Re: Reclaiming Of Fertiliser From The Warehouse

Hello,

The reclaimer machine by the name ‘Bi-rail scraper with bucket elevator and discharge boom’ could be a solution. In this arrangement, the scraper reclaimer runs on two rails at the middle of silo. It reclaims the fertiliser from stockpile front face and discharges into a conveyor supported from shed side at some 6 to 7 m elevation. The rails remain buried in fertiliser, but machine itself clears it for its advancement. The shed floor is plain horizontal without civil work complexities. I saw this machine at urea plant in Kanpur. The working of machine and system is neat, clean and silent (without fuming and roaring engines of payloader, etc. in enclosed shed). The well known manufacturer from Gujarat, along with famous name from Germany, had supplied around 6 such machines in fertiliser plants in India (by 1981). Probably, there would be more such machines by this time. In this system, the stacking is by overhead conveyor along with traveling tripper, supported from silo roof structure.

Semi-portal and portal type scraper reclaimer machines have been also used frequently in fertiliser plants in India.

The aforesaid installations are mostly in public sector plants. Possibly, these are proven high-tech and world class system as on today.

Ishwar G. Mulani

Author of Book: Engineering Science And Application Design For Belt Conveyors (new print November, 2012)

Author of Book: Belt Feeder Design And Hopper Bin Silo

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India.

Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Reclaiming Of Fertilser From The Warehouse

Respectable Mulani Ji, Thanks for giving us such valuable information.

Thanks again

Anil Saeth

The reclaimer machine by the name ‘Bi-rail scraper with bucket elevator and discharge boom’ could be a solution. In this arrangement, the scraper reclaimer runs on two rails at the middle of silo. It reclaims the fertiliser from stockpile front face and discharges into a conveyor supported from shed side at some 6 to 7 m elevation. The rails remain buried in fertiliser, but machine itself clears it for its advancement. The shed floor is plain horizontal without civil work complexities. I saw this machine at urea plant in Kanpur. The working of machine and system is neat, clean and silent (without fuming and roaring engines of payloader, etc. in enclosed shed). The well known manufacturer from Gujarat, along with famous name from Germany, had supplied around 6 such machines in fertiliser plants in India (by 1981). Probably, there would be more such machines by this time. In this system, the stacking is by overhead conveyor along with traveling tripper, supported from silo roof structure.

Semi-portal and portal type scraper reclaimer machines have been also used frequently in fertiliser plants in India.

The aforesaid installations are mostly in public sector plants. Possibly, these are proven high-tech and world class system as on today.

Ishwar G. Mulani

Author of Book: Engineering Science And Application Design For Belt Conveyors (new print November, 2012)

Author of Book: Belt Feeder Design And Hopper Bin Silo

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India.

Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com

■

Reclaimation Of Urea

As always Mr. Mulani seems to be right on the mark. Portal scrapers are the most commonly used reclaimers. They are installed in an A frame structure. You need to verify the maximum height of your material so that it does not pack and stick together on the bottom of your pile. Prills can not be piled as high as pellets etc. Equipment vendors don't really care about this and are willing to make your pile too high to try to convince you that you have enough capacity. You might want to consider a tripper with a DSH discharge nozzle to minimize fine creations when making your storage pile. By reducing the fines you help eliminate the material clumping together. Your bagging, truck loading and rail car loading can be fed from the reclaim system. They should not be in the same building for dust reasons. You need to design your building to be completely enclosed, if you get water on your urea you will have big problems.

Good Luck with your project and feel free to contact us if you need any assistance.

Best Regards

Liam Kiley

Ultragen Ltee ■

Re: Reclaiming Of Fertiliser From The Warehouse

Thanks Gentleman for your valuable advise.

Anil

Good Luck with your project and feel free to contact us if you need any assistance.

Best Regards

Liam Kiley

Ultragen Ltee

■

Re: Reclaiming Of Fertiliser From The Warehouse

Dear Liam, Could you please provide the picture/sketch of tripper with a DSH discharge nozzle for minimizing fine creations and some write up on the same.

Thanks again

Anil

Good Luck with your project and feel free to contact us if you need any assistance.

Best Regards

Liam Kiley

Ultragen Ltee

■

Dsh Systems

Here is the website for DSH. I do not work for or represent DSH. I am pretty sure this equipment was developed for urea handling but you will have to confirm with them. I believe that this equipment is ideally suited to the stock piling of urea.

http://www.dshsystems.com/

You would just install the dsh on the discharge(s) of the tripper conveyor. As always proper material handling rules should be followed. You would also probably want to minimize the support beams crossing under the conveyor or put chineese hats (it is a common expression) on them to prevent dust creation and wear.

Good luck with your project ■

Re: Reclaiming Of Fertiliser From The Warehouse

Thanks Gentleman,for your valuable advise..

