(From the archive of ”bulk solids handling", article published in Vol. 35 (2015) No. 4 , ©2015 bulk-online.com)

During the development of the new steel – apron conveyors system SZB 250 the known requirements of the cement plants were reconsidered and, based on the existing experiences, new solutions produced. The cement plants’ most significant requirements are the following:

- Efficiency

- Rigidity and

- Applicability for inclined conveyance.

Keeping these main features in mind a modular design was developed which provides numerous alternatives.The efficiency is governed by availability, durability and maintenance costs of the steel-apron conveyor system. During the design phase of the new conveyor special attention was paid to these features.Three different modules are the basis of the SZB 250 apron conveyor: conveyor cell, roller and chain with their common interface at the attachment point. This interface point is dimensioned in such a way, that it is applicable for all dimensions of rollers and chains thus drastically reducing the diversity of parts. This common interface point is easily accessible, essentially alleviating maintenance and servicing.Due to weight limitations the stability of the conveyor may not be achieved through extensive material usage, but rather through constructive measures which are aimed at decreasing the level of strain of the apron conveyor system. These constructional measures include:

- short lever arms

- self-supporting conveyor cell system

- wide base for the fixation and

- framework construction for the conveyor cell.

During inclined conveyance of hot materials the apron conveor is subjected to especially high demands regarding

- leak tightness

- wearing performance and

- dead load.

Here the SZB 250 is believed to set new standards.

