Dramatic reduction in energy use and environmental impact can be achieved with sandwich belt high angle conveyors that serve as the vital link in any In-Pit Crushing and Conveying system (IPCC). These high angle conveyors are not new at all, but have not found wide use in IPCC systems where they can realize the greatest advantage.Reduced energy consumption and environmental impact with IPCC systems was already realized in the 1970s. With the bulk material haulage limited to conventional open trough conveyors, the most direct path out of the open pit was not possible, requiring low angle spiral ramps and/or deep slots and/or tunnels through the high wall of the open pit. These excavations, to accommodate the low angle limitations, represented undesirable impact on cost and on the environment.Against this backdrop, a major study in 1979 sought to develop high angle conveying systems that could continuously haul the mined bulk material directly out of the pit, along the high wall – the shortest distance between the two end points. Between 1979 and 1982, that study developed sandwich belt high angle conveying systems that utilized all conventional conveyor equipment, including smooth surfaced rubber belts that could be continuously scraped clean. These systems had all of the positive features of conventional conveyors but overcame the angle limitation. By hugging the bulk material between two belts, the material’s internal friction could be developed to facilitate conveying at any high angle up to 90° (vertical).After an intense testing period (about one year) on the first large scale prototype system, commercialization began in 1983 with the installation of a 60° incline system at a western USA coal mine, elevating 2000 t/h of coal to a train load-out system. It did not take a long period of scrutiny and acceptance before this high angle conveyor found use in the most rugged requirements of an IPCC system. This was only the second commercial sale, and after more than 150 commercial installations, it remains arguably the most significant high angle conveying system. In 1984, the Majdanpek copper mine in Serbia, already using pit perimeter crushing and conveying, decided to move their primary crusher deep into the pit and to use a sandwich belt high angle conveying system to elevate the ore continuously, directly out of the pit, along the high wall to the pit perimeter where it then transferred to a conventional conveyor for the remaining haul to the plant.The system had significant features, including 2000 mm wide belts that elevated 250 mm coarse ore, at 4000 t/h, over six 15 m high benches for a total 90 m of net lift. The system was able to reduce the truck haulage fleet by ten 200 t trucks realizing great cost savings, zero emissions to the air, and greatly reduced traffic congestion in the pit. The system operated successfully until 2002 when the mine shut down. Many successful sandwich belt high angle conveyors followed with the current count of commercial installations at more than 150. Despite the great success in the Majdanpek system, its use has not been repeated as part of an IPCC system.The high angle conveyor offers the link to optimization of any IPCC system, yet that industry continues to struggle with the use of conventional conveyors and haul trucks to achieve the high angle function. The results are sluggish low angle conveyor systems of limited flexibility requiring excessive maneuvering time, excessive excavation and fill, re-handling and grading in order to accommodate the low angle limitations. The current alternative to conveyors is the fall back position of using ever larger (+300 t) haul trucks at great operating and environmental costs. Recent studies have represented resurgence in interest in high angle conveying and have demonstrated the technical and economical advantages along with the reduced environmental footprint.Though the primary purpose is to demonstrate suitability for open pit mining applications, this article will first recap the early development of the latest sandwich belt high angle conveyors and their commercialization over the last 30 years. Particular emphasis will be paid to who did what, and when, giving due credit. This will show that since 1979, the constant of the development is the invention and the work of the writer. The article will highlight the features that make Dos Santos sandwich belt high angle conveyors particularly energy efficient and suitable for use in the harsh requirements of the IPCC systems, highlighting the success in Serbia (former Yugoslavia) and in the latest studies. We make a brief comparison with pipe conveyor systems. Finally we ask the question, why is this gift so often treated with such suspicion and then declined?

Introduction

This article deals predominantly with the Dos Santos Sandwich Belt High Angle Conveyors, a technology that is more than 30 years old. To clarify; by Dos Santos Sandwich Belt High Angle Conveyors this article is referring to the work of J. A. Dos Santos since 1979 while in the employ of the various companies:

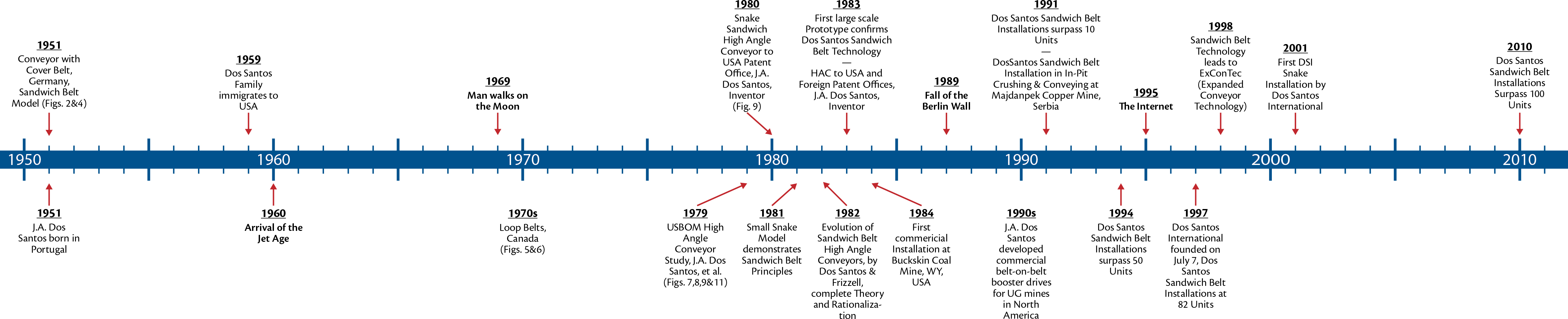

- While at Dravo Corporation, Pittsburgh (PA), USA: Development work of 1979 to 1981, under a US Bureau of Mines study; it was here that this author developed the sandwich belt high angle conveyor technology, rationalized in the conventional conveyor technology. This also produced the landmark publication “Evolution of Sandwich Belt High Angle Conveyors”, a writing that is complete in defining the theory and design rules and in the conceptualization of the designs that went on to commercialization.

- While at Continental Conveyor and Equipment Company, Winfield (AL), USA: The HAC Systems from 1982 to 1997

- Since the founding of Dos Santos International: The DSI Snake Sandwich and GPS (Gently Pressed Sandwich) High Angle Conveyors from 1997 until the present.

The study and research work began in 1979. Commercialization began with the first sale in 1983. The first sale as part of an IPCC (In-Pit Crushing and Conveying) system occurred in 1984, only the second commercial sale. That system began operation in 1991 and operated successfully until the mine shut down in 2002. Arguably the most significant Sandwich Belt high angle conveyor to date, it is the only IPCC application thus far.With the start of this decade, there was great interest in IPCC systems, particularly in Australia. Innovative mining companies are focusing on high angle conveyors as the vital link to any IPCC system. This has led to some significant mine planning studies that are on track for future implementation. The interest has not focused on the traditional IPCC systems, viewing them as old, rigid technology that does not fit their operations; rather they are developing their own IPCC systems with the Sandwich Belt high-angle conveyor as the vital link between their multi-level operations; from the pit to the surface, between benches, to spoil dumps, both on the surface and in back fill of mined out pits. Linked by the most direct path of the high angle conveyor, the system is compact and versatile.It is worth noting that since the 1970s, very little progress has occurred in the second C of the IPCC systems. Aside from high angle conveyors, which have been largely ignored by the prominent IPCC manufacturers, the conveying highlights have included; conventional troughed conveyors that strain, at great risk of slide back, to achieve 18° of incline angle; high powered conveyors with gearless drives; low angle bench conveyors. These are hardly earth shattering innovations.

