(From the archive of ”bulk solids handling", article published in Vol. 36 (2016) No. 6 , ©2016 bulk-online.com)

Extractive Industries have looked at utilising different materials and innovations for a variety of different reasons. Systems and newly invented materials have been developed and adapted to efficiently improve production and safety as well as decrease labour and breakdowns, ultimately with a goal of competitively reducing costs and maximising profit outputs.Metals, steels and rubber have been a large contributor to the foundations of our society and industries today. Co- existing with the development of metals and steels, industrial chemists and engineers in progressive countries have been able to break-down and engineer the internal structure of polymers and develop application specific composite materials.Notable industries, which have benefited from these advancements include:

- the automotive Industry with their use of polymers and composites replacing steel car bodies. Not only does this improve the fuel efficiency by reducing the car’s weight, it improves the safety rating of the vehicle by incorporating a crumple zone;

- the Aerospace Industry using engineered polymers and composites, providing freedom in design, improve fuel economy and in reduced areas susceptible to corrosion;

- the Department of Defence has incorporated engineered polymers to improve mobility, ergonomics and survivability of their infantry.

This paper has been written to clearly outline how the utilisation of polyurethane will benefit and revolutionise the bulk materials handling industry, in reference to:

- asset containment;

- chute lining;

- conveyor belt cleaning.

Background and History

Researchers have estimated that the first minerals were mined during the Aswan Period, using little more than stone, bronze and iron. It was estimated by different Egyptology researchers [1, 2] that the Great Pyramids, took between 10-20 years of hard labour, with an average workforce of 14 657 people (maximum of 40 000) and an estimated lump total of 5.9 million tonnes of limestone and granite moved. As anticipated, the bulk materials handling industry has developed tremendously since this period and processing equipment developed accordingly.Presently, this sort of tonnage would almost be trivial for an average quarry operating at 1.2 million tonnes per annum, to achieve in only a few years, with a workforce closer to 20-30 people.It is believed that hand-driven conveyors were first developed in the late 1700s, designed of leather and wood. Further developments and one hundred years later came the introduction of the conveyor belt, made from a combination of rubber, leather and canvas transporting coal, gravels and other ores. Various authors [3, 4, 5] recognise different inventors including: Thomas Robins, Henry Ford (founder of Ford Motor Company), Richard Sudcliffe, Henry Bessemer and the Swedish company Sandvik (famous for launching the Bessemer method for industrial scale steel production) for this new technology of improving the bulk materials handling industry. Progress utilising steels and alloys have been another key contributing component of the bulk materials handling industry, with improvements from raw materials such as tin and bronze, to alloy engineered and cast type materials such as NiHard, bisalloy and chromium carbide.

