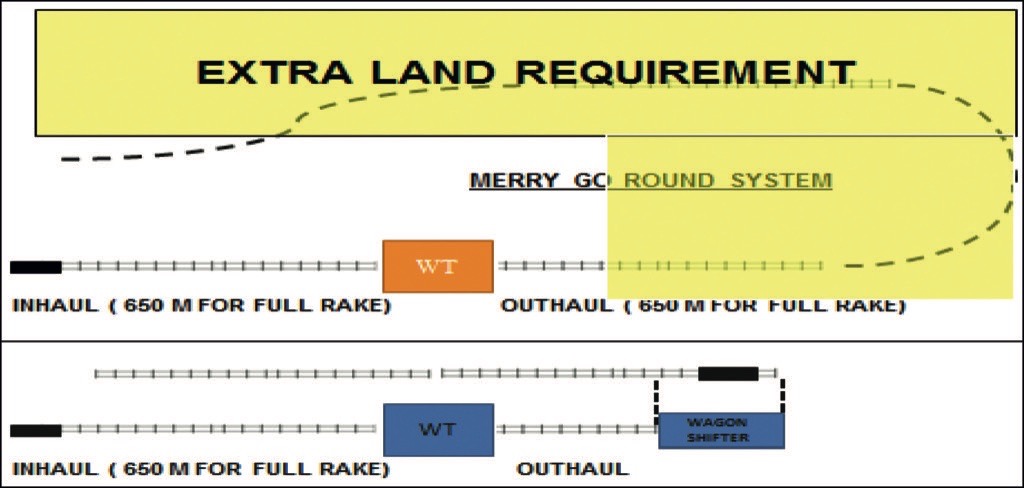

(From the archive of ”bulk solids handling", article published in Vol. 34 (2014) No. 2 , ©2014 bulk-online.com)As per the latest RDSO (Research Design & Standards Organization, India) G-33 rev1 guide lines, the requirement of railway line at haul in and haul out of a single wagon tippler system is around 650 m each considering full rake for a MGR (Merry Go Round) System.With increasing demand for power came demand for land to set up the thermal power projects requiring anywhere from 1090 acres (440 hectars) for 2x500 MW TPP, to 2440 acres (990 hectars) for 5x800 MW). The decision to go for super critical units increased the requirement of coal exponentially leading to an increase in conveying system capacities and land requirement to store coal in open stock yard, a method commonly followed in all thermal power plants across India. Independent power producers faced a new challenge of land availability.Typically a coal handling plant consists of facilities for unloading coal wagons either by wagon tipplers or track hopper, crushing coal to required size, storage in open stock yard and routing the coal to boiler bunker through conveying system.Wagon shifter plus pusher is equipment which is installed at the haul out of a wagon tippler to transfer the empty wagons to the parallel railway line as shown above.

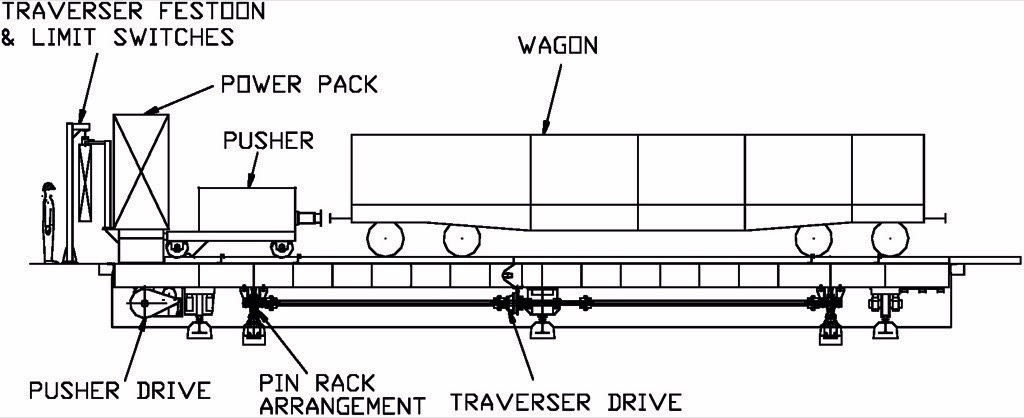

Considerable reduction of wagon hold time at thermal power plant could be achieved by this new equipment saving demurrage costs. Similar equipment was already in use in South Africa and China. Larsen & Toubro’s bulk material handling power business unit introduced this equipment in India for the first time through M/s Indiabulls Power Limited Bulk - UK.The traverse’s function is to accommodate an empty rail wagon exiting the tippler and move it from the entry to the exit rail track. It is a self-propelled machine running on straight and level rail tracks set at right angles between the aformentioned tracks. The traverser is also capable of handling an occasional full loaded wagon.The traverser comprises a travelling bridge mounted on three bogie units which run on three parallel land-mounted rails. The traverser has its own travel drive unit which comprises a hydraulic motor directly coupled to a lay shaft fitted with pin rack arrangement at both end. The traverse movement is done by the sprocket (coupled with lay shaft) and pin rack arrangement which is anchored at ground.

Retractable clicking stops are fitted to the traverser bridge to ensure wagons cannot roll off during traversing. These stops are retracted by hydraulic cylinders.The hydraulic motor and cylinder are powered by an on-board electrically driven hydraulic power pack. The electrical power and control cables are connected to the traverser by a cable festoon system.The traverser bridge section carries running rails which has the pusher positioned at the end further from the tippler with its hydraulic drive pack.The in go end of the Traverser has a locating bogie, this bogie has a different width of flanged roller than the other non-locating bogies. The first non-locating bogies of the traverse is placed at the centre and the last one is positioned at the pusher drive end of the traverser.Thus advantages of wagon traverser plus pusher is providing an optimal solution for reducing land requirement, hereby reducing also the capital investment and achieving an earlier breakeven. Such benefits are well accepted by clients like M/s India Bulls Power Limited or M/s GMR Chattisgarh Energy.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2014.

| About the Authors | |

| Hari Subramaniyam A.Business Development ManagerLarsen & Toubro, India |

■