Sandwich Belt High Angle Conveyor Development

Fig. 3 traces the Sandwich Belt high angle conveyor development time line from the first introduction of “Conveyor with Cover Belt” in 1951, through the USA Bureau of Mines Study in 1979, the first J. A. Dos Santos involvement, through the present. Along the way citing some notable, historical milestones provides some perspective.

Cover Belts of the 1950s

The first introduction of the sandwich belt concept was in 1951, in Germany, in the form of “Conveyor with Cover Belt”. A cover belt was installed at the boom belt of a bucket wheel excavator in order to increase the conveying angle without the occurrence of material slide-back. This was to increase the cutting height of the excavator without increasing the boom length. This first sandwich belt is shown in Fig. 2. Rubber tired wheels pressed onto the cover belt, imparting a hugging pressure onto the material, to develop the material’s internal friction facilitating high angle conveying.A sandwich belt model, shown in Fig. 4, was developed in order to calculate the hugging pressure required to develop the friction that would resist the gravitational slide back forces. Clearly this system was not well executed. The widely spaced pressing tires did not impart a continuous pressure without lapse over the material. The analysis model would be a reasonable basis for calculation if it were accurate. The model depicts a material load that fills to the edges having no allowance for belt misalignment. Sadly, Fig. 4 indicates that the designer believed that such an ambitious material load was possible. Fig. 2 clearly shows that it was not.

Throughout the 1950s, many variations of cover belts were developed and many of these were awarded patents. None of these inventions were a lasting success and by the end of that decade all were abandoned.

Loop Belts of the 1970s

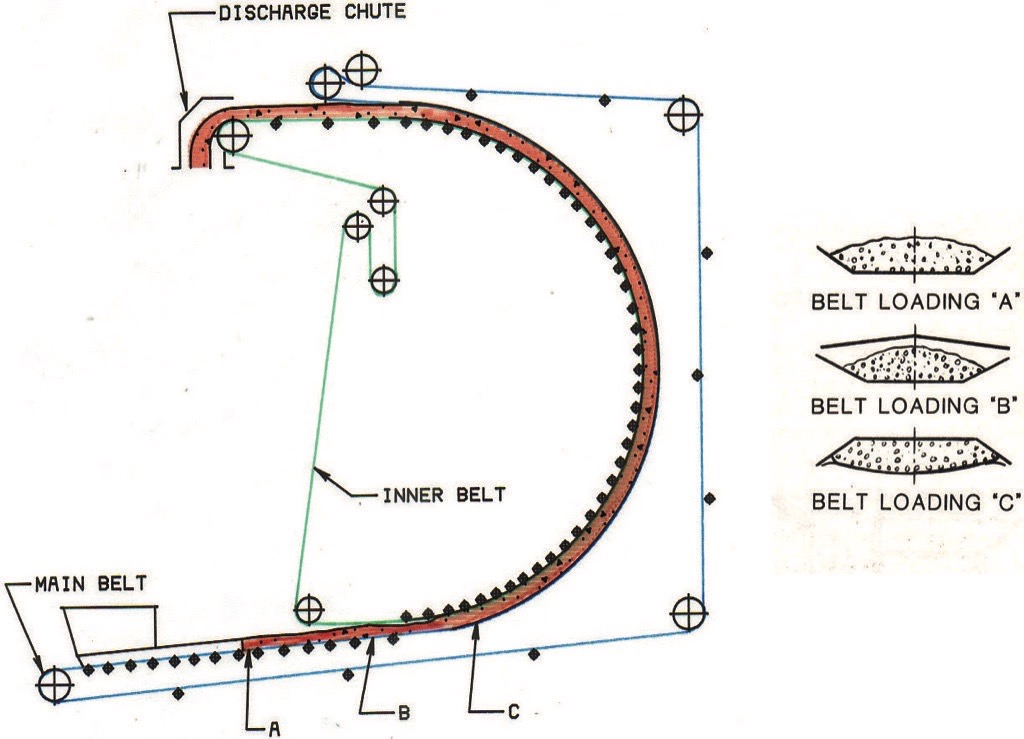

The next development, arguably the most significant, was the Loop Belt of the 1970s. The “Loop Belt” system was developed by Stephens Adamson of Canada as the vital elevating component of a complete conveyor based self unloading ship system. Since the 1970s, these have been used extensively on the Great Lakes of North America. In the 1980s and 1990s, they found world wide use including long haul shipments between North America and Europe and between North and South America.Fig. 5 illustrates the basics of the Loop Belt. Having a C-profile, an inner belt is supported along the carrying-elevating path by closely spaced troughing idlers along the convex curved path until discharging over the inner belt’s head pulley. The outer belt is loaded like any conventional conveyor and carried on troughing idlers up to the start of the sandwich. At the start of the sandwich and through the C-profile, the outer belt radially urges itself and the bulk material against the supported inner belt. In this manner, it imparts a radial hugging pressure onto the bulk material that develops its internal friction – the friction that resists the gravitational slide back forces. The outer belt may tangent off of the carrying path to its head pulley or it may continue over the inner belt’s head pulley in the case of a high angle discharge. Typical Loop Belt arrangements included a long approach of the bottom belt that ran the full length of the ship as the main collector conveyor. The C-profiled elevating portion could follow a tight path through the engine room thus making no imposition on the ship’s cargo carrying capacity.