Polyurethane in Bulk Materials Handling

Following the incorporation of natural and synthetic rubbers, [6] and [7] recognise that Dr Otto Bayer and his team developed Polyurethanes in 1937, as part of the movement to formulate synthetic materials; a cheaper, more abundant replacement of natural rubber in World War 2. Rubbers had and have been used in the bulk material handling industry for several years.Manufacturing and production processes of polyurethanes immensely vary. Along with the materials’ infancy and introduction to the world, advances in technology has allowed the manufacturing process to be refined and further developed. These developments, according to laboratory testing, result in a variety of performance differences between the old and new generations.Chemical manufacturing company, Chemtura Corporation indicate that polyurethanes have been used in a variety of applications in the bulk materials handling industry. The material is developed by an exothermic reaction between alcohols of varying hydroxyl group molecules, poly-isocyanate and polyether or polyester polyols. Polyurethanes have been used in the materials handling for an extensive period of years, in applications such as screening media, seals, elevator buckets, pulley lagging and conveyor belt cleaners, usually for areas where material abrasion is an issue.Similar to rubbers, polyurethanes are manufactured and produced to fit a specific range of durometers, measured to identify the hardness of the material. Regardless of the durometer, polyurethanes are generally divided into two different classes: ether and ester, which assist with positioning them in an optimal environment. In summary, ether polyurethanes handle higher impact, whereas ester polyurethanes with their greater tear strength operate better where sliding abrasion occurs.In 2012, [8] introduced a new generation polyurethane conveyor skirting into the Australian bulk materials handling industry after hearing of its successes in the overseas bulk handling industry. According to a white paper, written by Pratt, this is due to its decreased coefficient of friction and high wear comparison against a standard styrene butadiene rubber (SBR). Lab and practical testing provided results with the polyurethane exceeding the rubber’s performance by eight to ten times depending on the asset material present and its installation environment, with the added benefit of zero-minimal conveyor belt damage compared to the previously installed rubber skirting.With this new discovery of improved wear life, polyurethane was installed in a variety of applications, not only replacing standard rubbers, but as a comparison retrofit against abrasion resistant steels and in environments where impact was another source of the issue.Unlike rigid materials such as steels and ceramics, polyurethane offers a material property described as Rebound Resilience. Accordingly to the ASTM D7121 - 05, Standard Test Method for Rubber Property, Resilience Using Schob Type Rebound Pendulum, this is a test commonly conducted on rubbers, designed to measure the ratio of energy released in deformation recovery to the energy that caused the deformation.Understanding this principle is key in the application exploration of this material, as it functions very differently to other previously recognised wear materials.Unlike steels and ceramics, which convert almost 100% of the impact energy, due to their stiffness properties, into abrasion wear and deflect the product (or crack/shatter in some cases when the impact force is too great), polyurethanes absorb the supplied potential and kinetic energies and momentum of the material, before deflecting it and under most circumstances, resulted in less wear.US-based polyurethane manufacturer Argonics Inc tested and evaluated the Rebound Resilience over several different polyurethane durometers and the results are provided in Table 1.

| Polyurethane Durometer | Rebund Resilience | Recommended Application |

| 58A | 77% | Fine Particle Abrasion,Minimal Impact |

| 74A | 80% | Fine and Wet Material Abrasion,Minimal Impact |

| 80A | 77% | Up to 20 mm minus, Wet Material Abrasion, Large Impact |

| 83A | 53% | Up to 50 mm minus Material Abrasion, Large Impact |

| 93A | 35% | Up to 125 mm minus, Material Abrasion, Large Impact |

From this experiment, it was demonstrated that the even (Argonics defined as) durometers have a higher rebound resilience, compared with the odd (Argonics defined as) durometers.It was suggested that the ether polyurethane handled large impact, although the larger rock offset this compromising the material due to its weaker cut and tear resistance. The case studies conducted at the ACT and Victorian quarries, later confirm and demonstrate this theory, based on the combined use of the low and high durometer polyurethanes.

Case Studies in Extractive Industries

Polyurethane — Case Study 1

In 2013, a case study was started at a concrete plant of one of the world’s leading heavy building materials companies, producing aggregates, including stone, gravel and sand to premixed concrete used on residential, commercial, civil or industrial projects. The site uses an aggregate weigh hopper constructed out of sheet steel handling aggregate material 20 mm, 14 mm, 10 mm, 7 mm and sand. Steel was typically used in hopper construction due to its robust properties, and for this application it needed to withstand the high volumes of highly abrasive materials being handled.The position of the hopper at the Brooklyn site meant that the aggregate and sand was dropped from several upper levels down into the hopper itself, 2-3 m impact height, causing a high level of abrasion to the internal steel surface. As a result, product was being lost through cracks and holes that were developing. Steel patches had been welded in as a “quick fix.” However, the appearance of the abrasion damage was becoming more frequent, resulting in more frequent plant shutdowns. This was significantly accumulating labour costs due to the need for specialised maintenance with poor accessibility and confined space requirements.