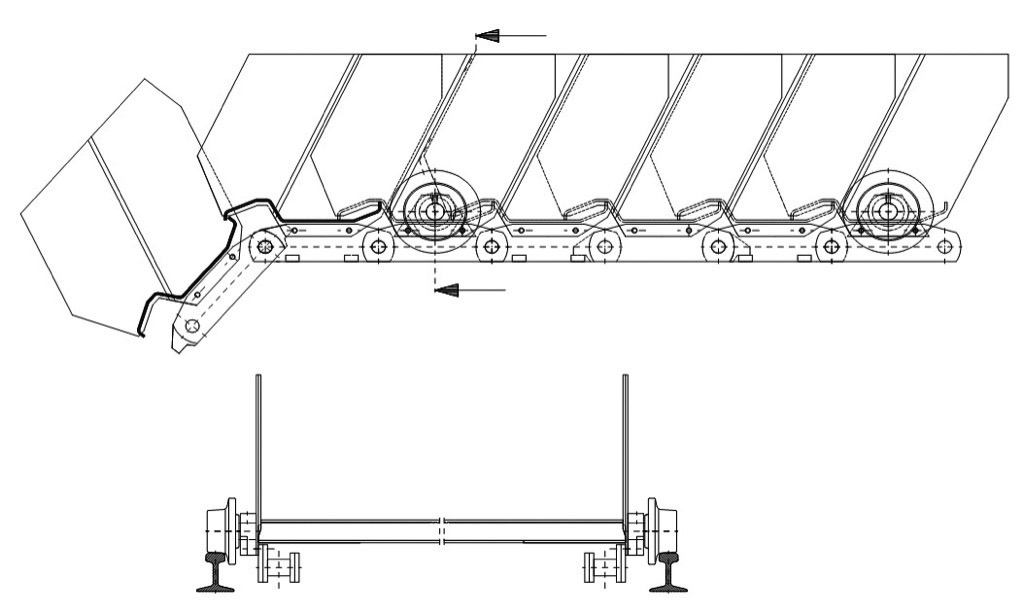

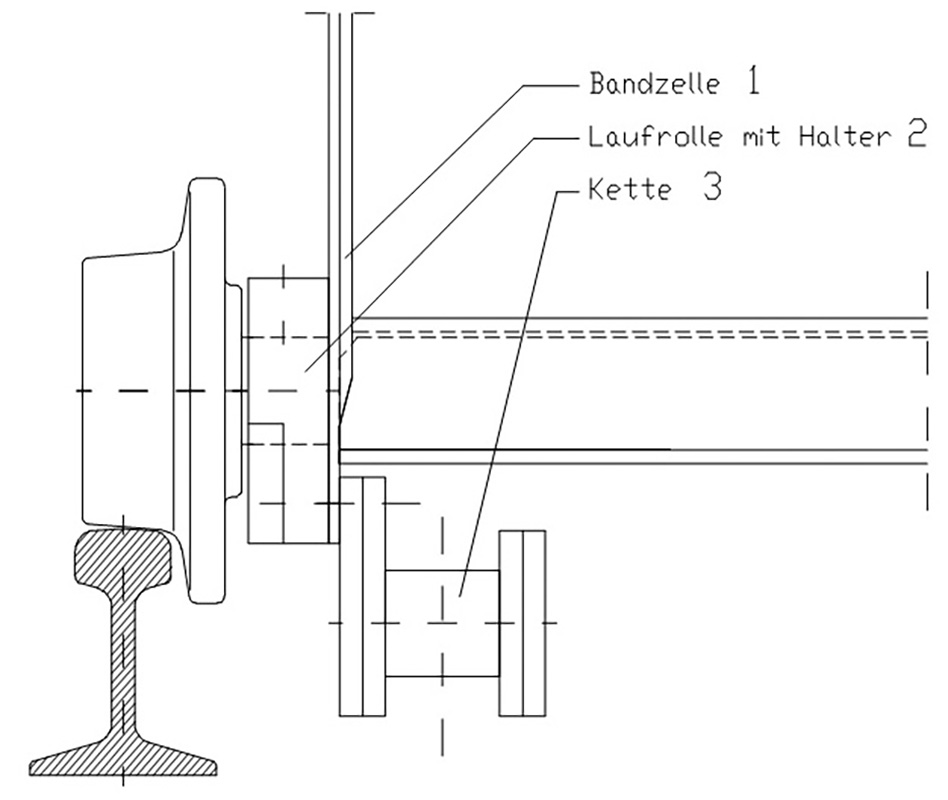

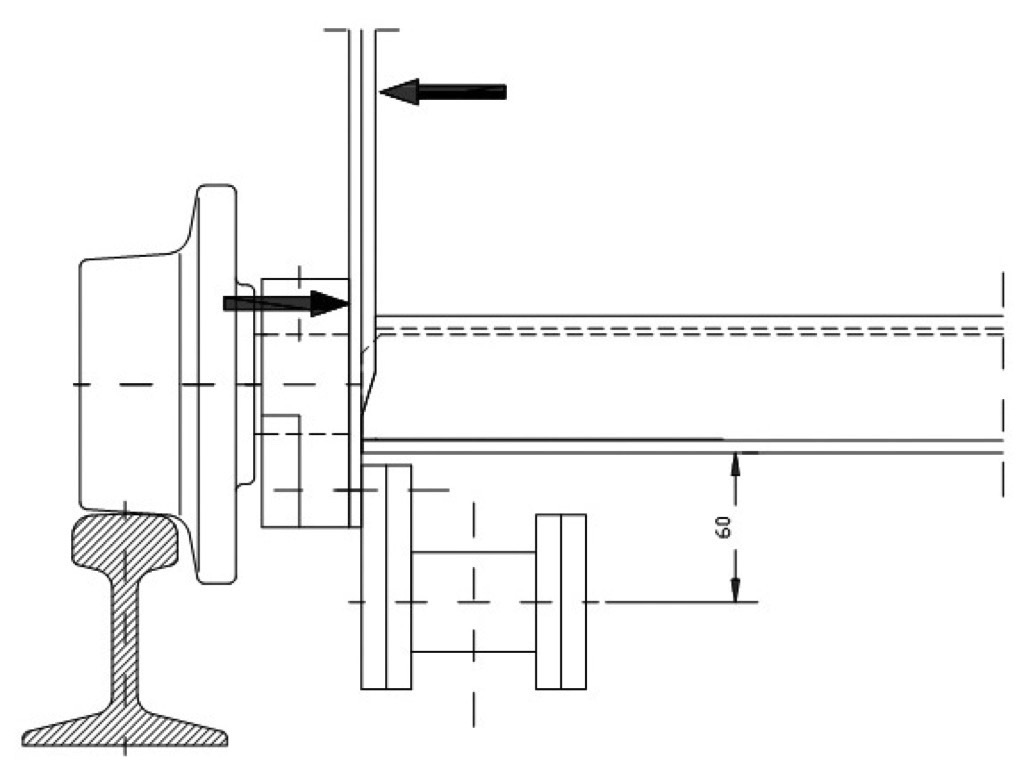

Fig. 2 presents the longitudinal and cross section of the steel – apron conveyor SZB 250 where the basic assembly and operting mode is visible, whereas Fig. 3 shows the three modules which form the conveyor:

