Conveyor skirting is a product that maintains a dust seal between the chute structure and the conveyor belt. It is usually made out of rubber strips and mechanical grips, which keeps the rubber in place.

As materials enter the top of the chute, some is converted into dust particles as it falls.

Without a conveyor skirting system, the dust particles become airborne and escape the system, which will lead to loss of material and create a health and safety hazard.

What Type of Materials Handled Would Benefit?

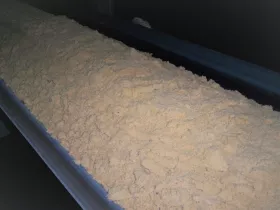

Almost all bulk handling materials would benefit from a conveyor skirting system. Bulkier materials, such as unrefined mineral ores, have a tendency to break off into smaller particles and form dust. Finer materials, such as sand, grain, sugar, salt and wood chips, would also benefit from a conveyor seal to prevent material wastage.

Key Conveyor Skirting Benefits

Dust Duppression

The primary reason to install conveyor skirting is to suppress dust. Dust poses a significant health issue as it can lead to respiratory issues and disease. Fine dust can also cause irritation, burning and damage if it gets into the eyes.

In areas where dust is poorly contained, lower visibility due to dust pollution can pose a serious safety hazard for employees. Dust particles can be reduced through dust suppression systems, such as a spray bar, however a conveyor skirting seal is an effective preventative measure at the initial point.

Minimised Material Loss

In a perfect world, 100 per cent of materials conveyed would arrive at their destination point. However, due to a range of factors such as conveyor speed, incline angle, roller/idler type (flat or troughed), material consistency, or environmental factors, materials are often spilled or blown off the belt. Effective conveyor skirting can reduce the amount of material lost by preventing spillage and airborne material wastage.

Reduced Conveyor Belt Damage

Without a conveyor skirting system, material can spill out and become lodged underneath the belt. Material caught between the belt and rollers will cause the belt to mistrack and become damaged. Having a conveyor skirting system in place will reduce the risk of preventable belt damage caused by material build up.

Lowered Cleaning Costs

Dust pollution, material spillage and buildup require ongoing cleaning and maintenance to ensure conveyor systems run safely and smoothly. Without conveyor skirting, a system will require more maintenance which can be expensive due to cleaning labour costs and downtime from system shutdowns.

Increased Overall Productivity

Conveyor skirting can increase a conveyor’s overall productivity. With health and safety incidents minimised and material loss prevented, a higher product yield can be achieved. Reduced conveyor belt damage, belt tracking issues and material build up means less time is spent on repairs.

Dynamic Sealing

DYNA Engineering’s Flexiseal® conveyor skirting has been especially designed with unique features, making Flexiseal® superior to conventional conveyor skirting.

Flexiseal® incorporates a dynamic design that, when compared to conventional conveyor skirting:

- Automatically compensates for varying belt movements, sustaining an effective seal

- Reduces further belt wear

- Automatically maintains correct pressure of the skirting rubber on the belt

- Does not require any adjustments

The low maintenance design uses a patented quick release clamping mechanism. The design incorporates a CAM to securely hold the rubber seal in place.

Other Benefits include:

Automatic Pressure Control Mechanism

Conveyor belt wear is a common issue that plagues conventional skirting systems. It is easy to overtighten conventional systems, which puts undue pressure on the conveyor belt and results in an increase in wear. Flexiseal uses an automatic pressure control mechanism which maintains the correct pressure of the skirting rubber on the conveyor belt, making it impossible to overtighten.

Consistently maintaining the correct pressure, combined with its high surface area and evenly distributed contact area, greatly reduces conveyor belt wear within the sealing area.

Diagonal Grooving Channels

A specially designed diagonal grooving channel helps Flexiseal to reduce stray material which can become trapped under the skirting system, and transports it back to the conveyor belt.

This helps reduce damage to the conveyor belt, as entrapped material can cause abrasive wear and grooving – a particular issue when conveying hard and abrasive material.

Quick Release System

Flexiseal has been designed to be as low maintenance and simple as possible. On conventional skirting systems, fasteners are required to keep the skirting in place. Fasteners can seize, cause material buildup, or rip and tear off.

DYNA’s design uses a quick release clamping mechanism to securely hold the rubber seal in place. When the seal eventually wears out, the quick release clamping system allows the new rubber strip to be inserted and clamped in position without adjustments.

No Adjustments required

On traditional skirting systems, frequent adjustments may be required to keep the skirting rubber in proximity of the conveyor belt to maintain the seal. As the skirting rubber and conveyor belt rub together, a groove begins to wear into the belt.

Flexiseal does not require any adjustments, due to its dynamic design. The curved rubber sections maintain contact with the conveyor belt regardless of seal wear, belt sag, belt condition or belt mistracking.

■