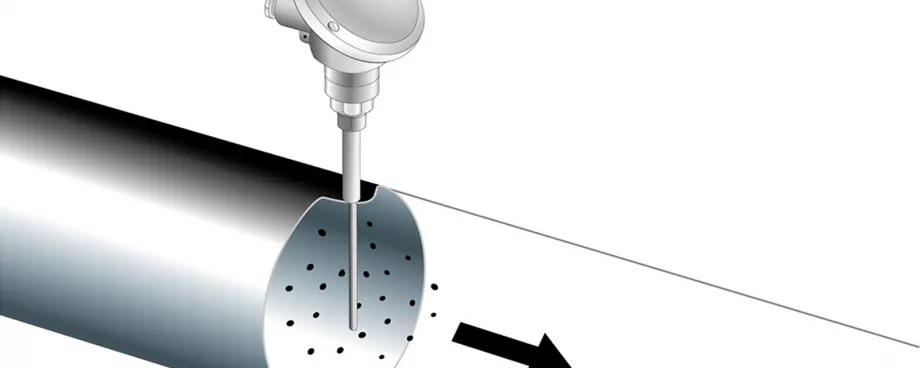

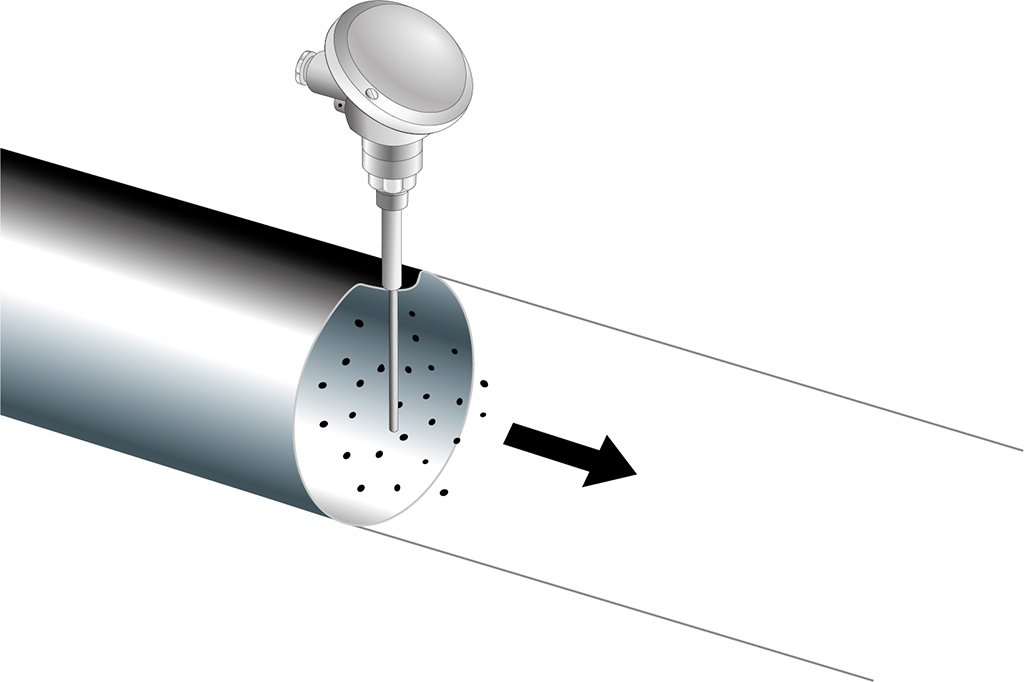

During normal operation specified quantities of starch are fed into the system, filtered and transported further. If the filters in the fine screen become blocked, the material continues to be fed in, but removal of the material can no longer be ensured. In this case the fine screen becomes too heavy and the increased imbalance causes the fibre glass frames to break. This creates a considerable amount of dust. In such cases the operation of the fine screen is interrupted by the installed AirSafe (3).

Process dataCustomer: food manufacturerMaterial: starchInstallation location: screening plantFunction: causes the system to shut down if material clogs up the adjacent fine screen.

SolutionIf the filters in the fine screen become clogged up, the fine screen overbalances, breaking the fibreglass frames used for mounting the screen.Such a breakage creates a considerable amount of dust. In this case AirSafe is activated and sends a signal to the screen assembly‘s controls causing them to shut down. This prevents any further material from being transported and the system comes to a standstill. In addition to the areas of explosion protection and employee safety the area of system protection is another typical field of application for AirSafe.

User benefit• simple system stop without a time delay• protection of system safety and prevention of further system damage ■