Further Improvement in Concrete Properties

The current state-of-the-art for crushed sand production is VSI shaping and wet or dry classification to reduce the total fines content. However, it is our belief – and our findings indicate – that further important improvement in concrete properties can be achieved if the properties of the very fine part of the crushed sand (≤ 0.125 mm) are modified (engineered).

Two tasks then have to be solved, in order to see if our hypothesis is valid also when applied to industrial scale production. The first task includes the concrete technology side, which would require a complete understanding of how and which fine particle properties affect fresh concrete properties. The second task involves finding an industrial solution that would render a controlled modification and optimization of the filler part properties possible also at aggregates quarries.

Otherwise, our findings would be only of scientific importance with limited practical relevance. What seemed to be a difficult task at the beginning turned out to be possible with the equipment readily offered by Metso Minerals. This is because if the fine (≤ 0.125 mm) part of the crushed sand is separated into different fractions by Metso’s static air-classifiers and stored into silos, we just need to find the best way of combining them afterwards.

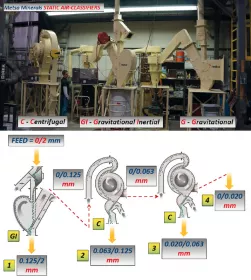

Moreover, two-stage dry air-classification is a concept that is already used today, providing in total four dry filler fractions to be mixed back either before or during the concrete production. The static air-classifiers are perfectly suited for aggregate operations, since they do not have any moving parts; the inside of their chambers is lined with ceramic lining, assuring very low wear costs even with highly abrasive feeds.

At the same time, they can be designed to accommodate the throughput necessary for most aggregate operations. In addition, they do not have the problems usually associated with the wet classification process (washing), i.e. space and environmental issues from de-watering ponds and operation problems in places where negative temperatures are reached in the winter time.

Developing a future Sand Solution

In order to proceed with the experiments to further elaborate the proposed hypo-thesis, great effort and care were taken in the preparation of a set of model materials (crushed fillers) that represent the complete range of local geological variety in Scandinavia. This involved collecting 4/22 mm crushed rock samples from 10 different quarries. Further processing included another step of Barmac VSI crushing to generate fines and screening of 0/4 mm crushed sand. Special care was taken to ensure that all the fines were generated only in this strictly controlled way.

Previous research findings within the COIN project and elsewhere had proved that the geometrical properties (such as shape) of the fine particles ≤ 0.125 mm can be affected by the crushing procedures applied. For example, an increase in VSI tip speed demonstrated an improvement in the properties of particles all the way down to and including the filler (≤ 0.125 mm or 120 mesh) sizes; moreover, those improvements proved the introduction of measurable changes in the fresh concrete properties.

After VSI crushing, the 0/4 mm crushed sand material was further split in two fractions – 2/4 mm and 0/2 mm. Almost 9 tons of the 0/2 mm fractions were then sent to Metso’s air-classification laboratory in Lebanon, Pennsylvania, USA, for controlled removal of filler and alteration of filler grading. This means that as much material below 0.125 mm as possible was removed and further split into fractions 0.063/0.125, 0.020/0.063 and 0/0.020 mm.

Industrially, this could be achieved by connecting a gravitational-inertial (GI) air-classifier in a row with two centrifugal (C) classifiers. This is illustrated in the flow chart in Fig. 5. As mentioned, already today there are aggregate operations that have two Metso static air-classifiers (GI and C) connected in a row to produce multiple different fine filler fractions.