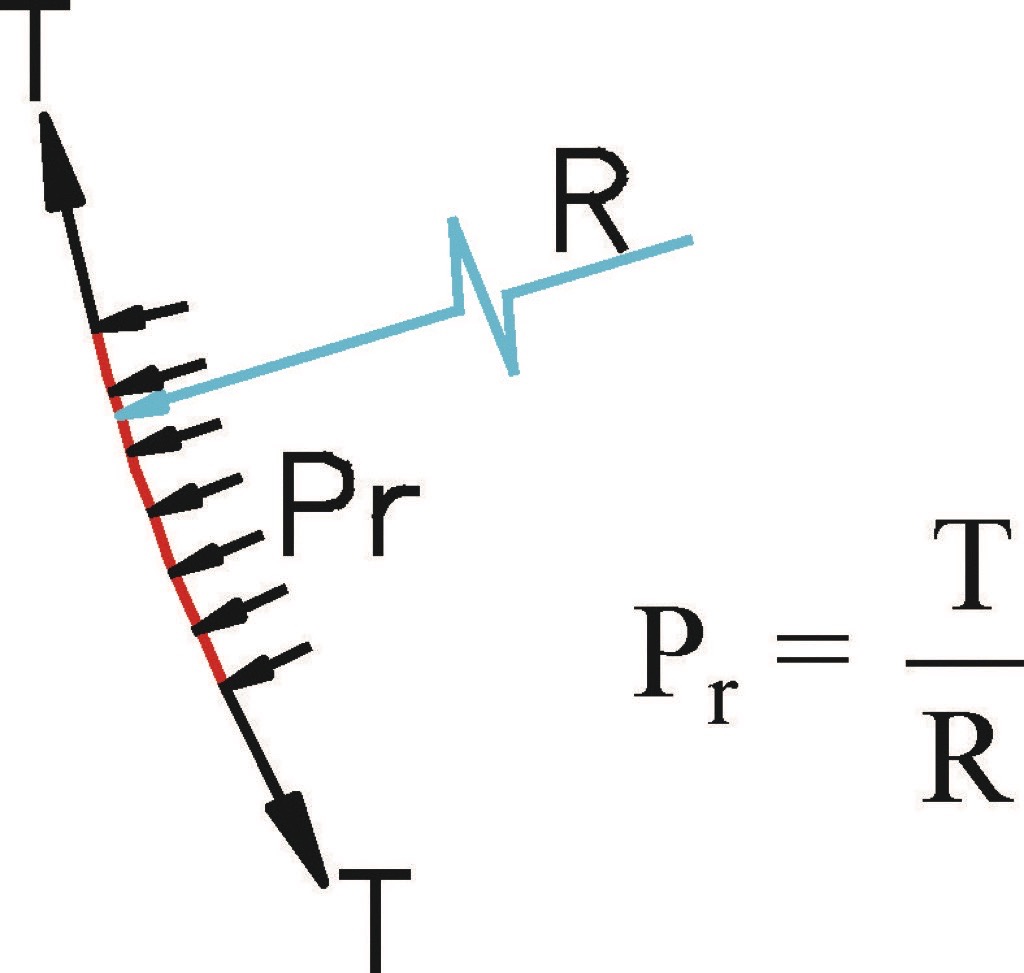

Many Loop Belts were built throughout the 1970s and continue today including several systems by the writer. These systems utilize all conventional conveyor components and equipment including smooth surfaced rubber belts that could be continuously scraped clean. These demonstrated very high tonnage rates exceeding 10 000 t/h utilizing belt widths up to 3048 mm (120 in) running at speeds to 6 m/s. The Loop Belt was first to introduce the concept of radial hugging pressure derived from the belt tension and the curved profile. Though it was not published by Stephens Adamson, this is according to the relationship and equation of Fig. 6.

