“We had been operating with airpads in our 144-ton silos that store white cement powder and calcium carbonate used to make our thin set adhesive and grout for tile floors,” observes Plant Manager Mike Dulin. The result, he adds, was leaking of the fine powders around the air pad installations; poor aeration for the constant flow needed for the blending and packaging process; plus, weekly consumption of seven hours’ production time for screen media cleaning and replacement.

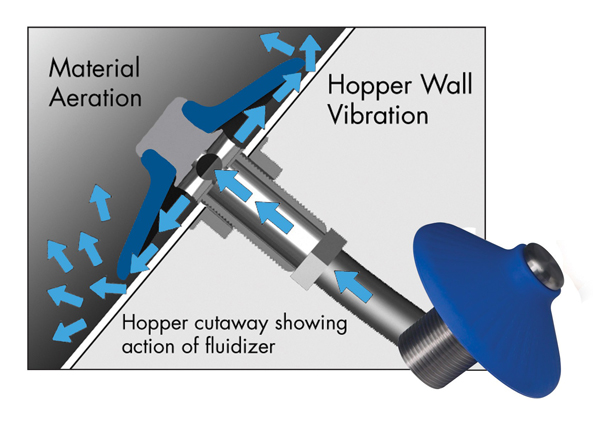

Solimar Pneumatics, originator of the disk-type pneumatic fluidizer, had the answer for Dulin’s operation: Installation of an array of 4-in. diameter silicone disks in the bottom of each silo. The disks provide uniform flow and discharge of dry bulk materials through aeration and hopper wall vibration. They prevent bridging, rat holing and compacting in storage silos, dust collectors and weigh bins. Compressed air provides directional airflow along the silo wall and gentle vibration keeps product flowing with no plugging. The patented disks seal tightly and the durable design will not tear.

Because cutting holes in silos walls is expensive and time consuming, Solimar’s EZ-IN Kits were a natural choice for retrofitting Forpac’s eight silos. The system fits existing airpad openings and features a gasket permanently fixed to the mounting plate. Zinc plated carbon or stainless steel models are available in three styles to fit most existing hole patterns.

Forpac was able to justify the cost for purchase and installation of the aerators in just one week from savings in silo cleaning time and production gains. Solimar engineers helped determine the number and spacing of the aerators to assure proper flow.

“It took about two hours per silo to replace the old air pads with the Solimar fluidizers,” Dulin recalls. After 18 months with the EZ system, he adds, “It’s like the difference between an antique method and a thoroughly modern method of aeration.” ■