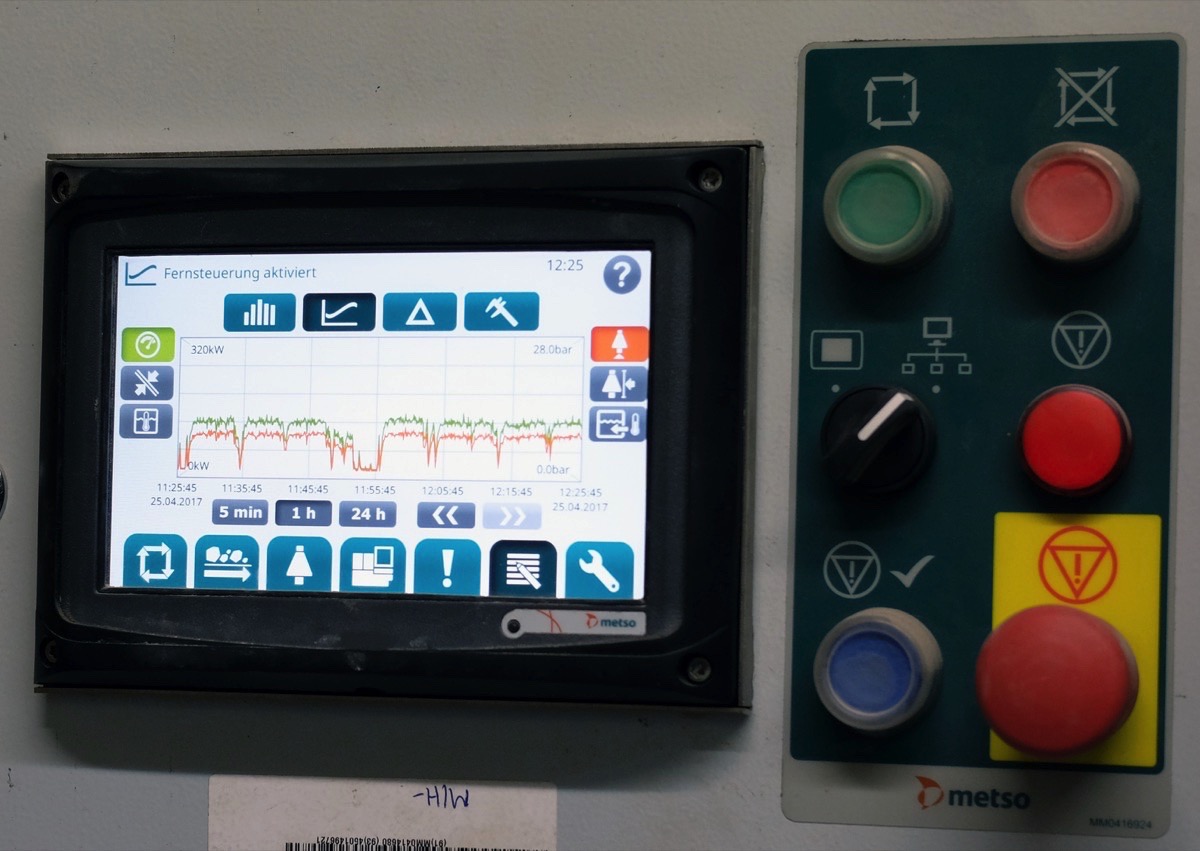

“During the first year, we have crushed with the GP330 over 1,800 hours. Everything has gone well, and all targets set for the end product quality and capacity have been met. Thanks to the IC50 process automation, everything in the crusher functions can be adjusted easily – a big improvement after the predecessor from the 1980’s.”

“To secure the non-stop operation in the future, we have signed a five-year Equipment Protection Plan with Metso. Our EPP contract includes regular inspections, main service functions and parts,” Kurt Schön adds.

Old Quarry with high-quality Products

The history of the Rammelsbach quarry in Rheinland-Pfalz goes back to the 1860’s, when the first extractions were made. In the 1930’s, Rammelsbach scored the status of the biggest quarry in Europe.Since 2001, the quarry is owned by Basalt-Actien-Geschellshaft (BAG), one of Europe’s biggest aggregates and building materials producers. The company offers its customers everything from stone: quality chippings, railway ballast and fine aggregates for asphalt, concrete and construction.In Rammelsbach, microdiorit called “Kuselit” per the village nearby, is extracted. The rock has solid density of 2,68 that makes is very well suitable for production of high-quality railway ballast. Some 50% of the quarry production goes to DB, German railways for nationwide use.

Counting on Quality

Instead of quantity, the Rammelsbach quarry is counting on constant, high quality.“Everything we do here is documented accurately. Of each 1,000-ton shipment of railway ballast, a sample is taken. Each stone we produce must follow the quality standards by both size, cubicity and purity,” Kurt Schön stresses.“In our production totally, we have six different research phases,” he adds.In addition to ballast, Rammelsbach produces everything that the region needs: different sized aggregates called “Edelsplitt” to produce asphalt, concrete and for general construction purposes.

Three Material Flows

Within the quarry process, the microdiorite is blasted and trucked first to the primary gyratory crusher. After that, material is screened into three different sizes: 0-32 mm size is separated, and a suitable mixture of 32-70 mm and 70-240 mm is fed into the Metso GP330 cone.

The crusher has 34 mm closed side setting and 22 mm stroke, providing cubical, 0-80 mm sized aggregates for further processing. The constant capacity processing the hard microdiorite is around 340 metric tons per hour.Microdiorite is abrasive, and crusher wear parts change interval is done after each 1900 operating hours. The new Metso offline oil filter is multiplying the lifetime of hydraulic oil, saving moneyThe 150-year-old Rammelsbach quarry has still reserves at least for 20 years to come. ■