Dos Santos Sandwich Belt of the 1980s

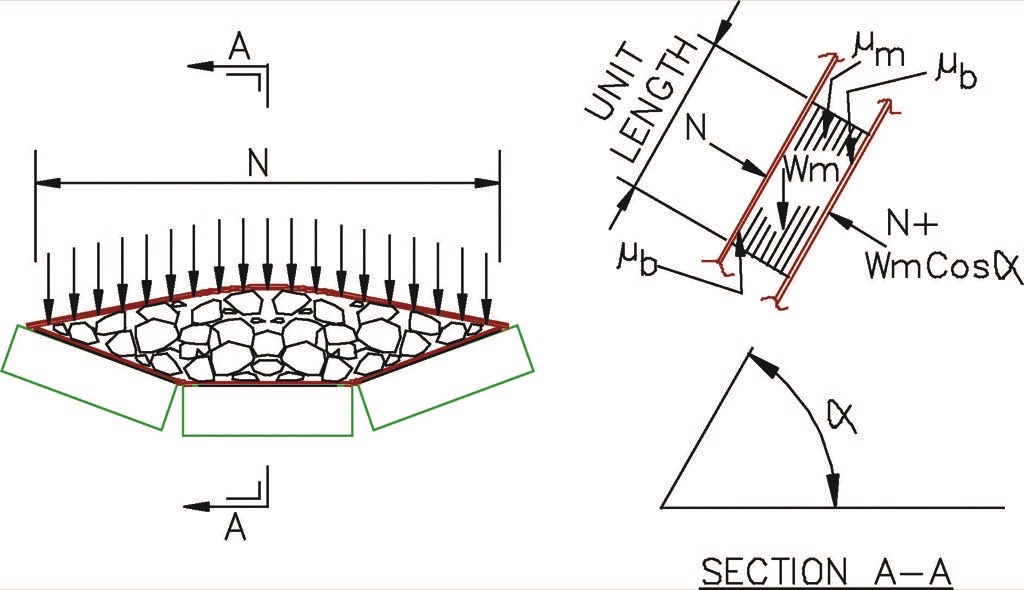

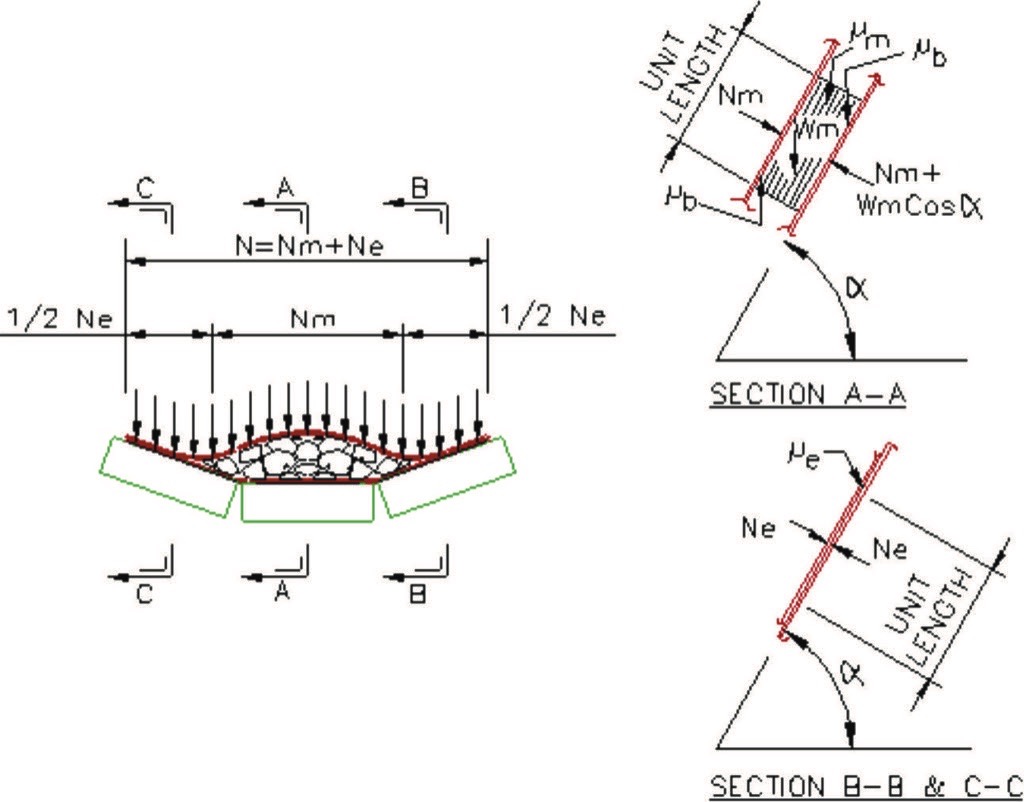

The Loop Belts were the inspiration for the Dos Santos developments of the early 1980s. They featured all of the positive characteristics of conventional troughed belt conveyors. They were well suited for the self unloading ship systems but the C-profile did not provide the most direct high angle path along a general, straight high incline. In open pit mining, this would be the typical path from the pit to the surface along the mine high wall.In 1979, the USA Bureau of Mines awarded to Dravo Corporation a study entitled High Angle Conveyor Study. J. A. Dos Santos was a key member of the study group. The focus was to develop high angle conveying systems for open pit mines; to provide a most direct haulage path from the pit to the surface and to displace mine haul trucks in that duty. The materials to be handled would be coarse, primary crushed ores and waste rock. Haulage rates would be high at thousands of tons per hour.That study considered the state of the art in high angle conveying including bucket elevators, pocket belts, fin belts, sandwich belts and other specialty systems. Though the least understood from a theoretical and design standpoint, for the reasons previously mentioned, the sandwich belts, particularly in the form of the Loop Belt, appeared to offer the best characteristics for the requirements if the profile limitations could be overcome. It was during this study that the writer began the in-depth investigation that resulted in formulation of the theory and standards of sandwich belt high angle conveying, rationalized in the conventional conveyor technology. The guiding principle of the development became the prophecy: “A Sandwich Belt High Angle Conveyor, rationalized in the Conventional Conveyor Technology, will have the operating characteristics of a conventional conveyor – high reliability and availability, low operating and maintenance costs”.The complete rationalization is beyond the scope of this writing and can be found in [2]. A very important element of the rationalization is worth illustrating here. It was necessary to develop a more realistic sandwich belt model to replace the 1950s model of Fig. 4. Such a model is depicted in Fig. 7. It accurately depicts the reasonable cross-sectional filling with enough material free edge distance to allow for the normal misalignment of the belts while running. This means that, compared to the open troughed conveyor, for the same material, rate and speed a sandwich belt conveyor requires wider belts. This does not limit the possible conveying rate as very wide belts and components are available.

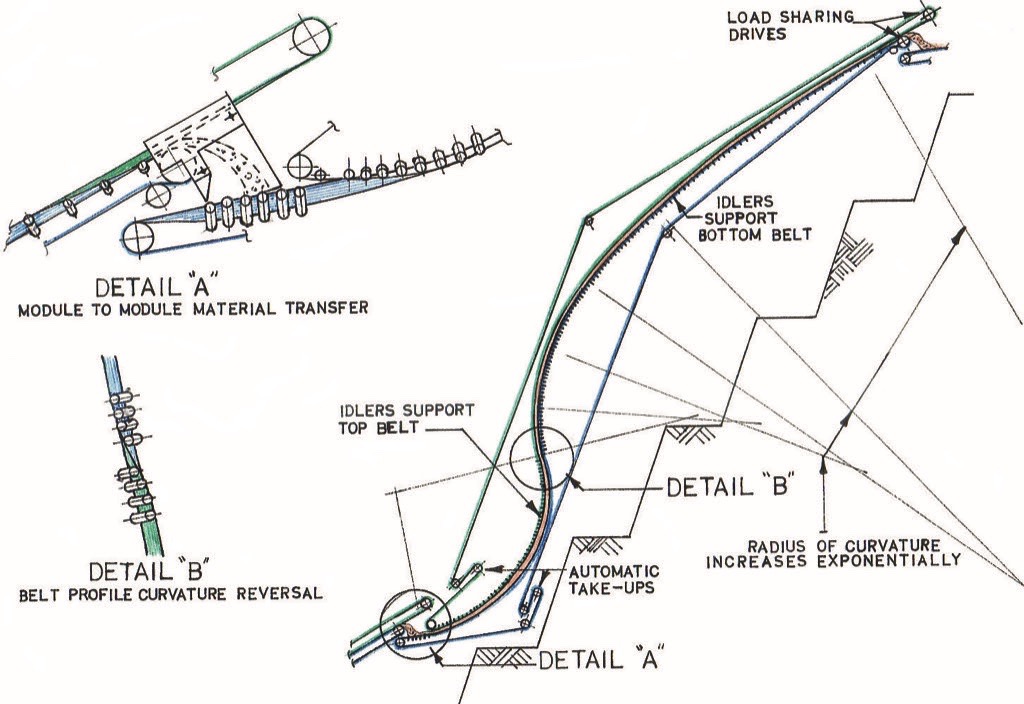

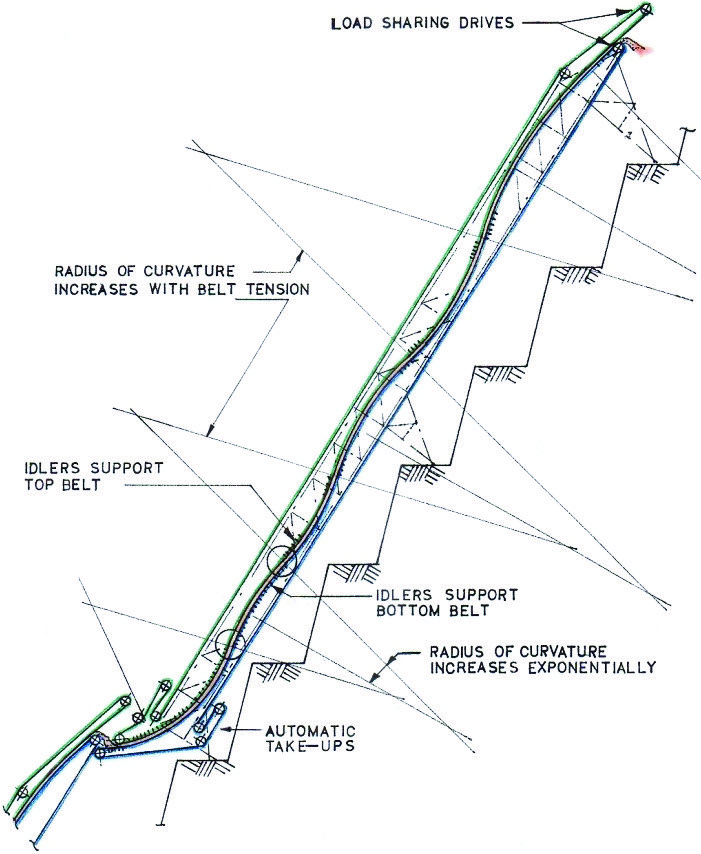

The Dos Santos sandwich belt development began timidly, extrapolating the Loop Belt into a double-loop S-shape. Fig. 8 shows the concept. By introducing a point of curvature reversal along the profile, above that point the approaching outer belt can become the idler supported inner belt while the approaching inner belt can become the outer belt, imparting the radial hugging load that develops the bulk material’s internal friction, to facilitate high angle conveying.

