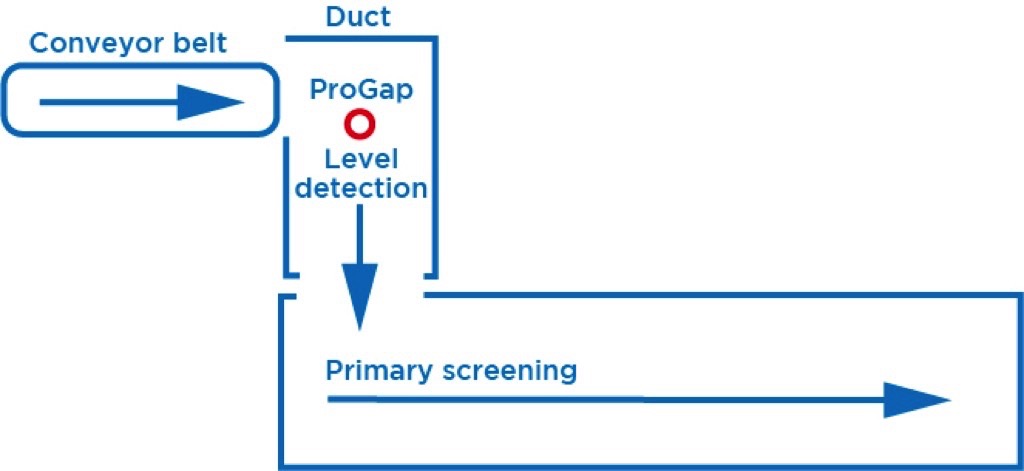

ApplicationDuring the extraction and processing of basalt and lava stones of varying sizes in the plant of a German natural stone company, the first screening stage is occasionally clogged. The material is fed to this screening plant by a conveyor belt system via a feeding chute. In some cases the clogging leads to a congestion and jamming of the material in the feeding chute. If the congestion reaches the upstream conveyor belt, there is a risk that it will be damaged. This often results in costly and time-consuming production downtimes.

Process data

- Costumer: Mineral company

- Material: Stones (basalt and lava)

- Installation: Feeding chute behind conveyor belt

- Function: Protection of conveyor belt

Solution

The ProGap S with filling flow detection is a universally and flexibly applicable filling level sensor based on proven microwave technology. In this application, the ProGap S is used to detect the accumulation of rocks in the feeding chute between the conveyor belt system and the first screening stage.When a critical level monitored by the ProGap S is reached, the conveyor is (initially) stopped. The screening unit generally continues to run and thus usually dissolves the built-up accumulation.If, however, the sieve is not able to remove the accumulated material within a certain period of time, an alarm is issued to the plant personnel and the clogged sieve can be cleaned manually.

Customer benefit

- Prevention of damage to the screen and conveyor belt in the event of a material congestion.

- Reduced number of shutdowns, less production downtime due to blockages.

■