(From the archive of ”bulk solids handling", article published in Vol. 35 (2015) No. 2 , ©2015 bulk-online.com)Aerodyne Environmental, a specialist in industrial dust collectors and material handling valves, offers products that can either operate as stand-alone units or as pre-filters for existing dust collection systems. No matter how they are used in a process, their dust collectors can improve efficiencies and removal rates, and help reduce costs and maintenance time. Wet scrubbers have proven to benefit immensely when an Aerodyne dust collector is used as a pre-filter.

The Scrubbing Process

Wet scrubbing usually provides high removal efficiencies as the dust particles are captured in the water droplets. When this happens, the particle size increases, thereby making it easier to remove the dust. A smaller dust particle would be surrounded by a larger water droplet. They are then removed from the airstream together.

While wet scrubbing provides higher removal efficiencies, the downside to this process is that the collected water and dust mixture creates slurry. Handling and remediating the slurry is expensive and difficult. The wet scrubber usually recycles the water it is spraying into the airstream from its sump, but as the solids build up in the water, it has to remove it from the system. This is done by continuously adding clean water to the system and draining slurry from an overflow or diverting some from the recycle stream (blowdown). The drained or diverted material needs to be treated once collected. It is either sent to the facility’s waste water treatment plant or down the drain to the municipal waste water treatment plant. Treating the slurry in the waste water treatment plant or having the municipal facility handle it is extremely costly.By using an Aerodyne SplitStream Dust Collector as a pre-filter, most of the dust could be removed before it reaches the wet scrubber. The SplitStream decreases the dust entering the water in the wet scrubber and allows the end user to decrease the slurry sent to the water treatment plant from the scrubber’s blowdown. Using the SplitStream as a pre-filter also allows you to collect the dust before it is wetted by the water. This will allow you to re-use, recycle, or sell the dust. If the dust is waste, the disposal costs are usually much less for dry solids.

The SplitStream Principle

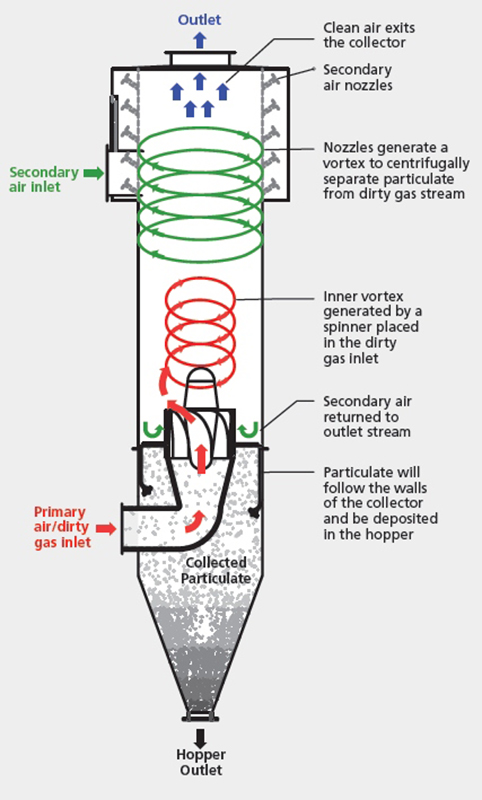

What makes the SplitStream unique from other cyclonic dust collectors is its design and ability to handle tough dusts. With abrasive or sticky dusts, standard dry cyclones will have operational issues. A standard cyclone uses the cyclone walls to knock the dust out of the airstream. Abrasive dust will wear down the walls and cause early failure. Sticky dust will adhere to the walls and slowly build up, changing performance. Aerodyne’s SplitStream cyclone uses a secondary air flow to keep the dust off the walls. This provides long life for abrasive applications and prevents dust from building up with sticky dust. Additionally, Aerodyne’s SplitStream can be configured horizontally or vertically to better fit the application.Placing the SplitStream in front of the wet scrubber and used as a pre-filter will allow you to get the best of both a wet and dry scrubber. The dry cyclone will remove the majority of the dust in the airflow and allow you to save money on dust disposal/re-use. The wet scrubber will provide the high removal efficiency of the smaller particulate and when using the SplitStream as a pre-filter the end user won’t have to be concerned about disposing of the slurry.

| About the Author | |

| Tom HobsonPresident and OwnerAerodyne Environmental, USA |

■