Extrapolating the Loop Belt principle further, introducing a multitude of curvature reversals along the profile produced the Snake Sandwich High Angle Conveyor, illustrated in Fig. 9 as it was first disclosed and submitted to the USA Patent Office in 1980. Fig. 10 shows the realization of the Snake Conveyor, years later, by Dos Santos International.

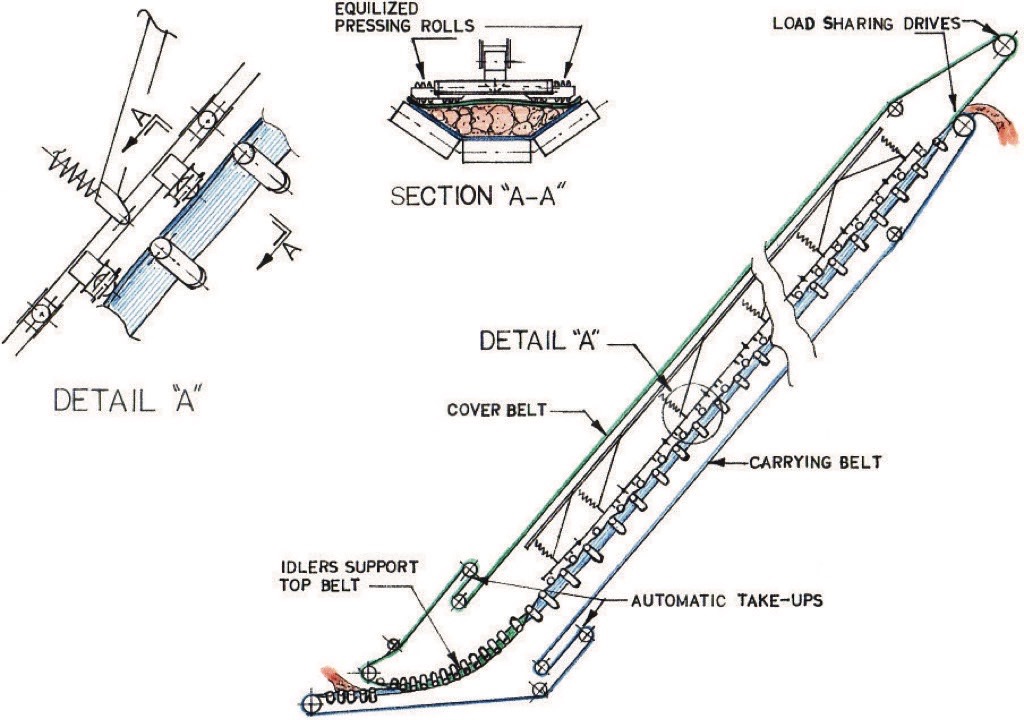

The USA Bureau of Mines (BOM) Study determined that the Snake Sandwich High Angle conveyor was the best solution for the high tonnage requirements of the open pit mining applications. It thus recommended that the system be developed to commercialization.Other variations of sandwich belt high angle conveyors were developed by the writer during the BOM Study. These too were pursuant to the guiding principle of the development – “The prophecy”.The Mechanically Pressed Sandwich conveyor, depicted in Fig. 11, as first disclosed, utilizes equalized pressing rolls on the top belt to apply a hugging pressure onto the conveyed bulk material. Unlike the naturally conforming radial pressure of the Snake conveyor, the mechanically pressed system requires very close attention to equalization and spacing of the pressing rolls, in order to ensure a uniform pressure onto to the bulk material, without lapse. Fig. 12 shows the realization of the Mechanically Pressed Sandwich conveyor, years later, in the Continental HAC.

From the extensive work of the BOM study, J. A. Dos Santos wrote and published the landmark article “Evolution of Sandwich Belt High Angle Conveyors” [2]. That writing, now 36 years old, articulated the complete theory of sandwich belt high angle conveyors, rationalized in the conventional conveyor technology. It established the standards of design that continue to this date.In 1980, at the end of the High Angle Conveyor Study, the USA Bureau of Mines funding was dramatically cut and the Bureau was reorganized and reduced to collecting data and publishing trends. BOM-funded studies of this type came to an end. It was left to Dravo Corporation to carry on the work to commercialization with its own funds. Subject to the same USA economic conditions, after a modest effort of short duration, Dravo management chose not to pursue the technology any further.Continental Conveyor, on the other hand, had been recently purchased by the BF Goodrich Company, a large, well-funded USA company with a mission to become a major player in the mining industry. They determined that a successful high angle conveyor development would give them an advantage. The writer was approached by Continental Conveyor and offered “a chance to put my foot in my mouth”. He accepted the offer and joined Continental Conveyor in May of 1982.With the most important research and development work already done, the Continental Conveyor management was anxious to build a full scale prototype of the Snake Sandwich high angle conveyor and, after a satisfactory testing period, move forward to the commercialization phase. There was an obstacle to this. The Snake Sandwich conveyor, the preferred system, was patent pending at the USA patent office. Though J. A. Dos Santos was the inventor, by the standard USA employment agreement, Dravo Corporation owned the rights to the pending patent. After further consideration and the realization that the obstacle could not be removed, Continental decided to pass up the preferred system. Development of the Mechanically Pressed Sandwich conveyor proceeded instead.The decision to proceed was made in August of 1982. By July of 1983, the large scale prototype and demonstration system was ready to begin operation. Success was immediate. On day one, the system ran with Alabama Coal at 30°. The following day the high angle conveyor was first raised to 45° incline and later to a 60° incline. The coal was conveyed successfully in all cases.In 1983, the HAC patent application, with J. A. Dos Santos as the inventor, was submitted to the USA patent office and to selected foreign patent offices. The patent was awarded in all cases.From there, a year-long testing program revealed the characteristics and limits of the system. The results exceeded our expectations. We did not originally envision running this system above 60°. Extrapolating the test results clearly showed the system would be successful all the way to 90°. Indeed, some years later, the first commercial installation at 90 degrees incline went into successful operation and many more followed.The first commercial sale came in 1983 after that client observed their material, coal, running in the prototype system at up to 2000 t/h. Delivered to Triton Coal Company’s Buckskin Mine, Gillette, Wyoming, USA, the HAC began operation in 1984 delivering coal to train loading silos.The second commercial sale was a significant leap and the first true IPCC application. The 2000 mm belt width system was designed to elevate 250 mm minus primary crushed ore at 4000 t/h from within the pit to the surface. At 93.5 m of lift, the conveyor drives were 3 × 450 = 1350 kW. The system operated successfully, at Maj-danpek mine, from 1991 until the mine shut down in 2002. Ref. [3] describes the project at the time of installation while Ref. [4] documents the performance after five years of operation.Many HACs were designed and supplied by the writer. By 1997, at the time of my departure from Continental Conveyor, the count of HAC units reached 82.At the 1997 founding of Dos Santos International, the writer returned to the preferred system at last, commercializing the Snake Sandwich conveyor. DSI Snakes are now in wide use throughout the world. Fig. 1 shows a particularly interesting DSI Snake at the Port of Adelaide in Australia, a high angle mobile ship loader. Fig. 13 shows the highest volumetric rate Dos Santos Sandwich Belt high angle conveyor to date. Utilizing the widest belts to date, 2438 mm (96 in) running at 4.32 m/s, the system is designed to deliver 4536 m3/h (3629 t/h) of coal along a 50° incline from a Continuous Barge Unloader (CBU) up to the yard belts that deliver the coal to storage. This system, to operate over the Mississippi River in the USA, dramatically reduces the physical and environmental footprint when compared to the traditional switch-back conveyor arrangement that was first considered.

