(From the archive of ”bulk solids handling", article published in Vol. 32 (2012) No. 3 , ©2012 bulk-online.com)

Even if high industrialised countries like Germany are discussing a long term oriented exit strategy for coal based power generation in order to cope with the challenges of greenhouse gas emissions, coal will definitely remain to be the most important source of fossil primary energy for the next decades on a global base.The economic development in China, India and other emerging countries is based essentially on the use of coal for power generation [1]. Therefore the development of new technologies for the handling of coal can contribute something to make the use of coal more efficient and sustainable. This article concentrates on automation trends in large scale coal handling systems based on current and future ABB projects.

From Mine to Plant

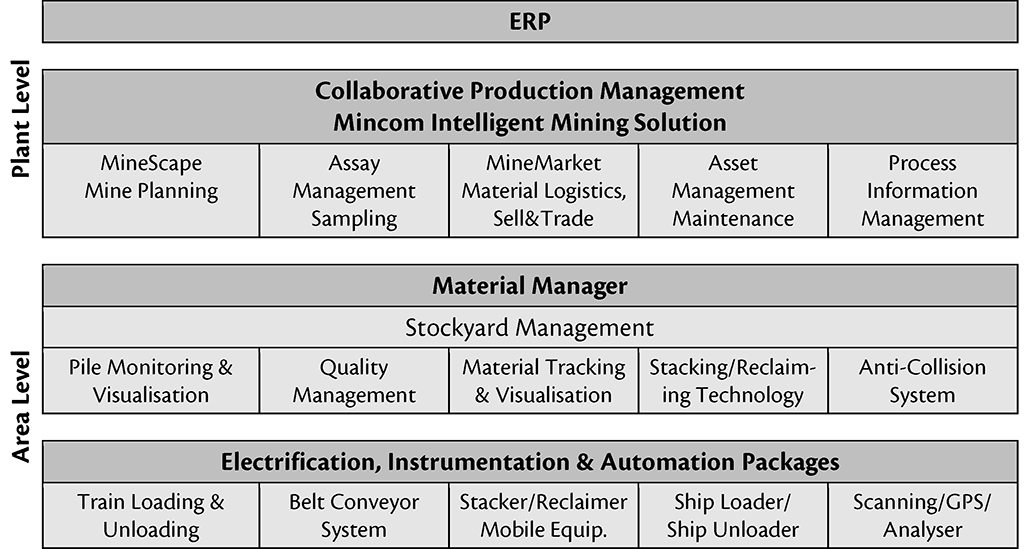

Coal handling systems are an integral part of a complete material flow and quality management system.The increased degree of efficiency of modern coal power plants calls for an integrated coal handling management system in order to secure the coal supply in the requested quantity and quality. In order to cover these requirements ABB has developed a modular management system as shown in Fig. 2.

With the acquisition of Mincom, ABB will seamlessly integrate the Mincom Intelligent Mining Solution (IMS) into an overall production mine and material handling system.The production management level includes the tools for managing the mine, haulage and trade process in regard of fulfilment of contracts (quantity and quality), production management, maintenance and asset management. This level provides also necessary interfaces to ERP systems like SAP and others.The Stockyard Management System (SMS) which will be described in more detail in the following sections enables a fully automated operation of the whole stockyard from a central control room and consists of the following modules:

- Pile Monitoring and Visualisation

- Material Tracking

- Quality Management

- Autonomous Stacking/Reclaiming

The local automation level covers all basic control functions, mostly implemented on the stockyard equipment itself. It includes instrumentation, electrification and automation scope on a local PLC for operator controlled stockyard machines.This system can be customised to the needs of determined projects like:

- stockyard systems for lignite power plants (connected with the mine by rail or an overland conveyor system),

- in-plant coal handling systems, and

- export or import coal terminals with ship and train loading and unloading.

