Issue #1 Worn / Loose Slide Lagging

The rubber surface on this head pulley’s slide lagging has worn away and also a section of the lagging has come loose and is in danger of scraping the casing which can create heat and sparks. In addition, the reduced contact between the pulley surface and the belt can cause the belt to slip under load which will also lead to heat. Either of these heat sources could ignite a dust cloud inside the elevator, resulting in an explosion. Finally, if a perforation is worn into the casing dust can escape, and an extensive hot work repair will be required.

To help with early indication of these types of issues the installation of a speed switch on the tail shaft can sound an alarm and provide automatic shutdown before a dangerous belt split condition persists. Also a correctly positioned misalignment switch can detect a misaligned belt, a misaligned pulley or a piece of lagging that has come loose. These sensors can both alarm or shut down the bucket elevator so that corrective repairs can take place.

Misalignment outside

|

Misalignment inside

|

Touchswitch™ belt and pulley misalignment sensor

|

Whirligig® speed switch

|

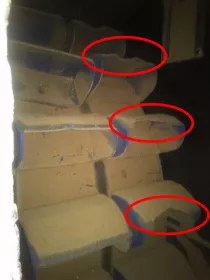

Issue #2 Broken Buckets

No matter the precautions taken, tramp material such as rocks, metal wrenches and wood boards can find their way into bucket elevators.

The impact of these foreign objects in the product stream takes a toll and can result in broken buckets. Impacts can also knock buckets loose from the belt, diminishing throughput and could actually cause a plug condition.

Screens and magnets located at the inlet can help capture tramp material before it enters the elevator. And plug sensors can help to detect a blocked chute. Also, heavier duty elevator buckets with stronger front lips can withstand more impact than lighter duty.

Jumbo heavy duty elevator bucket

|

Auto-Set™ flush probe plug switch

|

Issue #3 Excessive Bucket Wear

Aside from broken buckets, prematurely worn buckets can diminish throughput and make discharge inefficient. Another consequence could be early discharge resulting in material falling back down the upside of the elevator leg also known as back-legging. Back-legging just adds to the problem of premature wear because additional material ends up in the boot and the buckets must dig through it, wearing them further. Causes of this type could include an under tensioned belt, improper belt speed, excessive digging or material buildup in the boot, or the wrong style of elevator bucket being installed.

If the material being elevated is too abrasive for the bucket resin being used, employing digger buckets or changing to nylon or polyurethane buckets may help. 4B Components’ engineering group can assist with these issues along with any corrections to the elevator leg design, belt speed and bucket spacing.

4B Engineering

|

CCS Nylon Digger Bucket

|

Steel Digger Bucket

|