By 2002, the Continental HAC patents expired and DSI began offering their improved mechanically pressed sandwich belt high angle conveyor system dubbed the DSI GPS (Gently Pressed Sandwich).Despite the undeniable success, Dos Santos Sandwich Belt high angle conveyors did not find additional applications in IPCC (In-Pit Crushing and Conveying) systems.

Sandwich Belt Conveyor – the Vital Link for IPCC Systems

Suitability for IPCC systems has been demonstrated at all Dos Santos Sandwich Belt high angle conveyors with a number of units handling very large ore and rock at very high rates. We will approach the suitability issue methodically and then demonstrate the suitability of actual installations.The most common concerns regarding sandwich belt high angle conveyor suitability for IPCC applications:

- Can they handle very high tonnage rates?

- Are they suitable for continuous operation 24/7?

- Can they handle large, heavy, primary crushed ore and waste rock?

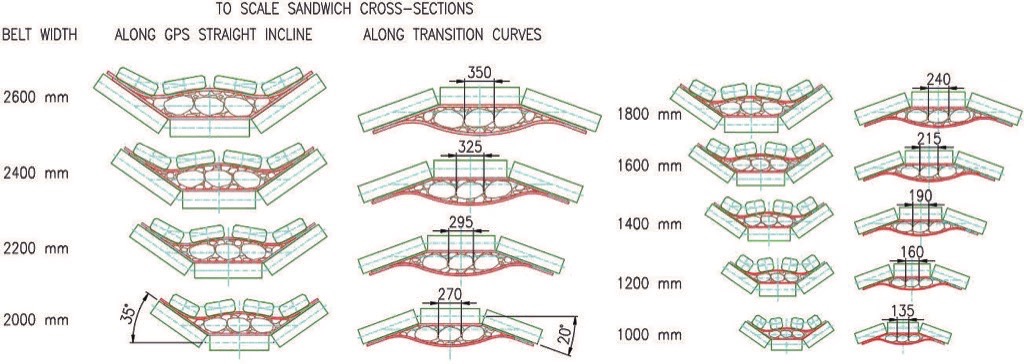

The various installations answer these concerns.Of these, the most important concern is third on the list. The answer is: “large belts can handle large lumps, small belts can handle small lumps”. Fig. 14 shows a to-scale comparison of sandwich belt cross-sections for widely varying belt widths. Clearly, “large” lump size is relative. 350 mm lumps are too large to handle at a sandwich belt of 1000 mm width, but not at a sandwich belt of 2600 mm width. Indeed, to have compatibility of belt width and material size we limit the material size with regard to the trough depth. For predominantly lumpy material, we limit the lump size to the depth of the trough. For occasionally lumpy material (less than 10% large lumps), we increase the size criteria to 125% of the trough depth. This is to limit the separation of the belts, preserving a good covering over the bulk material and positive belt to belt contact at the edges of the sandwich.

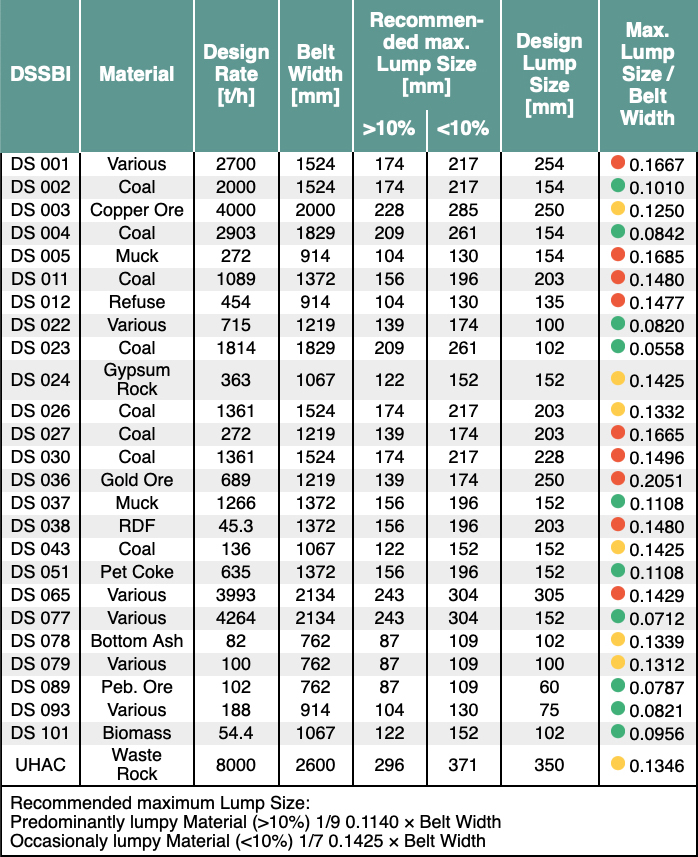

Table 1 lists select sandwich belt high angle conveyor installations, along with the lump size handled, against the Dos Santos lump size criteria. A severity light provides a relative measure of the lump size for the belt width. A green light indicates that the lump size does not exceed the depth of the trough. A yellow light indicates that the lumps handled exceed the trough depth but not by more than 25%. A red light indicates that the lumps handled are in violation of the lump size criteria even for occasionally lumpy material. Nevertheless, the units of Table 1 operated successfully even with the large violating lumps. In such cases, the design, belt speed, components, belt construction and covers were selected to handle the coarse material. Along the convex curves, rubber disc center rolls are typically used to soften the ride when handling large lump materials.

