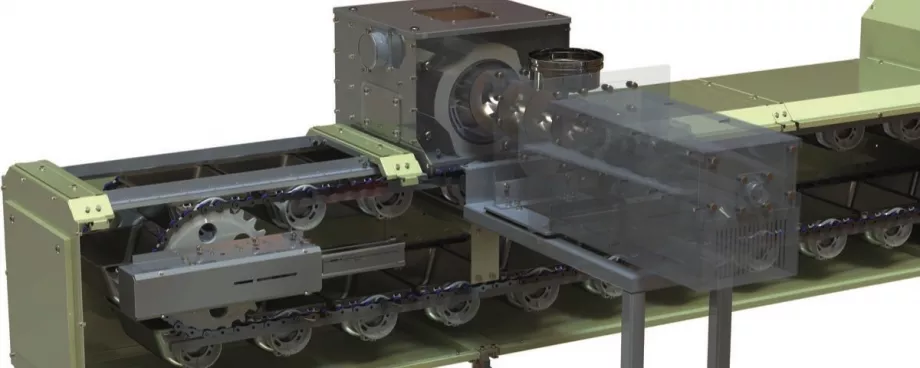

Simatek Drum Feeder with Forced Feeding System

By adding a screw feeder module to the patented Simatek Drum Feeder it is possible to secure a high filling degree of the elevator buckets. This feeding system is based on individual batch feeding of the elevator buckets without product spillage. In combination with the Simatek Drum Feeder it is possible to convey with elevator buckets without overlap. This is to eliminate mechanical contact between the buckets, friction and the use of guides. Conveying with FRB (Free Rotating Buckets) the system will ensure much more operational reliability as well as minimum wear.

