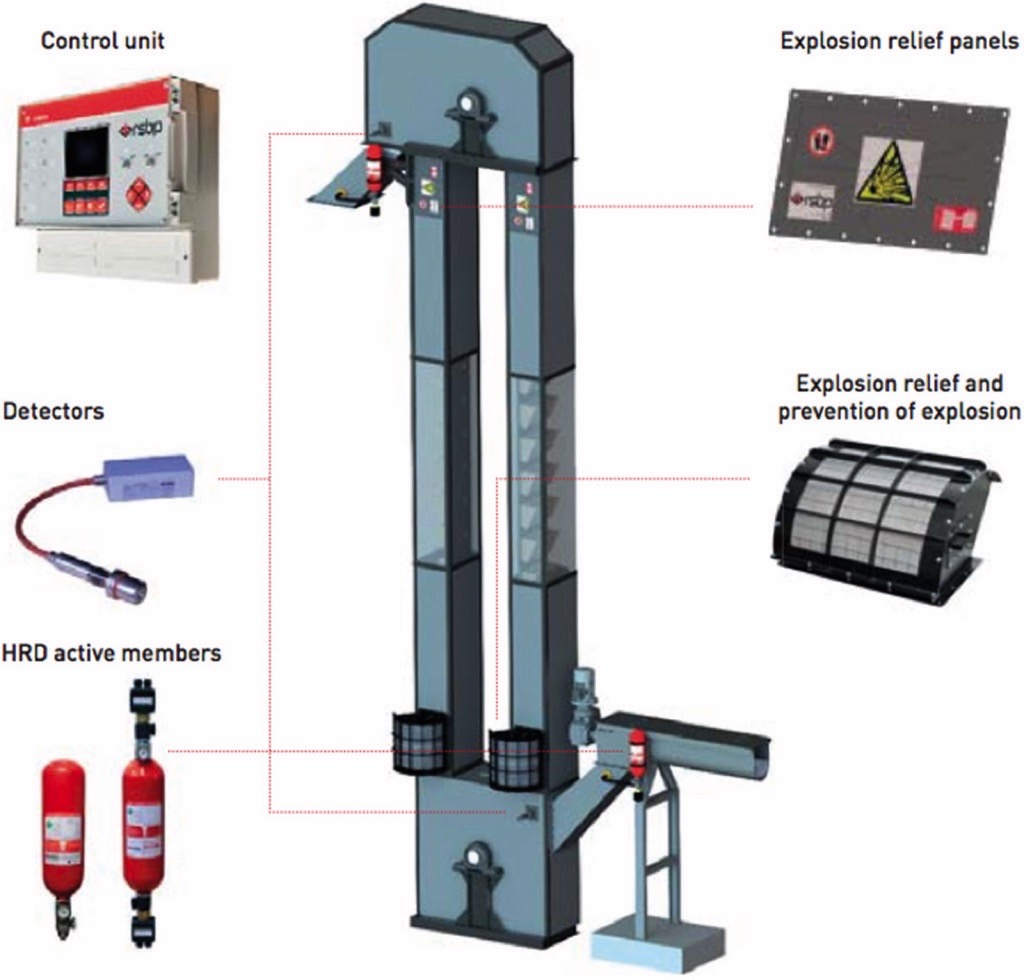

One of the most effective ways to protect vertical conveyors (pieces of technological equipment for the transport of solid bulk materials) is the newly developed Elevex system. By utilising such compact and thoroughly tested protection system, vertical conveyors can be safely protected against explosion effects.There are a lot of examples for the use of such systems, from protection using FVP type explosion panels, through the Flex flameless relief and the HRD Pro explosion suppression system to an HRD barrier or a mechanical closing system.

The character of transported bulk materials can be altogether different. Examples are for instance granulates, grain or spheres containing fine dust that is spread throughout free space and transported by a moving conveyor. An explosive atmosphere occurs inside these conveyors, for example redler, pipe-chain, belt and Z type conveyors or bucket elevators. Due to the material transport principle in a bucket elevator there are inevitable factors, whose consequence may by an explosion. Such explosion risk is significant; therefore it is necessary to protect these vertical conveyors.

One of the most effective anti-explosion systems for vertical conveyors is an explosion suppression system. Specially designed detectors provide timely and accurate detection that monitors a protected object in periods shorter than 1 ms. An output to a control center and then to activators provides an immediate impulse for opening of an HRD bottle valve. Beyond this, thanks to newly developed nozzles and action members, an extinguishing agent is perfectly and evenly spread in the whole protected area. Thanks to this the Elevex system is able to suppress an explosion far under the borderline 0.2 bar.For customers who prefer mechanical protection there are flameless systems with highly effective flameless relief. Due to outstanding relief effectivity and the structure of flame filter the safety zone has a minimum footprint. This provides for safe movement of personnel in the close proximity of the protected plant element.For outside applications, where a safety zone must be determined, we can use specially adapted explosion relief systems of FVP types that provide 100% relief effectivity.The RSBP Company offers two systems for effective explosion isolation in vertical conveyors – a mechanical and a chemical barrier.

■