Anil Seth

http://www.dshsystems.com/

You would just install the dsh on the discharge(s) of the tripper conveyor. As always proper material handling rules should be followed. You would also probably want to minimize the support beams crossing under the conveyor or put chineese hats (it is a common expression) on them to prevent dust creation and wear.

Good luck with your project

■

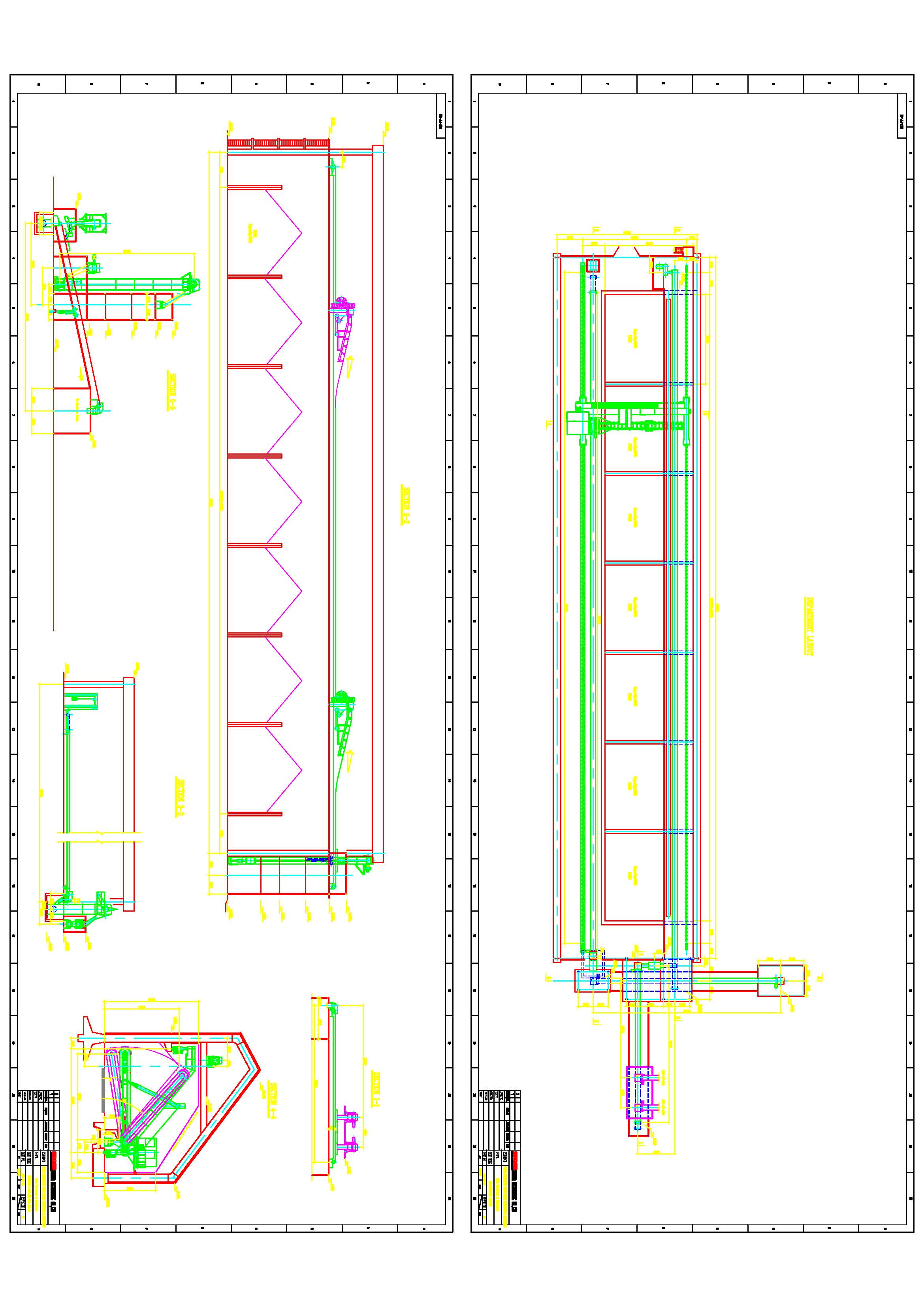

Sinoma Semi-Portal Reclaimer For Fertilizer Warehouse

Good day Mr Seth

We have ever supplied several sets of semi-portal reclaimer for fertilizer warehouse. Attached the picture of the reclaimer we

supplied in 2011 for Omnia(South Africa) Group PGAN warehouse. In this project we designed and supplied entire conveyor

system for the PGAN warehouse,including belt conveyorsbucket elevatertripperreclaimer and vibrating feeder. If you are

interested in this type of system please feel free to contact me.

Best regards

Chen Bo

Sinoma Yangzhou Machine Manufacture Company

Tel:+86 15105252769

E-mail: sinomayz@gmail.com

■

Bob Chen

General Manager, Yangzhou FusionBMH Engineering Co., Ltd.