- Raw meal

- Abrasive powders

- Fine granulates

- Premix

- Explosive powders

- Complex powders

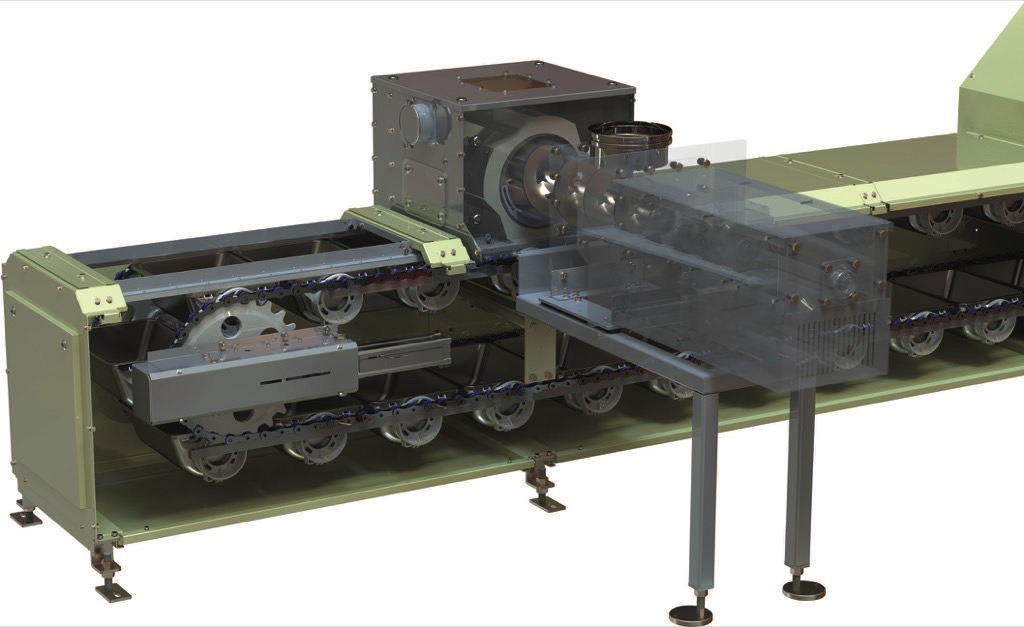

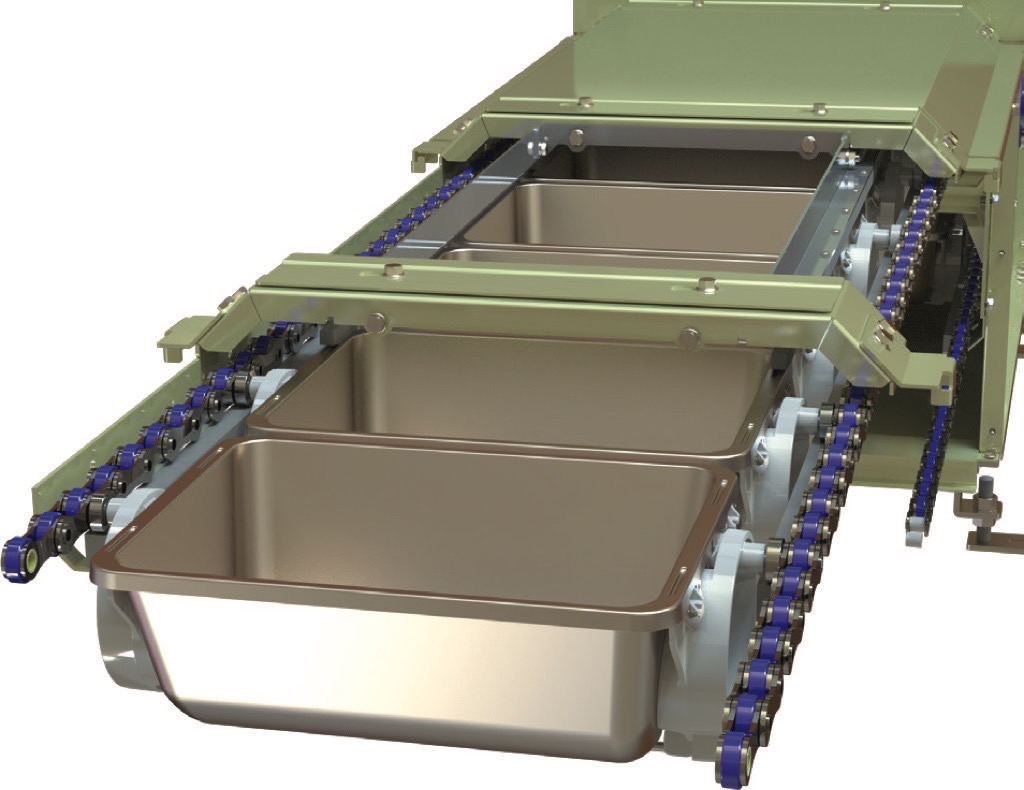

- Buckets with bearing suspension

In traditional pendulum bucket elevators the buckets are suspended between parallel roller chains. However, certain powder types will generate significant wear and therefore roller chains are generally not the best solution for abrasive and fine powder types. However, when it comes to very abrasive products or applications for which chain lubrication is not an option, Simatek Bulk Systems offers bearing suspended buckets. With these buckets the wear on the roller chain is basically eliminated.The closed and lubrication free bearing construction generates less friction and has a documented 40% power consumption reduction To document the effect of conveying with a Forced Feeding System, clients are offered a free test run of their product in the Simatek Bulk Systems test center. ■

In traditional pendulum bucket elevators the buckets are suspended between parallel roller chains. However, certain powder types will generate significant wear and therefore roller chains are generally not the best solution for abrasive and fine powder types. However, when it comes to very abrasive products or applications for which chain lubrication is not an option, Simatek Bulk Systems offers bearing suspended buckets. With these buckets the wear on the roller chain is basically eliminated.The closed and lubrication free bearing construction generates less friction and has a documented 40% power consumption reduction To document the effect of conveying with a Forced Feeding System, clients are offered a free test run of their product in the Simatek Bulk Systems test center. ■