Due to radius of curvature constraints, closely spaced 20° troughing idlers are typical along the sandwich carrying curves. Thus the trough depth that serves as the lump size criteria is that of a 20° trough.It is interesting to compare this with the similar criteria for the conventional conveyors at the same site, subject to the same duties. Generally, for conventional troughed belt conveyors, the maximum lump size criterion is related to the belt width. For predominantly lumpy material, the maximum lump size is BW/5, while for occasionally lumpy material (less than 10% lumps) maximum lump size is BW/3. This compares with the corresponding sandwich belt criteria, of BW/9 and BW/7, listed on Table 1. Recognizing that the sandwich belt high angle conveyor at the same site, subject to the same duty, will always use wider belts than the conventional conveyor, lump size criteria tends to be close to compatible.It is worthwhile to highlight some of the installations. DS 001 is the original large scale prototype and demonstration unit. Here we were able to probe the limits of the system. It was easy to purposely run very large material to see the consequence. It was from this testing, and the later running of the commercial units, that we formed our criteria.Sandwich belt high angle conveyors can and have conveyed very large oversize material from the sandwich entrance to the discharge. At DS 037, a 150 HP TBM cutter motor was unintentionally but successfully conveyed from the loading point to the discharge. There was some very minor damage, but the system continued to operate until a scheduled down time to make the minor repairs. It is not a question of what is the largest material that can be handled. The Dos Santos criteria are to determine the material size that should be handled for reliable trouble free operation with minimal wear and tear.DS 003 is the HAC at Majdanpek Copper Mine in Serbia, the only IPCC application to date. Table 1 and Fig. 14 show that the 250 mm lumps are easily handled at the 2000 mm wide belts.Reference [4] documents the Majdanpek IPCC System performance five years after start up. The system:

- precluded tripling of the truck fleet,

- precluded the need for 4 km of haulage ramps, 3.5 km of which would be of constant ascent, and

- saved USD 12 million per year.

