All too often, plant operators don’t realize there is a problem with their belt conveyor system until production is halted and their operation isn’t producing. Those unexpected periods of downtime can lead to some major problems, including the inability to fulfill customer demands, worker downtime, overtime pay when the plant employees return to work to fulfill those demands, and even safety issues as a plant struggles to get back up to speed. Worst of all, it affects the plant’s bottom line.

The question is, “Why don’t more plants audit their equipment to detect potential problems before they lead to costly repairs and downtime?” Bringing in a third party who can assess the belt conveyor system and provide operations with the feedback needed to keep the plant running could be the difference between having a record-breaking year and a backbreaking year.

Why perform an Audit?

There are a lot of reasons to have someone come in and perform an audit on an operation. a fresh set of eyes looking at the system from an outside view is key, especially since resources have been reduced at many operations and worker safety is still a major concern. plus, the number of violations a plant can accumulate after a visit from an inspector can often result in unexpected downtime and costly fines – another reason regularly scheduled audits are so important.

Owners and operators that are around the conveyors every day may not notice the slight changes in the system, while a fresh set of eyes can identify issues. Instead of waiting for something to go wrong, the auditor can help address the issues proactively, saving time and money in unscheduled downtime.

Safety issues are also a major concern when it comes to audits. While the safety of workers is most important, the amount of violations a plant can accumulate after a visit from an inspector is also important.

If nothing else, an audit can help keep the equipment running longer. Simple maintenance tasks that may have gone unnoticed can be identified and addressed by the operation, or components can be replaced that will make equipment run more efficiently.

What makes a good Audit?

While each plant is different, the elements of a good belt conveyor audit are the same. And the No. 1 rule of thumb is to look at the conveyor system holistically.

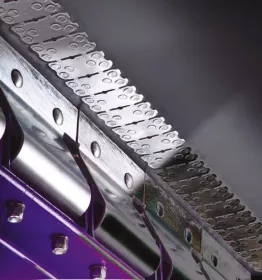

While each product in a conveyor system is a separate component, the entire system should be evaluated as a whole to ensure that everything is compatible. For example, if the fasteners and belt cleaners aren’t compatible or the system isn’t center loading, the operator could have a serious problem.

Focusing on system solutions, as opposed to simply focusing on replacing specific products, is also key to a good conveyor audit. Whoever walks the belt conveyor line needs to identify all of the issues they find, not simply the issues that they can fix with a product or service.

Auditors find plenty of problems that they don’t specifically have a fix for, but they can still be identified and pointed in the right direction. If it looks like there may be a structural problem, for example, an auditor may suggest contacting an architect for advice.

The point of an audit is not to simply identify problems, but to identify the root cause of those problems. Simply telling an operation that the belt is dirty and suggesting a product to “fix” the problem is not a best practice when it comes to audits. An auditor should tell the operation why the problem is occurring and why the solution he/she is suggesting will work for the system.

Get the Facts from the Audit

As part of the audit plan, the auditor should visit the operation and evaluate the entire belt conveyor system. These specialists should be knowledgeable experts with strong technical skills and years of hands-on training with belt conveyor systems and components.

The auditor should identify problems that may immediately pose risks to workers or equipment. The auditor should also record his/her findings and return to the operation with a complete presentation on the system, identifying immediate needs, and suggested future fixes.

Operations should look for an auditor that provides a complete report on the findings, identifying the issues and the importance of fixing each issue. An auditor should identify which fixes are immediate and which fixes are recommended for the future so that an operation can develop a timeline for these adjustments.

Top three Audit Findings

While damaged components and safety issues are always big concerns, the top three issues identified in a belt conveyor audit are carryback, spillage, and mistracking. These issues may seem like simple things that should be noticed by those working at the plant, but this isn’t always the case.

While workers look at the conveyors every day and will notice the big issues; they often overlook the everyday issues or any subtle changes. For example, a pile of debris sitting under a conveyor may seem commonplace, when the reality is that the right adjustment or equipment could drastically decrease or eliminate that problem.

Over time, carryback, spillage, and mistracking can cause serious problems for an operation’s belt conveyor system. Although these may seem to be everyday issues, solutions are available and are integral to an operation’s success.

The most important Part

The one commitment operations have to make when deciding to perform an audit doesn’t involve scheduling the time for someone to come out to the plant. It doesn’t even involve having someone available to walk the auditor around the plant during the audit. The most important part of the audit is actually addressing the issues.

Audits should be performed at least once a year. And a true audit cannot be performed without all of the belt conveyors running. Part of an audit, after all, is ensuring that all of the components are compatible, and compatibility can’t be reviewed unless the auditor sees the parts interacting with each other. Following through with the audit results also involves finding local experts available to implement and maintain these systems and solutions. A quick discussion with a local distributor can identify what resources are available to help an operation’s belt conveyor system run more efficiently.

■