(From the archive of ”bulk solids handling", article published in Vol. 34 (2014) No. 4 , ©2014 bulk-online.com)

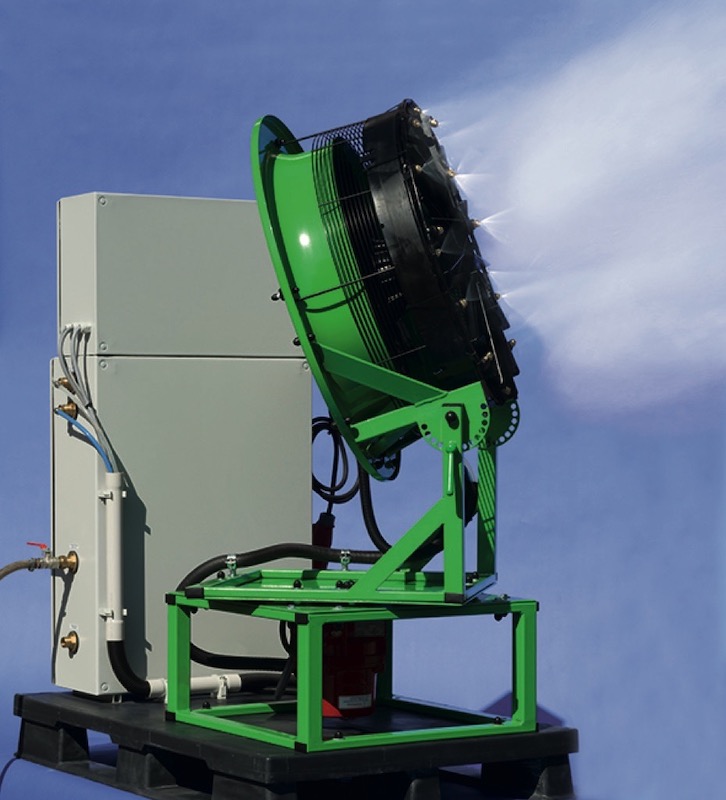

B+Ws Naltec-system fights dust and odour problems in a simple way. Special nozzles generate an artificial fog that binds the dust particles. The fog producing units can be supplied as mobile, semi mobile or stationary systems, or autarc units with water tank and power generator. Installations can run completely automatic. A turnkey solution can be integrated in each existing customer system.As a mobile unit, the system allows for flexible and space saving implementation. It is also suitable for operation during winter period _ a heating system can easily be included. All necessary aggregates like the control unit, pump and tank, as well as an adjustable ventilator, with specially attached nozzles, are combined to form one compact unit.Applications of the water fog system are manifold. It can be used whereever the fine mist can achieve an effect, e.g.:

-

For the Suppression of Industrial Dust

The fine droplets created by the Naltec system easily join with free flowing dust particles in the air. Due to the increased weight, the dust particles sink quickly onto the material-flow instead of being carried away by the air. In most cases, an increase of dampness of approx. 0,1 - 0,5 % (weight) is sufficient to bind the fine dust to the material-flow.Fields of application are, in particular, crushers, belt transfers and screens in the bulk material handling and recycling industries, or where silos and bunkers are fed by belt conveyors, wheel loaders or trucks.

-

For air and material humidification

Due to the fine droplets generated by the system, the desired amount of humidity is quickly reached. Air humidity can be increased to a maximum of 98 % relative humidity, without causing a downpour of water. Using public drinking water, a hygienically harmless humidifying is possible.

-

For gas and material cooling

Due to the fast evaporation of the droplets an adiabatic cooling – especially in production halls during hot summer periods – can be achieved. Further areas of application are gas and material cooling.

-

For odour elimination

The same spraying technique is used for combatting of organic odours, amine and mercaptan treating as well as mixture of the same. By using B+Ws enzymatic additive “Resorbb” the odour molecules will be quickly biodegraded and won´t be covered by other smells. This enzymatic odour elimination is applicable in the field of waste disposal, composting plants, waste water treatment etc.

-

Encrusting of Surface

Here the water is metered to a polymer, which ensures that the surface of driveways, stock piles etc. is crusted. Through the crusted surface no dust plumes or wind drifts can occur. This way, environment and workers are protected from dust.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2014.

| About the Author | |

| Georg BuddenkotteManaging DirectorB+W Gesellschaft für innovative Produkte mbH, Germany |

■