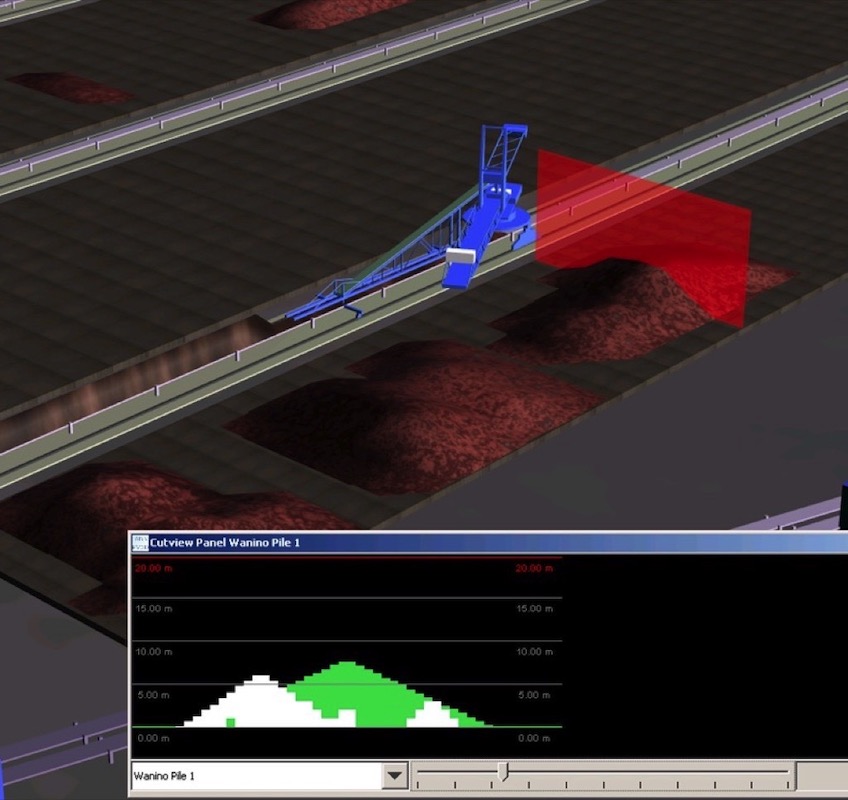

Stockyard Management

To achieve a fully automated operation from a central control room the operator must know at any time how much coal, in what quality is located where. It has to be traceable anywhere, even in a surge bin, on a belt or on the stockpile.These requirements can be met by an exact database of material quality information in the transportation and stockpile model which monitors online the material flow. The necessary input for the model is delivered by laser scanners and positioning systems mounted on the stockyard machines which allow autonomous operation of the machines as well.The scanners can provide surface information of their environments which will be used to recalculate the model. This solution enables a nearly real time update of the pile surface even after material movements due to environmental influences like storm or heavy rain or due to the use of mobile machines like bull dozers.

