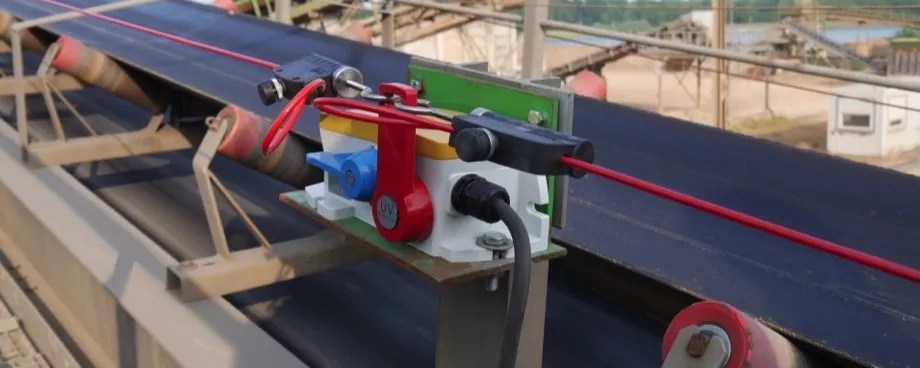

This program includes the extremely robust switchgear of the ZS 92 series for monitoring (belt) conveyors. The series is available in two basic versions: as an emergency pull-wire switch (ZS 92 S) and as an off-track belt switch (ZS 92 SR). In both cases, the user can choose between two corrosion-resistant housing materials: multi-coated die-cast aluminum or high-quality thermoset plastic.

The features of the complete series include a high degree of flexibility. The ZS 92 S can be supplied in various "settings" for adjusting the release lever and release. This means that it can be installed in almost any conceivable position of use and can also be mounted on the rear panel.

The compatible connection dimensions of the new series to other emergency pull-wire switches and belt-alignment switches on the market simplify the retrofitting or replacement of existing devices on (conveyor) systems. In the case of the ZS 92 SR belt-alignment switch, the very simple setting of the switching points for prewarning and disconnection in 5o steps increases flexibility in practical use.

These two switch designs will be demonstrated at Steinexpo in a realistic application situation on a conveyor belt. Also on display will be a very recent product innovation for the protection of bulk material handling systems by "heavy-duty" switchgear: a belt break monitoring system.

Here, a compact ZS 71 type rope pull switch with latching function and a special rope system with rope guides is used. At transfer and feed stations, it is installed transversely below the conveyor belt. If, for example, there is a metal element in the material being conveyed that causes damage when it hits the belt, the ZS 71 is triggered, sends a signal to the system control and thus causes the belt to stop immediately. After the foreign object has been removed and, if necessary, the belt has been repaired, the belt break monitoring can be reactivated simply by pressing the reset button and the belt restarted.

steute at Steinexpo: Stand PC53

■