Take-Up Travel & Fabric Belt Constructiion On Long Belts

It depends on the design optimization process (idler selection and spacing, lubrication, belt speed, loading, ...... ), type of belt tension member fabric construction and type of bottom rubber "low energy loss" compound used.

You say nothing about your design and design criteria including:

a) tonnage - peak and nominal

b) bulk density wet and dry - per tonnage

c) maximum lumps size

d) idler roll diameter

e) idler spacing

f) idler bearings

g) idler trough angle

h) drive system and distribution

i) type of take-up

j) temperature operating range

k) elevations negotiated

l) ......... additionals

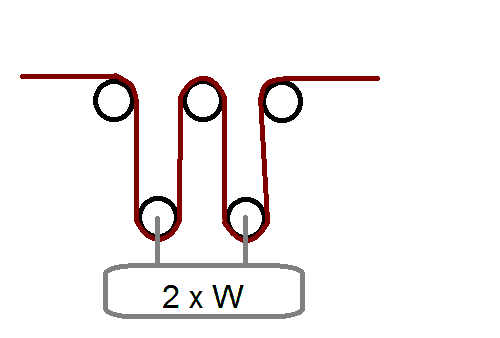

You can split the take-up travel into a fixed section for permanent stretch, spares & splice repair installed in loop, vs. gravity travel in another take-up station for dynamic motios & thermal expansion variations. This should split the motion into two more or less equal lengths. This is a common practice we use for large and long low modulus conveyors. ■

Re: Max. Length Of A Fabric Conveyor Belt

2000 m length is easy for most fabric belt suppliers up to 2000 t/h. Steel cord belts do not need to be used in this size range. Steel cord belts will consume less power. A EP-800 N/mm belt will do fine.

Since you did not nominate capacity and sizes, I made a brief review. ■

Re: Max. Length Of A Fabric Conveyor Belt

Hello Mattsec,

The take-up travel will depend on your tension in the belt due to your design and elastic modulus of your belt. Mr. Nordel listed most of the factor that effect the tension. You can adjust your design to reduce the tension.

Besides, you may use sth. like this arrangemt or sth. more creative.

href="https://forum.bulk-online.com/attachment.php?attachmentid=29261&d=1313577202" title="Name: Untitled.bmpViews: 271Size: 83.3 KB">Untitled.bmp ■

Re: Max. Length Of A Fabric Conveyor Belt

nordell, thankyou for your detailed response when I have provided little detail. I was intensionally vague as I was looking for a general answer as I am very new to conveyor design and have only been exposed to stockyard Iron Ore conveyors doing 12500tph-16000tph where fabric belts are not even considered.

But FYI:

tonnage: 370tph (nominal), 600tph (peak)

belt width: 1200mm

bulk density: 2040kg/m^3

max lump size: 350mm

idler roll diamter: as required but probably 178mm

idler spacing: 1m (carry), 3m (return)

idler bearings: as required

idler trough angle: 45deg

drive system: probably WRIM (probably 6 pole) at head pulley

take-up system: horizontal gravity take-up at tail end

temperature range: 0 to 55 deg celcius (outback Australia)

possible conveyor lengths and lifts: 810m length and 45m lift, 1070m length and 14m lift (these are the most extreme options at present)

Your suggestion of using 2 take-up stations is very interesting. In my situation however, my thinking is that is would be quite an expensive option for a conveyor system with such a small capacity (such as mine). Do you (or anyone else reading this) have any thoughts on this?

Thanks. ■

2 Take-Ups

Expensive? No. The tail pulley can already act as one or both. You just need to install a track system to maintain tail pulley alignment for the range of movement.

Your conveyor design is less than ideal. Not offering an alternative, I still comment on size of lump being way too large for the km transport. You only need the exessive width because of the hugh lump.

The 45 degree trough is also not in character. Try 35 degree. Also 178 mm diameter idlers are not needed. There is insufficient roller pressure to consider their benefits. A 3 m carry x 6 m return idler spacing would be more like a modern design.

Wound Rotor motor? Why not a simple primary voltage starter or simple fixed level fluid coupling when you are considering $$$$? ■

Re: Max. Length Of A Fabric Conveyor Belt

A 900 mm wide belt is more than ample. However, we do not design within this forum. ■

Max. Length of a Fabric Conveyor Belt

Maximum practical length of a fabric conveyor belt

Hi all,

I am in the process of designing conveyors of length 100-1000m for a study. Fabric (PN) belts are preferred but the client requires a minimum take-up travel allowance of 2% of belt length. So, this means a take-up travel allowance of 20m may be required. Is this practically achievable or should steel cord belts be used? Is there a practical limit to the take-up travel length (and hence, conveyor length in this case)?

Note that a horizontal gravity take-up system is preferred.

Note that the system capacity is relatively low so there is no issues with belt tensions.

Cheers. ■