A single-source provider for filling, palletising and packaging technologies, Beumer Group continues to pursue its ambitious goal of offering its customers sustainable solutions. In order to control, coordinate and display these processes, Beumer Group also provides warehouse management systems (WMS). These system solutions are tailored to the customers’ individual requirements.

For companies in the food and beverage, construction material, electronics and pharmaceuticals industries, the topic of safety when transporting and storing palletised products has become more and more important. These products must be palletised and filled reliably and securely packed in order to deliver them to the customers without damage. The intralogistics specialist Beumer has expanded its product portfolio with the fillpac filling machine and offers plants and systems for complete packaging lines as single-source provider.The fillpac can be flexibly integrated with existing packaging lines and can be optimally adapted to the customer’s conditions. In palletising technology, Beumer provides a graduated and comprehensive spectrum of high-capacity layer palletisers that form secure load units. The geometric precision and the stability of the palletised stacks enable easy storage and ensure secure conveyance to the packaging system downstream.

These plants and systems, in combination with the conveying technology also offered by Beumer, are meticulously coordinated with each other and have a very long service life. These systems are adapted in an optimal manner to individual customer requirements, such as machinery capacities, manufacturing output or storage space. In order to achieve reliable and efficient control of all of these processes, warehouse management systems (WMS) are provided, which can be tailored to the users’ requirements.

Warehouse Management System for Process Control

The Beumer warehouse management system is a web server application which controls and coordinates the entire packaging process, storage and preparation for shipment of products in an optimum manner. Control of materials flow, warehouse management and also the interface to the superior ERP system of the customer are integrated to form part of the system. All information from the packaging line, labelling, storage and shipment converges here. This ensures complete and absolute transparency of all products and processes. All persons involved in production can access the system, the logistic scheduler, warehouse employees or forklift operators. The functions and graphical user interface can be configured to meet customer-specific requirements. Thus the warehouse management system ensures financially sensible processes and transparent flow of goods which leads to shorter delivery periods.

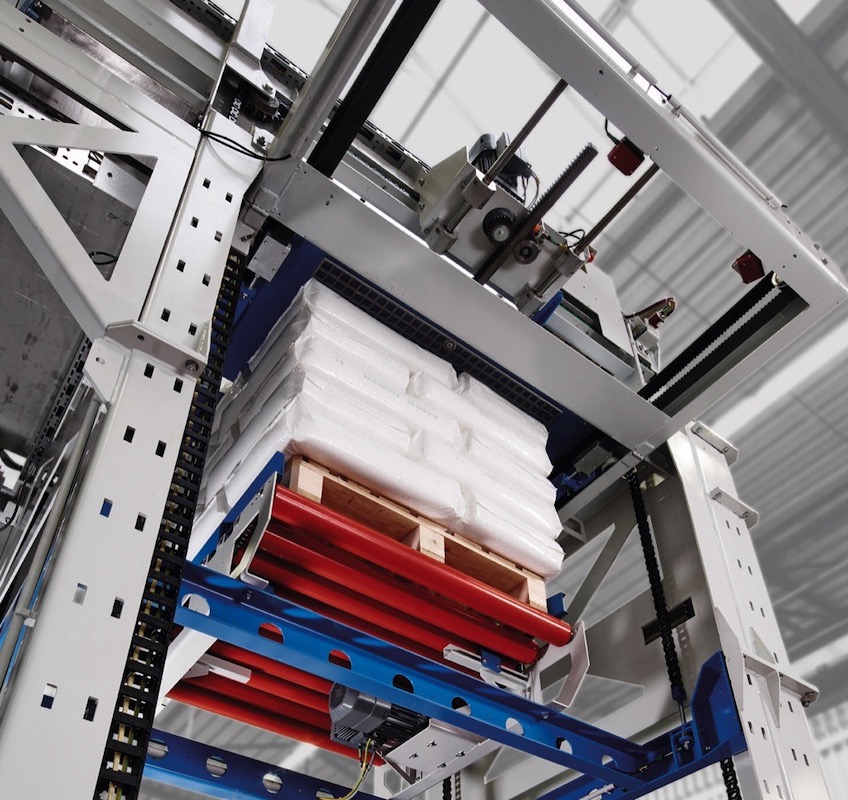

If the ERP system receives a picking order, it sends the information to a distributed control system and to the warehouse management system. The distributed control system monitors and controls the material flow from the silo, checks the product quantities, bagging, palletising and also securing of loads. The packed load units are then provided with a barcode. During this process, the warehouse management system is in continual data exchange with the ERP system.After the load units are delivered to the conveying system, the palletising technology stacks the boxes, bags or trays onto pallets in a secure and space-saving manner. These pallets are then transported on roller conveyors towards the Beumer stretch hood high-capacity packaging system. The stretch hood system wraps the loaded pallets with a special polythene film. This extremely weather-resistant packaging ensures the safety of the products during storage and shipment. They are then provided with a barcode.The warehouse management system includes also a main control system for fork-lifts which ensures that the palletised and packaged goods can be loaded quickly without prolonged intermediate storage. Therefore, the warehouse management system checks if the pallet is ready for collection at the belt conveyor, reads the barcode, assigns a specific storage space for the pallet and controls the corresponding fork-lift. In these processes, the warehouse management system is in continual data exchange with the ERP system.Any errors that could occur amongst the production, storage and shipment systems are avoided with Beumers warehouse management system, as are time-consuming searches. As all processes are defined chronologically, an automatic material reservation and provision process is enabled that is timely and tailored to demand. The warehouse and supply process that is positively driven also makes the production throughput clearly faster and more efficient.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2014.

| About the Author | |

| Peter SchmidHead of Sales Tailor Made SolutionsBEUMER Group, Germany |

■