Over the three year period this application was frequently monitored. Several observations were made by the site during and following the installation which served as additional benefits. It was suggested that the polyurethane was lightweight and easy to work with. Another noticeable observation, was that the hopper experienced a significant reduction in noise. Table 2 shows all the different types of steels/alloys which have been used to line and patch the hopper an unknown period of time against the polyurethane wear liner, in which photos were taken after 18 months after the installation.

| Application | Concrete Plant — Aggregate Weigh Hopper |

| Product handled | Aggregate (20 mm, 14 mm, 10 mm, 7 mm, sands) |

| Concrete plant production | 90 m³/hour |

| Impact height | 2 - 3 m |

| Issue being solved | Premature wear liner failure |

| Material replacement | Steel |

| Maintenance frequency | 4 - 6 months |

| Polyurethane type installed | 25 mm thick 93A durometer polyurethan |

| Installation date | January 2013 |

| Study conclusion | January 2016 – plant upgrade |

During March 2016, a site visit was conducted where it was confirmed that the hopper which had been holding the liner, had since been removed. Increased demand requirements of site had resulted in the plant receiving a larger new hopper with improved productivity and therefore the study was never concluded.

Polyurethane — Case Study 2

Following success with polyurethane wear liner, the company elected to trial the material in another application, this time in a wok. The wok style apparatus is purpose built to mix the bulk concrete in preparation, ready for transit in mixer trucks. The wok lining experiences a narrow and concentrated impact area, handling high volumes of highly abrasive aggregate (20 mm, 14 mm, 10 mm, 7 mm) and sand particles.

Prior to the polyurethane, the site had performed trials in rubber and ceramics. Due to the concentrated high volume impact of the abrasive aggregate, after a few weeks, the tiles became dislodged and fell away. With an exposed hotspot and the buckling ceramics, caused by the curved surface compromising the bond of the ceramic, resulted in the individual ceramic modules falling off. Rubber was installed as an interim wear liner, but failed shortly afterwards.

| Application | Concrete Pant — Aggregate Wok |

| Product handled | Aggregate (20 mm, 14 mm, 10 mm, 7 mm, Sands) |

| Concrete plant production | 70 m³/hour |

| Impact height | 0.5 m |

| Issue being solved | Premature wear liner failure |

| Material replacement | Ceramic and rubber |

| Maintenance frequency | Rubber (1 month) and ceramic (10 months) |

| Polyurethane type installed | 13 mm thick 93A durometer polyurethan |

| Installation date | September 2014 |

| Study conclusion | Still continuing at March 2016 |

Ceramic Imbedded Polyurethane

With the evolution of polyurethane in the industry, understanding of the rebound resilience and experiencing the capabilities of ceramics in the bulk materials handling industry, combinations of the materials have been utilised to further prolong wear liner life. Similar to the rubber backed ceramic tiles developed earlier, a ceramic imbedded polyurethane was designed to handle impact. Ceramics are suggested to have wear resistant features such as its extreme hardness and have been recorded to excel in applications involving punishing abrasion. With the flexibility of the polyurethane (used to absorb and disperse the assets’ energy), combined with the hardness of the ceramics several case studies proved a successful result.

Ceramic Imbedded Polyurethane — Case Study 1

An initial trial was conducted in a smaller Tasmanian quarry producing more than 700,000 tonnes a year of hard rock dolerite products, supplying the construction industry with aggregate in road base materials. In addition to their fixed plants, the quarry operate a modern fleet of track-mounted mobile crushing and screening plants, comprising primary, secondary and tertiary units, screens and pugmills. The plant can be configured to suit many applications with crushing and screening units having a production capacity of up to 250 tonnes an hour. A consequence of the volume of their crushing operations was the high frequency replacement of the existing steel Hardox wear liner, having a wear life on average of 5 months.

Continuous site visits and interviews were conducted over the three year failure mode study. A replacement was installed shortly after the conclusion of the investigation.

- At 15 months post installation, it was reported by a business partner that the tile showed wear in some positions, but not in others.

- At 24 months, during a feedback interview, the tile was rotated to a position where no visible wear was present.