Stockpile Visualisation

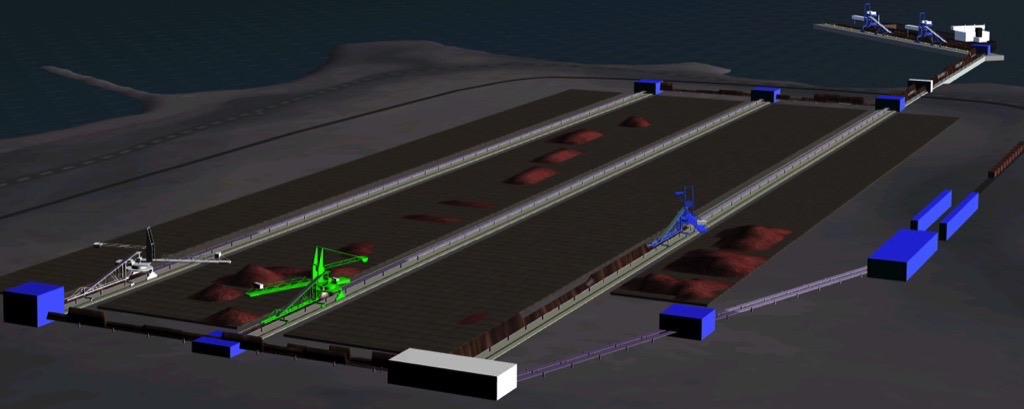

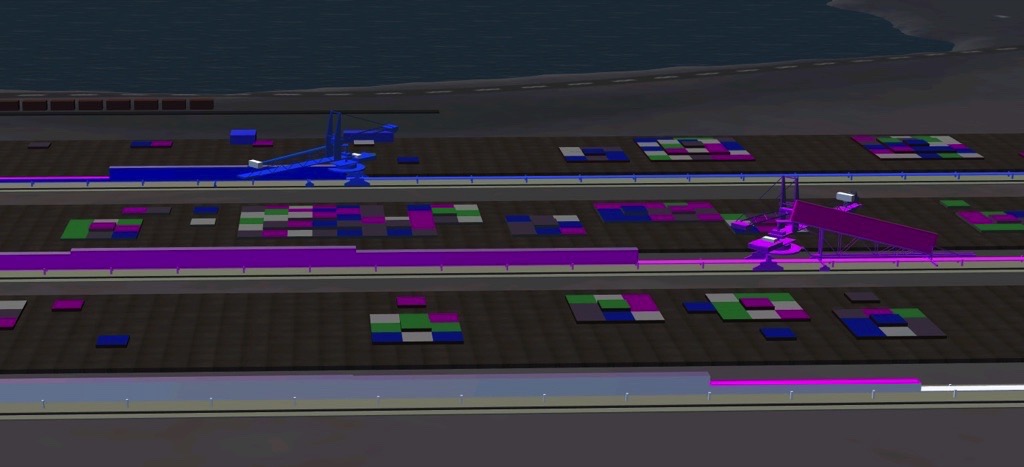

The stockpile monitoring and visualisation module records material movements to and from a stockpile and calculates the material distribution on a stockpile accordingly.The stockpile visualisation module supplies information about the material on the stockpile and its shape as well as the different properties (quality) of the material. Material distribution on the stockpile will be calculated with a computational module based on the information of the module "Material Tracking, Stacking and Reclaiming Technologies" and the 3D laser scanning results.The stockpile visualisation component offers a graphical presentation of the information stored in the stockyard management system in a modern browser technology. The visualisation shows an overview over all stockpiles on the job site. The stockyard can be displayed in 2D or in 3D view, see Fig. 3.

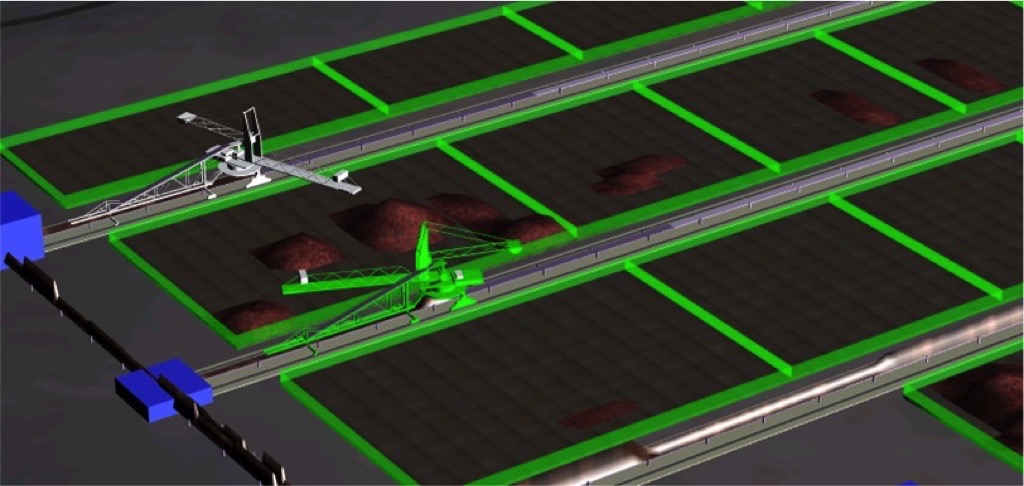

For a detailed analysis of the stockyard it is possible to zoom and turn the view. The view can be adjusted from different view points and separate piles can be selected. Stockpiles can be split into small individual virtual piles. These sections are shown with their borders in Fig. 4. Fig. 5 shows the system's ability to display the properties, as well as slice or cut views of each pile area.

