In addition, continuing its commitment to providing innovative solutions for customers, Flexco will discuss the future of belt conveyor technology for heavy duty applications in various industries.Visitors can stop by Booth C32314 to learn how Flexco can help operations optimize their belt conveyors. The booth will feature a full-size conveyor, as well as interactive displays to help attendees better understand the features and benefits of Flexco product solutions. Live demonstrations of conveyor rip repair and 45-degree fastener installation using the Flexco Bolt Solid Plate Fastening system will also take place at the booth.This year, Flexco National Accounts/OEM Manager Dick McConnell will be speaking during the educational sessions. McConnell will co-present “Maximizing Conveyor Performance – Industry Standards Versus Real World Application” on Thursday, March 12th from 9:30 a. m. to 10:30 a. m.

Superior Cleaning and Dust Containment

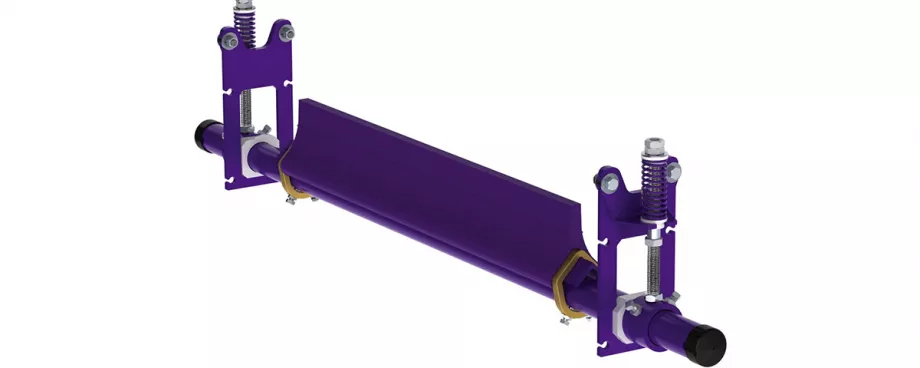

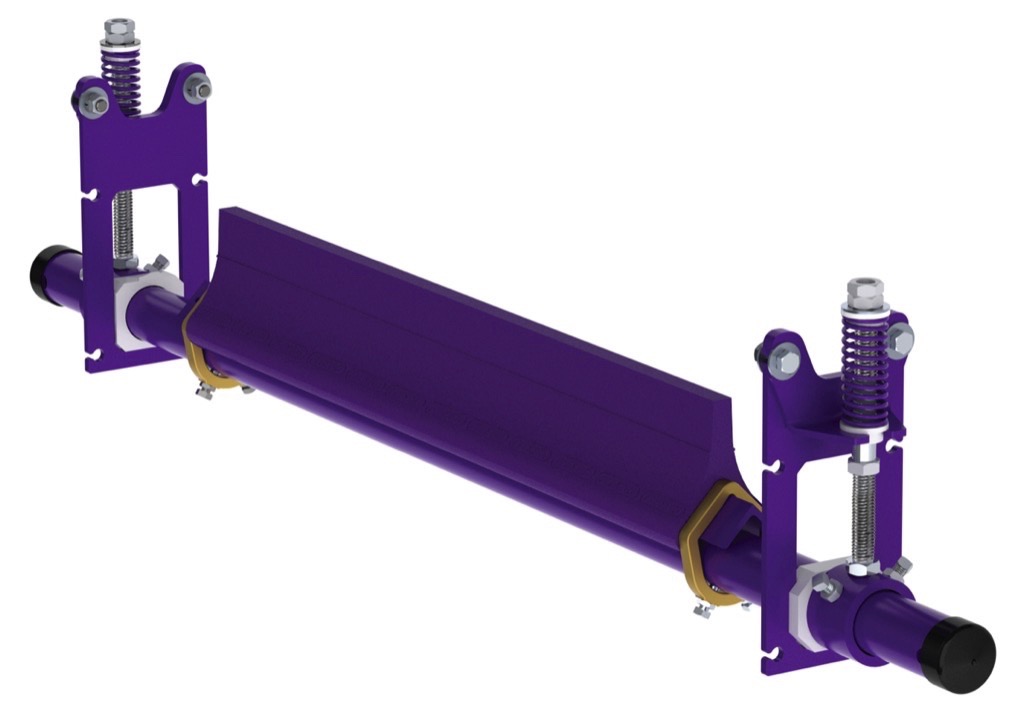

At the booth, Flexco will be showcasing a variety of products designed to increase efficiency and decrease downtime. The Flexco Wash Box is designed to deliver superior cleaning efficiency in applications where the conveyor must be very clean or when head-end cleaning is not enough. Mounted on the return side of the belt, hinged doors are available on each side for easy inspection.The Y-Type Secondary Cleaner, a product that is ideal for use in aggregate applications, will also be highlighted at this year’s booth. With standard and heavy-duty options available, the Y-Type offers multiple blade options and easy maintenance at an affordable price.If you are having dust containment issues at the load zone, stop by the booth for more information on the Flexco Enclosed Skirt System and Dual Seal Polyurethane Skirting.

Safer, easier Installation and Maintenance

As always, Flexco is focused on making installation and maintenance safer and simpler with our maintenance tools. At this year’s booth, we will introduce our new TUG HD® Belt Clamps, which are designed to secure the belt for repair, meeting the most stringent safety test standards. Available in 6 and 8 ton versions, TUG HD Belt Clamps provide even tensioning across the entire belt width for ultimate strength. Modular components allow for increased versatility and portability.The Flex-Lifter Belt Lifter, 900 Series Belt Cutter, and Cordless Electric Belt Cutter round out the group of products designed for safer belt conveyor maintenance that will be highlighted in the Flexco booth this year.Experienced Flexco team members will be available to discuss the entire conveyor system and help attendees identify challenges and ways to increase the efficiency and productivity of their operations. Flexco is able to address almost any conveyor challenge – from slippage and spillage, to mistracking and wear and tear, to safety and environmental concerns. Even after a belt is up and running, Flexco stays involved to ensure that its products are delivering the top-notch performance needed for maximum productivity.Visit Flexco at CONEXPO-CON/AGG 2020, Booth C32314, Central Hall C3-C5. ■