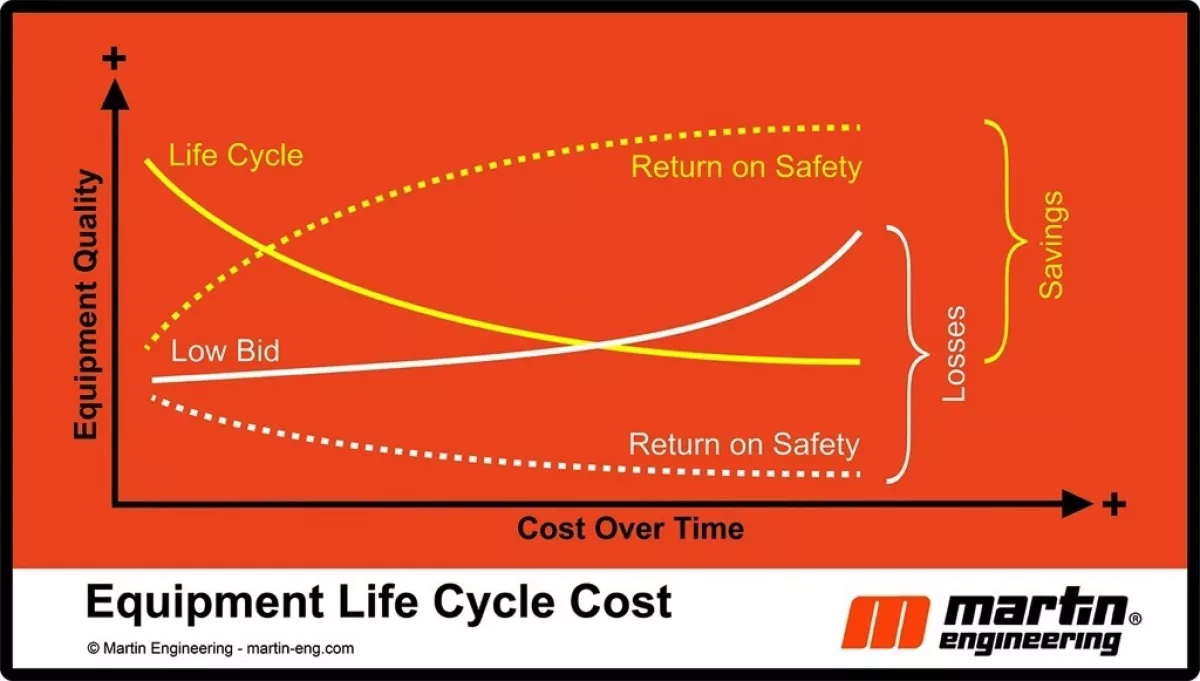

When companies buy on price (Low Bid) the benefits are short-lived and costs typically increase over time. In contrast, when purchases are made based on lowest long term cost (Life Cycle Cost), benefits usually continue to accrue and costs go down, resulting in a net savings over time. Safer and more reliable equipment is easier to service, has a longer life and is less expensive to maintain.

Organizations that embrace safety show significant performance advantages over the competition. The proof is reflected in reduced injuries and greater productivity, along with above industry average financial returns and higher share prices.

Justifying safety investments is greatly enhanced by quantifying what most financial managers refer to as “intangible costs”, i.e., injuries, lost labor, insurance, morale, legal settlements, etc. However, managers and accountants have been trained to think about saving direct costs to justify investments.

When conveyors don’t operate efficiently they have unplanned stoppages, release large quantities of fugitive materials and require more maintenance. Emergency breakdowns, cleaning of excessive spillage and reactive maintenance all contribute to an unsafe workplace.

Safety Pays

Numerous case studies revealing the positive relationships between safety and productivity are backed up by organizations that gather global statistics on accidents and incidents. The simple formula for return on investment (dividing savings by cost) does not capture the potential savings from safety investments. Several organizations provide detailed and regional statistics on the cost of accidents.