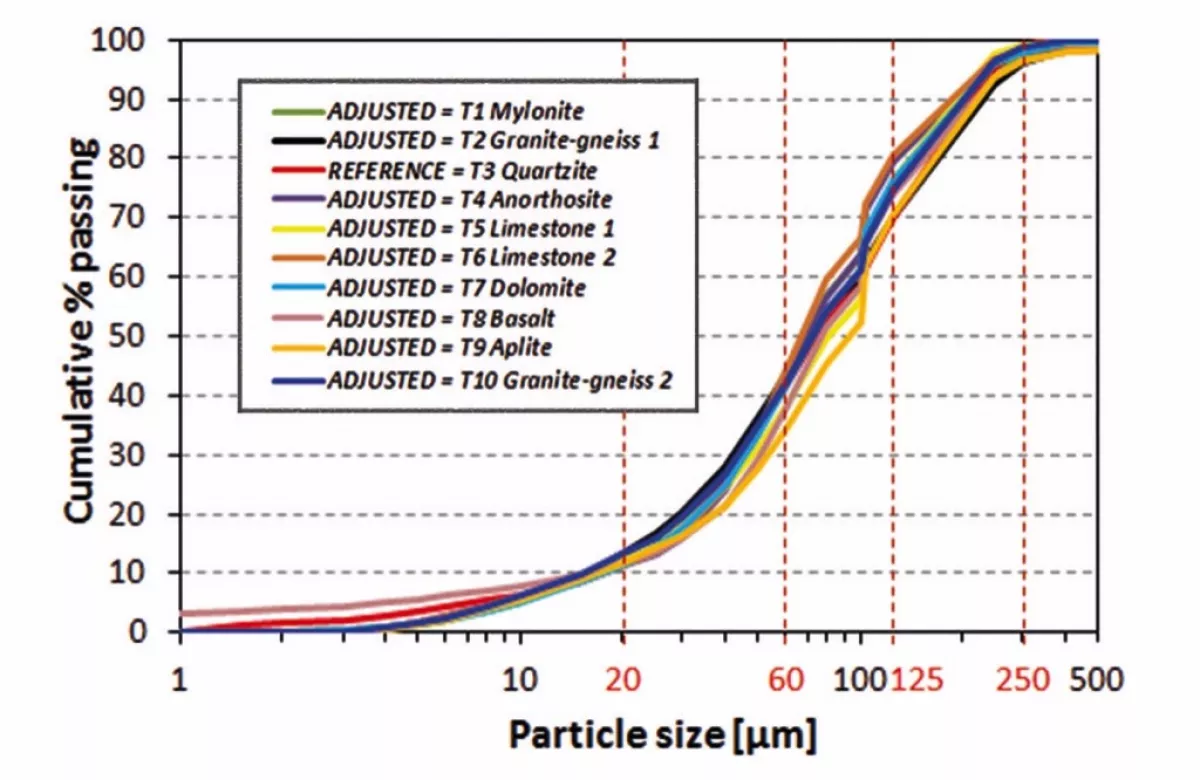

The air-classification experiments with the 10 different materials are now finished. The results demonstrated that the classification process of the equipment can be successfully adapted to a narrow desired result by adjusting the classification process parameters, i.e. the air-flow, which is regulated by the main air inlet valve and adjusted by the secondary air inlet valve (primary and secondary air ratio).

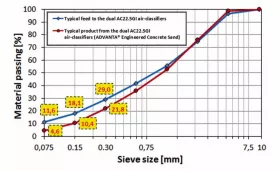

The success of the experiments can be illustrated (see Figs. 6 - 8) by the initial gradings of filler from all 10 crushed sands after the first stage of classification, an example of classification results (when the filler part is distributed into separate fractions), and the possibilities of recombining those fractions if one of the initial gradings is chosen as the reference.

The acquired filler fractions have now been delivered to the Norwegian University of Science and Technology where work within the COIN project will continue with the further elaboration of the knowledge on how the different filler characteristics affect the properties of fresh concrete.

Crushed Sand Application on the Aggregates Market

As described above, already today a technology for producing high quality manufactured sand that would be acceptably similar to that of the natural origin or at least “good enough” is available. Even though it is not always straight forward and not all the rocks can be classified as equally suitable for that, the questions for the future still are- can we make the manufactured sand even better than the natural, how, and, last but not least, why? An attempt to answer the first two parts of the question was given above in the article. If continuing with the last part of the question: aggregates constitute up to 75% of the total volume in concrete, while their price is second from the bottom, normally only water being less expensive. The aggregate prices in many places do not even keep up with the inflation, the only exception being natural sand, in some cases.

There can be two reasons for the sometimes high natural sand price, when compared to crushed aggregate. First, a good quality sand can make a huge impact on the cement consumption (the highest share of concrete self-price) to produce concrete with desired properties and second, because availability of good natural resources is almost exhausted in many parts of the world. This enlightens the two possible approaches in the crushed aggregate business (that can in fact be applied to any industry).

The first way is perhaps the most common, which is producing coarse aggregates that are virtually the same as from the other suppliers and trying to compete on the market with the price. This usually involves having only a marginal profit from every sold ton and an avoidable need to produce and sell huge volumes in order to render the operation profitable. For many huge aggregate quarries this has turned out to be especially difficult after the last financial crisis and, as a result, a lot of the so called “mammoth” quarries, operating on the first principle, have turned out to have overcapacities. Increasing the price at times, when everyone else has overcapacity as well and is selling virtually the same product, is of course a difficult task. Another type of approach would then be selling high added value (profit part of the price) crushed aggregate products at volumes that the market today can readily consume. In special market situations this is of course a normal occurrence, like for example in the mentioned case of lack of natural sand.