- Pos. 1: Apron conveyor cell

- Pos. 2: Roller with retainer

- Pos. 3 :Chain

Fig. 3: Elements of an apron conveyor: 1 - Conveyor cell; 2 - Roller with retainer; 3 - Chain

|

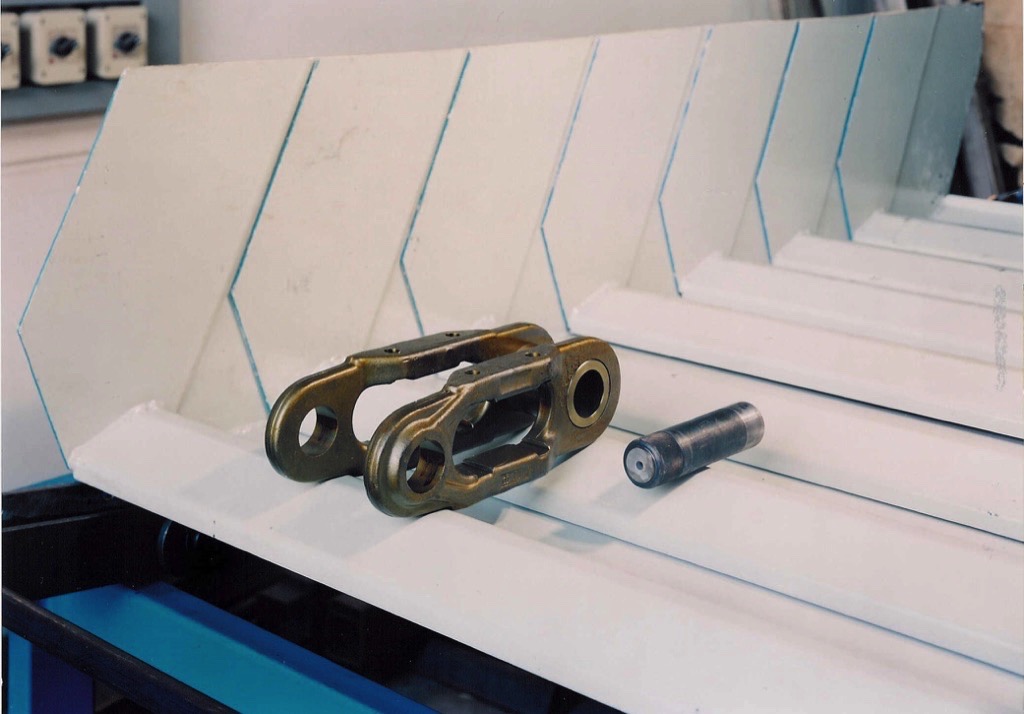

Fig. 4: Elements of an apron conveyor: conveyor cells and chain

|

These modules merge at the attachment point. This merger point is the same for all variations of the apron-conveyor, so there is no dependency with regard to the size of either chain or roller. A roller change is very easy and can be performed with simple tools due to the good accessibility.This alleviates preventive servicing and maintenance of conveyor system thus to the conveyors high availablility. The possibility to fix a roller on every conveyor cell impressively substantiates the modularity of the system.The stability of the apron conveyor depends not only on the forces exerted by the weight of the transported bulk good, but also by the way the flux of force is transferred to the chain.

The conveyor cells of the SZB 250 are self-supporting and so they don’t need to be underpinned by pins and dogs (see Fig. 5), thus improving the durability of the chain.The conventional fastening of the chain under the cells floor section using angular butt straps induces an additional moment due to the distance between chain and roller and the weight of the chain element. This moment spawns an additional load spectrum, which must be absorbed by the cells’ floor section. Directly fastening the chain to the roller retainer eliminates the load-arm and the additional load spectrum and increases the cells stability.

The transported material in the apron- conveyor exerts varying pressures against the floor section according to the differing load factor. The load of the rollers will exert a counteracting force which avoids the bending of the cell floor section, (Fig. 6). Also, the load upon the welded joint between side and floor panel will be greatly reduced.Further constructional features are:

- The roller retainer constitutes a strong frame between side and floor panel.

- The overhang of the side panel is evenly split between sides of the floor section.

- Due to its short length the roller axis is very bending resistant and therefore contributes to the systems stability.

The bolted connection between the floor section, roller and chain won’t come into contact with the bulk material and so won’t be exposed to special thermal stress.As an apron conveyor can not be built like a continuing belt conveyor, but rather of many overlapping single cells, the leak tightness and wear resistance are of particular importance. Here the new apron conveyor is supposed to set new standards.