- At 36 months, a replacement tile was installed

| Application | Screen Loading Point |

| Product handled | 40 mm minus crushed Dolerite |

| Concrete plant production | 250 tonnes/hour |

| Impact height | 0.3 - 0.4 m |

| Issue being solved | Premature wear liner failure |

| Material replacement | 20 mm thick Hardox steel liner |

| Maintenance frequency | 5 months |

| Polyurethane type installed | 50 mm thick 80A imbedded with ceramic |

| Installation date | February 2010 |

| Study conclusion | March 2013 |

Ceramic Imbedded Polyurethane — Case Study 2

Following the success of the Tasmanian quarry, other opportunities appeared to trial polyurethane including at a busy metropolitan quarry for an ACT-based building and construction materials supplier. In this case, the maintenance supervisor was receiving regular reports of failed worn liners and consequently was looking for a way to improve the efficiencies of their transfer chute. It was observed that 20 mm Hardox steel lining had previously been installed, but not coping with the large bulk volume being conveyed at this site. The severe 2 metre drop height of the chute is severe which led to the alloy lasting just 10-14 days before a replacement liner was required.Following initial installation of the plain polyurethane tiles, the maintenance supervisor advised that its environment conditions had proven too severe for the 83 Durometer material, further supporting the recommendations made in Table 5.

It was also observed, Fig. 5, that the path of the material had been impacting the edge of the tile rather than the front. This had in-turn contributed in compromising the liner panel and thus increased the wear rate of the tile.

| Application | Chute above Secondary Cone Crusher |

| Product handled | 150 mm to 200 mm minus Basalt |

| Concrete plant production | 350 tonnes/hour |

| Impact height | 2 - 3 m |

| Issue being solved | Premature wear liner failure |

| Material replacement | 20 mm thick Hardox steel liner |

| Original maintenance frequency | 10 - 14 days |

| Trial 1 | |

| Polyurethane type installed | 50 mm thick 83A Durometer polyurethane tile |

| Installation date | 16/06/2014 |

| Study conclusion | 2 weeks |

| Trial 2 | |

| Polyurethane type installed | 83A Durometer polyurethane tile imbedded with ceramic |