Material Tracking

The module "Material Tracking" supports the operator in monitoring the flow of the bulk material and supplies real time stockpile tracking by tonnage and quality. The main functions are:

- gathering information of material type, quality and its specifications at the inlet of the stockyard,

- monitoring of masses/volumes on the way to the stockpiles via belt conveyors,

- tracking of materials to the discharge point,

- dynamic display of belt load with colour coded material property information,

- balances of input, stored and output material mass/volume, and

- data exchange to overriding MES systems.

The "Material Tracking" module manages the distribution on the stockyard to enable an efficient usage of the complete area with determined coal quality in every stockpile (see Fig. 6).

Coal Quality

An integrated coal quality management system is in particular important in cases where power plants are supplied by different mines with variable coal parameters like:

- calorific value,

- density,

- ash content,

- moisture content, as well as

- content of sulfur, silicon, aluminum and potassium.

Modern generating units need a certain coal quality with tight variations in order to ensure an efficient burning process. Significant deviations can cause slagging processes to the point of unscheduled downtimes of the whole unit with remarkable loss of production.The coal quality parameters can be detected either offline, by drill samples and laboratory analysis, or online, with radiometric methods. For the quantity measurement belt scales or belt volume scanners can be used.Coal quality information (e. g. RFID, bar code, electronic transmission per file, or freight papers) has to be handed over by the supplier or/and can be measured online right away at the loading point and often verified after the coal has been received at the discharge point.The quality can be assured by blending the coal within the mining operation (combination of mining units, shifting heads and coal lines), on the stockyard during the stacking or reclaiming process or in the in-plant storage and feeding system.

Autonomous Operation

The coal can be stacked and reclaimed by various methods in order to provide an adequate treatment of the material and perform the necessary mixing and blending process.The requested quality of the mixing and blending process is ensured by predefined stacking and reclaiming methods like:

- windrow stacking,

- chevron stacking,

- cone shell stacking,

- strata stacking,

- block stacking,

- long travel reclaiming,

- block (bench) reclaiming, or

- pilgrim step reclaiming.

These methods are contained in a control library and can be selected by choice or automatically.Yard machines are running without any local operator and are only supervised by one operator in the central control room. This operation mode has a number of advantages, such as:

- constant and optimised belt load and thus optimised material throughput,

- less equipment wear due to less stress factors (no system overload),

- less faults and damages triggered by operator failures,

- reduced labour costs, and

- energy savings by smooth and continuous operation.

In addition to the warning by the laser scanner and GPS signal (collision between two machines), pile height sensors on both sides of the boom help to avoid collisions between boom and pile. During fully automated operation access to the pile area is restricted to trained people in safe areas only.

Example Project

The development of the above described system is based, aside from other projects, on the experiences ABB gained during the project execution of the automatic operation for the stockyard system of the Schleenhain lignite mine in Germany. The Schleenhain lignite mine feeds the power plant Lippendorf which has a power generation capacity of 2 × 993 megawatts.The stockyard system comprises a stacker with a stacking capacity of 4200 tonnes per hour, two portal scrapers with a reclaiming capacity of 2400 tonnes per hour, each, and the conveyor system including the conveyors from the mine to the power plant. The piles have a capacity of 400 000 tonnes.The stockyard system as well as the belt conveyor systems are operated fully automatic by an ABB Advant OCS system from a central control room and have been in operation since 1999. Recently ABB executed a complete upgrade to an ABB System 800xA.The experience has shown that an integrated fully automated stockyard system can contribute to a safe and efficient coal supply of modern power plants.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2012.

References:

- Annual Report 2010 Verein der Kohleimporteure e.V.; http://www. vereinkohlenimporteure.de/wEnglish/index.php?navid=4.

| About the Author | |

| Peter MühlbachBusiness Development MiningABB, Germany |

■