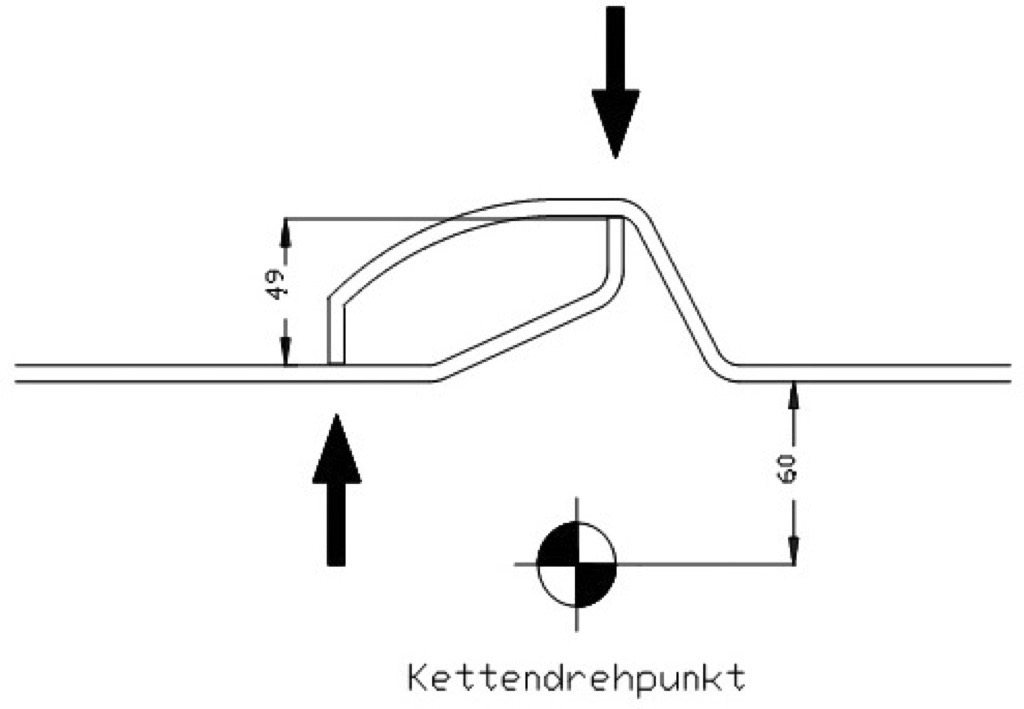

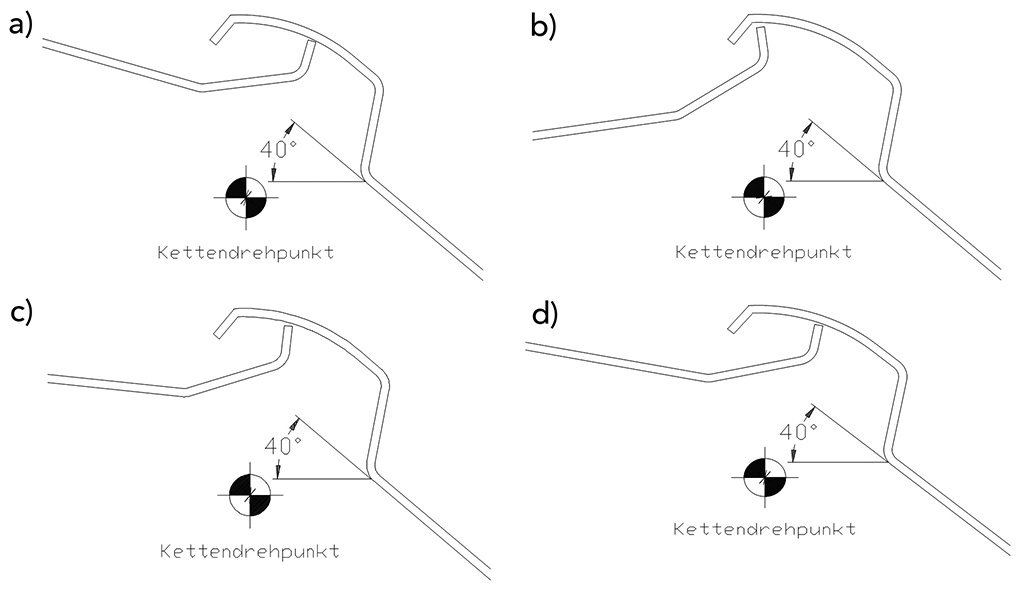

As regards the topic leak tightness it can be summerised as follows:

- The geometry of the hinge is optimally adapt to all chain sizes (the pivot point is the same for all chain sizes).

- The sealing properties are optimally adapted to all sprocket dimensions. (Even on a sprocket no material remains in the sealing chamber).

- Self cleaning of the sealing chamber.

- No risk of destruction through material deposits on the return strand.

| About the Author | |

| Norbert KleinerüschkampFeld-Kleinerüschkamp GmbH, Germany |

■