| Installation date | 03/07/2014 |

| Study conclusion | 8 - 10 months (other locations 12+ months) |

Ceramic Imbedded Polyurethane — Case Study 3

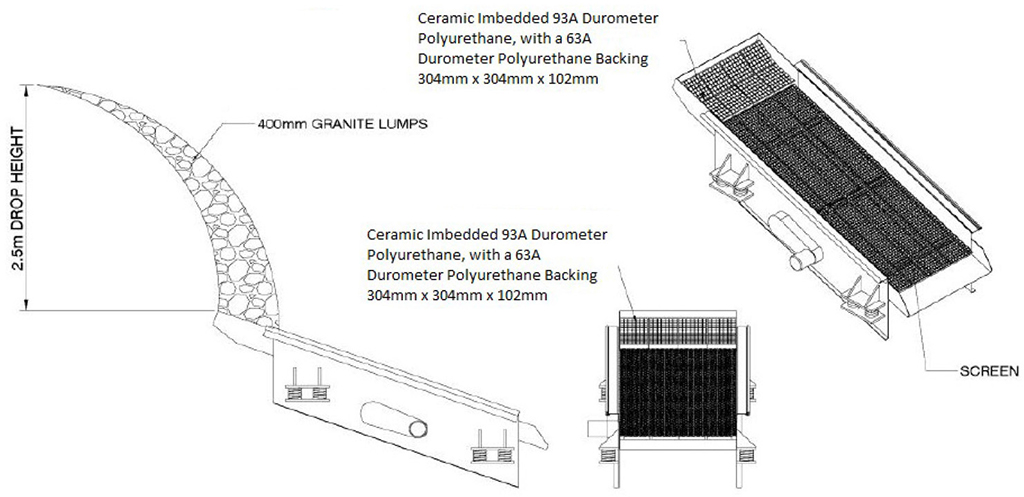

In 2013, trials were conducted at a granite quarry in south east Victoria, having recorded an estimated production to be 650,000 tonnes per annum. It was advised by the quarry manager that the fixed plant continued to experience high amounts of wear, complicated further by a poorly designed chute system. In summary, it was advised that the site had been using 16 mm Bisalloy plates, whilst suffering extreme abrasion damages, had been offering a wear life of 5 days, before requiring replacement or patching. The quarry manager believed this to be a result of the lump size (400 mm minus), combined with the witnessed impact height of 2.5 m.

Initially, plain 83A durometer polyurethane tiles were installed in this application, however they were removed shortly afterwards, due to the extreme abrasive properties of the granite, further supporting the data listed in Table 6.

| Application | Screen Loading Point |

| Product handled | 400 mm minus crushed granite rock |

| Concrete plant production | 350 tonnes/hour |

| Impact height | 2.5 m |

| Issue being solved | Premature wear liner failure |

| Material replacement | 16 mm thick bisalloy plate |

| Original maintenance frequency | Weekly patching |

| Trial 1 | |

| Polyurethane type installed | 50 mm thick 83A Durometer polyurethane panel |

| Installation date / Wear life | 2 days |

| Trial 2 | |

| Polyurethane type installed | 100 mm thick combined 63/93 Durometer ceramicpolyurethane |

| Installation date | 03/07/2014 |

With the two key elements of impact and abrasion present in this environment, a dual durometer ceramic imbedded polyurethane panel was installed. A 63 duro-meter polyurethane was trialled as a backing to absorb energy provided the constant granite flow, due to its high rebound resilience, combined with a 93A ceramic imbedded polyurethane (handles maximum lump size). Due to these environment parameters, this liner was developed application specific.

Several site visits and interviews were conducted over a period of 24 months until the fixed plant was upgraded, the quarry manager had recorded that he had replaced the panels once and considered this installation as a significant success.

Conclusion

Due to its rebound resilience and ability to absorb energy when installed in applications involving material impact, polyurethanes in the extractive industries have proven to offer a variety of different solutions. Like any material, it’s important to understand its optimised environment capabilities and limitations before recommending or installing. When exposed to applications involving impact and abrasive environments with smaller lumped material, it was concluded that polyurethanes provided higher abrasion and impact resistance than rubbers and ceramics, however when larger lumped materials were present, liners containing polyurethane could be used but a combination of polyurethane (to absorb impact) and ceramic (to handle the material abrasion) functioned even better with exceptional results.

Acknowledgements:

Kinder Australia Pty Ltd would like to acknowledge Argonics Inc for their support in providing laboratory reports and intellectual property. The author would also like to acknowledge each of the extractive industries mentioned in the case studies, who provided financial support and testing environments.

References:

- New World Encyclopaedia, http://www.newworldencyclopedia.org/entry/Great_Pyramid_of_Giza

- National Geographic, http://nationalgeographic.org/encyclopedia/quarry/

- Winn, C.: I Never Knew That About Irelane, Ebury Publishing, London, 2006, pp. 87.

- Walker, S.C.: Mine Winding and Transport, Elsevier Science Publishers, Netherlands, 1988, pp. 6.

- Merriam-Webster, Merriam Webster Collegiate Encyclopaedia, Encyclopaedia Britannica Company, Springfield, Massachusetts, USA, 11th Edition, 2004, pp. 116.

- Clemitson, I.R.: Castable Polyurethane Elastomers, CRC Press, Taylor and Francis Group, Florida, USA, 2008.

- Prisacariu, C.: Polyurethane Elastomers – From Morphology to Mechanical Aspects, Springer Wien, New York, USA, 2011.

- Pratt, C.: The New Generation of Conveyor Skirting; Australian Journal of Mining, 2010.

| About the Authors | |

| Sean E. KinderKinder & Company Pty. Ltd., Australia |

■