(From the archive of ”bulk solids handling", article published in Vol. 36 (2016) No. 5 , ©2016 bulk-online.com)

Open-pit mining often relies on excavators and trucks for the extraction and subsequent removal and transport of the material. Diesel fuel is the standard energy source used to run the machinery. This mining method has several disadvantages, for example high operating costs (for fuel, personnel, accommodation, travelling and maintenance), a high safety risk (caused by the effects of the weather or by the human factor) or a heavy burden on the environment (caused by CO2 and noise emissions).Slope angles in open-pit mines can be as steep as some 70°, which is why roads for trucks in open-pit mines are usually laid out in terraces. Ropecon offers an alternative way of organising the transport of material in difficult terrain.The system was developed by Doppelmayr Transport Technology specifically to transport solid bulk material of all kinds. It is perfectly suited for transporting material in and over difficult terrain, as it can traverse obstacles such as rivers, buildings, gorges, or roads without any problem whatsoever and will easily overcome such steep conveying sections of up to 70°.This system transports the material on a flat belt with corrugated side walls. The belt design originates from vertical conveying, where it has been used for decades. The flat belt performs the haulage function and is driven by, and guided around, a drum at both ends.The belt is mounted on axles arranged at regular intervals to support it. Running wheels are fitted to both ends of the axles. These wheels run on track ropes with fixed anchoring and guide the belt. The track ropes are lifted off the ground on tower structures.Due to the rope support structure distances between the towers can be several hundred metres long, and Ropecon will affect neither the terrain between the towers (Fig. 1.) nor roads, trucks or other infrastructure.

Depending on the steepness of the terrain, the Ropecon belt can be fitted with cleats in order to stabilise the material on the belt. These components, too, originate from vertical conveying and allow for a transport of the material over inclines of up to 90° (see Fig. 2.)Ropecon can also be extended in line with the axis of the conveyor belt. As the open-pit mine grows and changes, the loading or discharge point can be adjusted flexibly along that axis to meet the new requirements. Additionally, under certain conditions, it is possible to discharge the material at several discharge points along the axis of the conveyor belt.The greatest possible grain size along with the maximum conveying angle will determine the width of the flat belt, the height of the corrugated side walls, the height of the cleats and their spacing. Subject to certain conditions, Ropecon can handle lump sizes of up to 1000 mm. In this case, there is no need to crush the material prior to transporting it out of the pit.Conveying capacity, conveying speed, possible nominal breaking strength and required nominal breaking strength of the flat belt are the factors which determine the greatest possible vertical rise. The conveying speed is usually limited by the maximum grain size. High-strength flat belts with steel cord tension elements and nominal strength of more than 7800 N/mm are state-of-the-art. The necessary nominal strengths are determined in accordance with the provisions of German Industrial Standard DIN 22101:2011-12.Where conveying capacities are lower and grain sizes smaller, Ropecon can overcome differences in elevation of up to 1200 m.

The system is characterised by easy maintenance: all moving parts such as, e.g., the running wheels are attached to the belt and therefore keep passing through the stations, where they can be serviced without a problem. The system can also be fitted with an inspection vehicle to facilitate inspection along the line (see Fig. 3). Consequently, only a small number of personnel is required for operation and service.In times where an ever greater emphasis is placed on reducing the environmental footprint, open-pit mining, too, should look into methods which will actually save resources. When it comes to transport, Ropecon can be an attractive alternative.

Example: Ropecon in Open-Pit Mining:

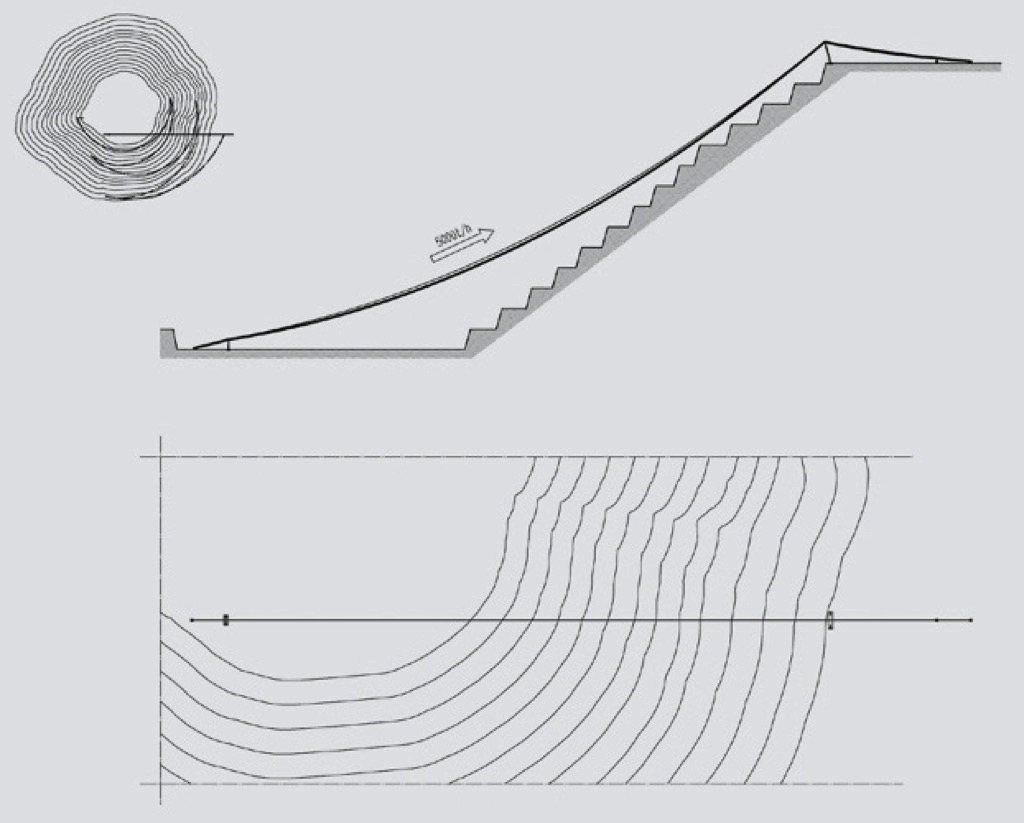

For the following example we have assumed that a mine operator must transport 5000 t/h of ore from a loading station at the bottom of an open-pit mine to a discharge station located outside the mine. A Ropecon system spans a terraced open-pit mine over a length of 486 m and a vertical rise of 350 m in one long stretch (see Fig. 4.).It does not contact either of the terraces so that they can be used by the mining vehicles as before. The conveying track runs in a straight line and can be chosen independent of the geological conditions between the ground contact points. Ropecon can be loaded and emptied just like any conventional belt conveyor, e.g., via chutes.

| Material Conveyed | Copper Ore | |

| Density | 1.9 t/m3 | |

| Grain size | <350 mm | |

| Conveying length | 945 m | |

| Vertical rise | +350 m | |

| Conveying capacity | 5000 t/h | |

| Conveying speed | 3.9 m/s | |

| Belt width | 1600 mm | |

| Belt strength | ST6000 14T/9T-Y | |

| Side wall height | 320 mm | |

| Cleat height | 280 mm | |

| Cleat spacing | 600 mm | |

| Electrical drive output | 5900 kW | |

The drive unit for the conveyor system in our example is positioned outside the mine (right margin of Fig. 4). We have assumed a transport route of approx. 5.1 km between the loading and the discharge point if the material is to be transported by trucks. With a maximum vehicle load capacity of 363 t, approx. 15 trucks will be necessary to achieve the required conveying capacity. Ropecon will achieve the same conveying capacity at just 60 % of the costs.

■