The basic commercial idea under future solutions for crushed sand from the aggregate producer’s point of view then lies in developing a technology to have a different kind of aggregate production approach. This involves not only trying to compete with the price but in fact producing high added value product that can even be brand named on the market to emphasize that it is unique, which has normally not been typical for natural sand or aggregates in general.

This interesting trend has already recently began and producers who have invested into considerably improving the quality of their crushed sand want to emphasize that it is different from the material that is co-generated in the coarse aggregate production process.

The two brand-named crushed sands to the author’s knowledge currently are the Advanta engineer concrete sand produced by LuckStone (www.luckstone.com) in Virginia, United States and the RoboSand produced by Robo Silicon (www.robo.co.in) in India. The Advanta crushed sand is in fact being produced by the aid of Metso’s static air-classification solutions.

Choosing the best Sand Production Process

It must, however, also be noted, that the new concepts described here is not a claim of inventing a “new type of bicycle” or a “miracle one button technology”. Is rather a concept that shows the unexplored possibilities of the technology that is available out from “Metso Minerals shelf” already today. The author will at all circumstances admit that the task of proving that a crushed sand product is worth a higher price (even if this is true) will not bet a simple and easy task. The main reasons for that are the aforementioned first historically unsuccessful attempts of using co-generated crushed fine material in concrete and second of all also because of legislative requirements that in many parts of the world can be discriminating towards the use of crushed sand, if it is tailor made for special performance in concrete and not a mime of an “ideal” natural sand. Then the aggregate producer can end up not only proving his clients that his product is worth the price, but in fact also proving to the authorities that it is allowed to be used for the projects that have to comply with the local standards.

Still every coarse aggregate production company has a wide range of choices of what to do with their surplus fines- dumping it in huge stock piles, trying to get rid of it at a very low or no price or try to make business out of it. If going for the last option, the next choice would then be choosing among the options of how sophisticated their crushed sand production should be. In some cases, the surplus fines can readily be of a quality that is suitable to be used in concrete in a blend with natural sand. However, this can also readily introduce some practical problems that need attention.

Such as that many concrete producers might not have an extra silo for the crushed sand available in their concrete plants and that if the fines content in the sand is extremely high, it would simply get stuck in the concrete producer’s aggregate silos at higher moisture content. The next step up the “ladder of crushed sand production” is probably installing a VSI, such as one of the Barmacs. That would allow considerably improving shape in the particle range down to and including the filler fractions. This would normally also have to be accompanied with a technique to reduce the fines content to an acceptable amount, such as a static air-classifier. Then if even higher quality of the sand is desired, the approach, described in this article, can be implemented, i.e. installing more than one air classifier and splitting the finest part of the sand in separate fractions.

Which is the best choice in each case, to the author’s opinion, will be rendered by the local market situation, however, to the same extent also by the fact, how much efforts in the long run the producer is willing to put forward in developing his product, not only on the technical side, but also actively working with technical support, sales and promotion. Or put it another way, crushed sand cannot be sold in the same way as for example 8/16 mm coarse aggregate, i.e. by sending a price offer and a declaration of determined physical/ alkali reactivity properties to a possible customer.

To the author’s perception, crushed sand needs much more technical kind of marketing and sales, in order to make it a success story. Those understanding the ready-mix concrete production business can compare this to selling concrete admixtures. Thus the author would advise one to be sure to have not only a skilled and professional team to deal with questions related aggregate but also concrete technology, and only then pursue the goal of developing a “different” aggregate production operation. This, is however, also true when analysing the market in which the producer operates. Thus not only such crucial factors as the availability of good natural sand or the overall price level of the aggregates should be considered.

Another important factor is in fact the technological level of the possible concrete clients. For example, Scandinavia in this case can be mentioned as a good example, since in general the largest concrete producers have experienced and most importantly highly academically educated concrete technology people. This means that there will be someone able to understand the possible benefits of the use of specially designed crushed fine aggregates. This also suggests, that companies having aggregate-concrete vertical integration have a larger potential of making money of high added value crushed sand production. This is since they can avoid the hard and time consuming work of getting the product into the market and also because they have the knowledge of concrete production technology readily available within the company.

The final remark would be that even though today crushed sand is still a developing business line among the minority of aggregate producers, one should keep in mind that without the risk and hard work it is doubtful possible coming to a great success, which in this case is a successful, more sustainable and profitable aggregate production in a long run.

■