Xian Jiaotong University Industrial Zone A3-211,

Hanjiang District, Yangzhou City, 225000 China

Mobile:+86-15105252769

E-mail: sinomayz@gmail.com or fusionbmh@gmail.com

Website: www.fusionbmh.com (English) or www.fusionbmh.cn(China)

Sinoma Semi-Portal Reclaimer For Fertilizer Warehouse

Good day Mr Seth

We have ever supplied several semi-portal reclaiming system for fertiler warehuose in South Africa and Russia. Attached some pics of the semi-portal reclaimer we suppled in 2011 for South Africa Omnia Group PGAN warehouse. We designed and supplied the entire conveyor system,including belt conveyersemi-portal reclaimerbucket elevator and vibrating feeder. If you are interested in this type conveyor system please feel free to contact me.

Best regards

Chen Bo

Sinoma Yangzhou Machine Manufacture Company(China)

Tel: +86 15105252769

E-mail:sinomayz@gmail.com

Attachments

■

Bob Chen

General Manager, Yangzhou FusionBMH Engineering Co., Ltd.

Xian Jiaotong University Industrial Zone A3-211,

Hanjiang District, Yangzhou City, 225000 China

Mobile:+86-15105252769

E-mail: sinomayz@gmail.com or fusionbmh@gmail.com

Website: www.fusionbmh.com (English) or www.fusionbmh.cn(China)

Urea Storage And Reclaim

I think you will need a entire portal scraper not a semi portal and a supplier who knows the difference. I am sure Sinoma can make a design for you for a portal type scraper. FLS, FAM and AMECO have a lot of experience moving and storing urea and have standard designs for urea storage and reclaim. Again as noted urea is special in the sense that it is so hydroscopic and you need to reduce the creation of fines to assist in the prevention of lumps and the bottom of your pile when it becomes packed. You also need to limit the height of your pile. Find a consultant with experience storing urea so that you do not end up with a high maintenance operation. IFFCO has many installations using the above noted equipment in India. I am sure the expertise is there also. Other than at the pelletizer where there is no choice and you will screen your material again anyways, fertilizer companies do not like bucket elevators moving their final product

Best Regards ■

Re: Reclaiming Of Fertiliser From The Warehouse

Dear Chen, Thanks for your advise.

Anil Seth

\

We have ever supplied several semi-portal reclaiming system for fertiler warehuose in South Africa and Russia. Attached some pics of the semi-portal reclaimer we suppled in 2011 for South Africa Omnia Group PGAN warehouse. We designed and supplied the entire conveyor system,including belt conveyersemi-portal reclaimerbucket elevator and vibrating feeder. If you are interested in this type conveyor system please feel free to contact me.

Best regards

Chen Bo

Sinoma Yangzhou Machine Manufacture Company(China)

Tel: +86 15105252769

E-mail:sinomayz@gmail.com

■

Don't Get Stuck In The Wet Urea.

From the foregoing it seems that moisture ingress rather than dust generation is the problem. A 900m shed is quite a beast and very difficult to keep dry if mobile plant is used. The proposed Chinese semi portal requires a shed which is mainly empty. About 35% is useful storage: the rest is not so fresh air and a clumsy machine. If you must have a shed so long (???) you must minimise indoor traffic or eliminate it altogether. That can be done by placing a central overhead inbye conveyor down the middle of the roof, complete with tripper.This will enable much better filling of the shed. For reclaim, run two sets of grabs alongside the tripper and discharge into a bin, with bagging plant, spaced at say 100m travel distance. Most of the time the grabs will only travel 50m to reach the bagging plant being operated. This system is completely dry and dust sealed. you can dump material into any cell while you are reclaiming it. No other technique will do that! It's how ships do it most of the time.

Conveyors are not always the answer and neither are fancy expensive reclaimers (with built-in standing walls, to boot). ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Reclaiming Of Fertiliser From The Warehouse

Here is the website for DSH. I do not work for or represent DSH. I am pretty sure this equipment was developed for urea handling but you will have to confirm with them. I believe that this equipment is ideally suited to the stock piling of urea. ■

Reclaiming of Fertiliser from the Warehouse

In India,conveying of Bulk Urea from warehouse to bagging plant is mostly done by using front end loaders. The front end loaders scoop the material from the heap(inside warehouse) and then feed it to the mobile hopper (above conveyor which is feeding to the silo top in Bagging plant).We have recently visited an upcoming facilities near a port,where 900 m long shed is constructed to for storing,bagging and dispatch of urea.By using above method of reclaiming the chances of accident will increase,the floor inside the warehouse always be wet,there shall be strong smell always inside the warehouse and will not give suitable atmosphere for the workers inside the warehouse. Being a little knowledge of handling bulk, the system of reclaiming of fertilizer(apart from reclaimer system) can be designed as mentioned below.

Provide special Augurs underground the floor,at suitable intervals and then raised(inclination) the level of Augurs near the conveyor and feed directly in to it.

We need advise from the Hon members of this forum.

Anil Seth ■