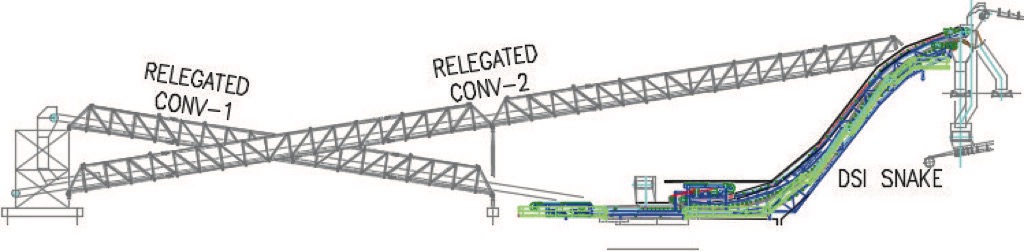

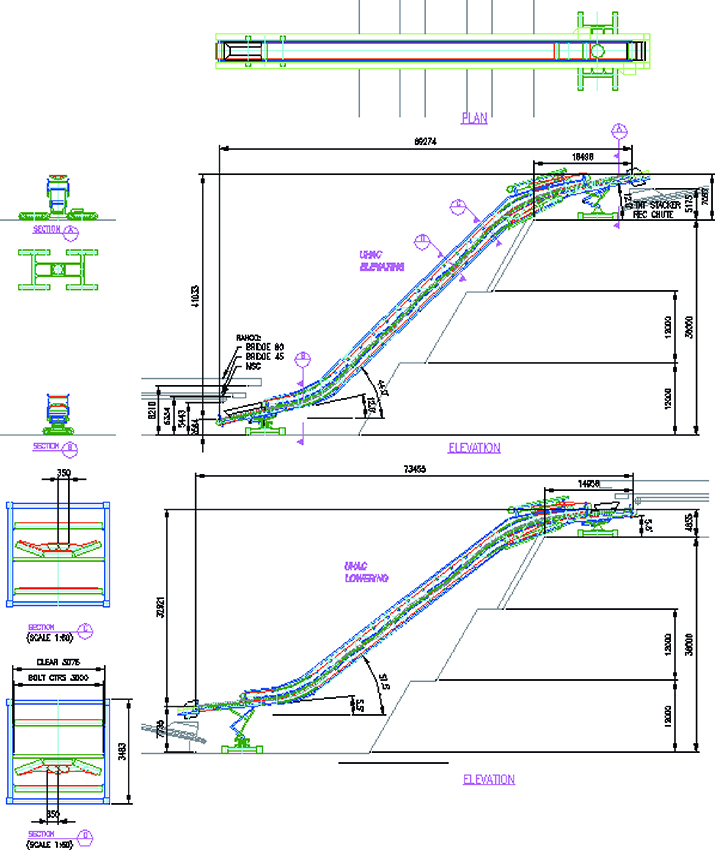

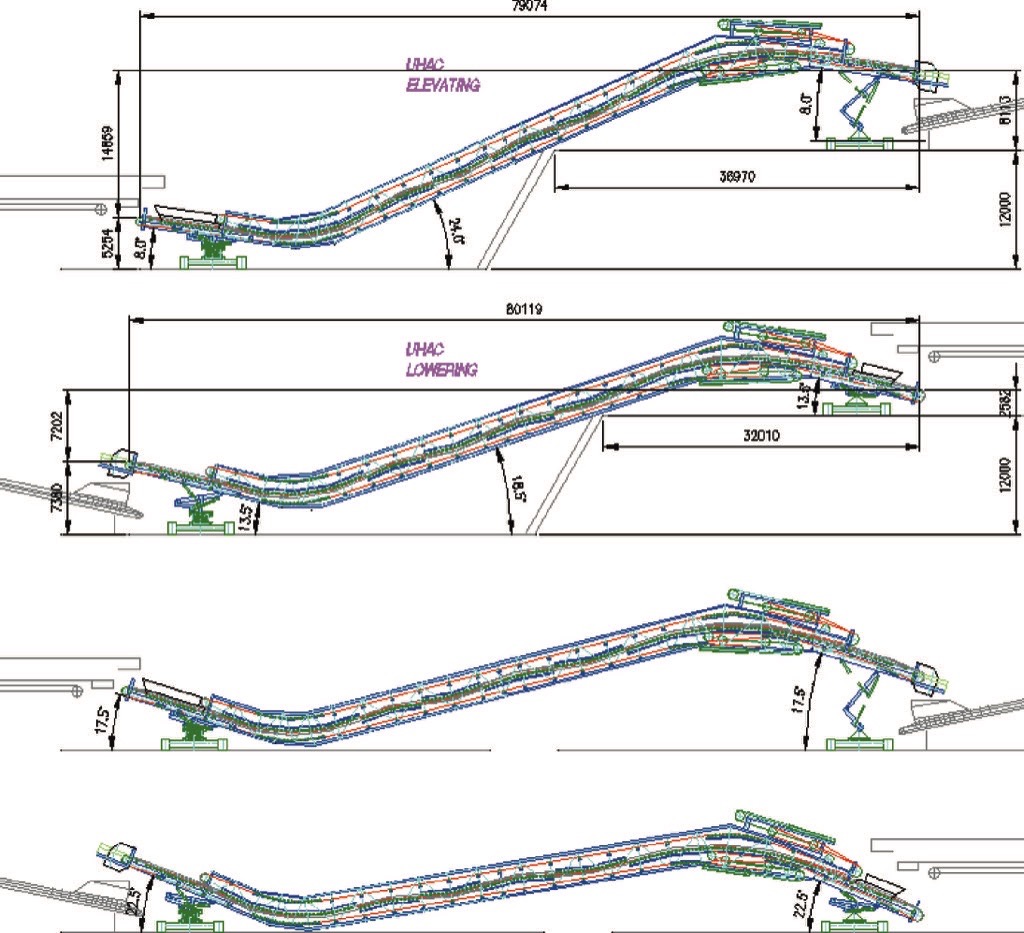

Almost an IPCC application, DS 036 elevates coarse (250 mm minus) gold ore from the primary jaw crusher to the next crushing stage. It is at the pit perimeter, not in the pit. Definitely an overreach on the lump size handled, this HAC suffered some wear and tear consequence. However, it continues to run successfully today.The vital elevating link of a self-unloading ship system, DS 065 handles a variety of materials including 305 mm minus rock. The HAC lifts the material onto a boom conveyor that discharges the bulk cargo to shore. This system is right at the edge of the maximum lump criteria for occasionally lumpy material with less than 10% lumps. Design reflected that fact. The very coarse rock material is one of several commodities transported, and the unloading conveyors don’t operate continuously 24/7, rather there is much non-operating time at sea. This system replaced a massive apron type elevator that suffered very costly wear and tear.On the last line of Table 1, the UHAC is a prospective application for Western Australia. It is designed as the vital link to salvage an existing IPCC System that has proven sluggish due to its dependency on long low angle conventional conveyors that link the IPCC system to the remote spoiling system. Operation of the present system proved impractical largely due to the extensive planning required, much non-productive movement, excavation, re-handling and grading work required to accommodate the present low angle link. Presently the system sits idle awaiting the vital link that will free the rigid interdependency of the in-pit system and the remote spoiling system.The UHAC promises salvation, providing a compact mobile link, capable of elevating or lowering the primary crushed 350 mm minus waste rock at 8000 t/h. Designed with the emphasis on versatility the UHAC can operate in either direction (elevating or lowering the material) and at any level from tramming on grade (Fig. 16) to a 3 × 12 m bench operation (Fig. 15). The UHAC offers the vital versatile link for surface spoiling (elevating) or back filling of the mined out pit (lowering).

The “Chevron Mega-Pipe” Conveyor in Comparison

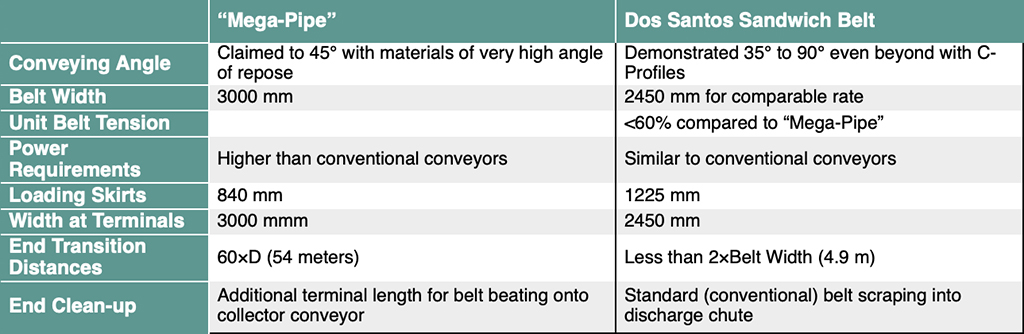

Prompted by the 2016 article “Pipe Conveying – the next Stage” (BSH 2/3 2016), against the above backdrop I now present a comparison of the Dos Santos Sandwich Belt high angle conveyor against the “Chevron Mega-Pipe” conveyor. Table 2 summarizes important points of this comparison. Most importantly the “Chevron Mega-Pipe” is a proposition at this point so that the comparison is that proposition against the long proven characteristics and features of the Dos Santos Sandwich Belt high angle conveyors.

Conveying Angle

Developers of the “Chevron Mega-Pipe” claim high conveying angles from 30° to 45°. Because of the material’s free surface we know that even if all dynamics are suppressed in the running “Mega-Pipe” the best incline angle that can be achieved approaches the material’s angle of repose. CEMA (Conveyor Equipment Manufacturer’s Association) lists angles of repose for most materials from 10° to 39°. Only fibrous intertwining materials such as woodchips, bagasse, etc have angles of repose exceeding 40°. To approach such incline angles the Chevron Mega-Pipe uses high profiled cleats that eliminate the material to belt surface sliding interface and crowd the material between the walls (vertical belt surfaces) of the pipe belt. This is a high price to pay as the former precludes the possibility of scraping the pipe belt clean while the latter is largely the reason why pipe conveyors have increased belt travel resistances and require significantly increased power. Dos Santos Sandwich Belt high angle conveyors always apply a continuous hugging pressure onto the material and can convey at any angle up to 90°. Furthermore power requirements are like any single flight conventional elevating conveyor, only modestly higher than the useful work requirement.

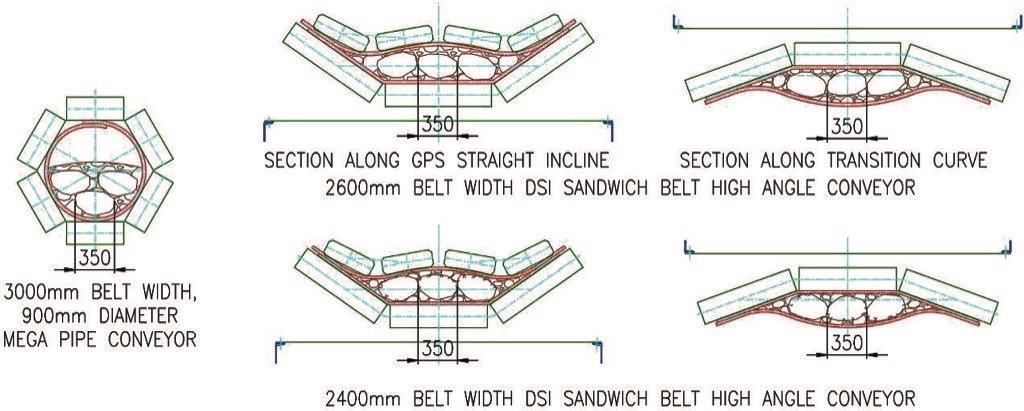

Belt Width, Design Rate and Lump Size

The belt width, capacity and lump size comparison is best illustrated in Fig. 17. This shows, to a common scale, the cross-section of the “Mega-Pipe” carrying strand as well as two carrying cross-sections each of Dos Santos Sandwich Belts of 2600 mm belt width and 2400 mm belt width respectively. The two sandwich belt cross-sections are taken at the transition curve and at the straight GPS incline. The former tends to set the design rate and the recommended material size. For the 3000 mm belt width “Mega-Pipe” I assumed a 30 mm belt thickness, likely an understatement, especially if the chevron cleats are considered.

The design material area at 60% filling (as recommended by CEMA for coarse materials) is 327400 mm2. By comparison, for operation at 45° incline, a Dos Santos Sandwich Belt of 2600 mm belt width exceeds this at 350700 mm2 while a sandwich unit of 2400 mm belt width has a lesser material area of 297500 mm2. Indeed our previously cited system of 2438 mm (96 in) belt width is nearly comparable in material area to the “Mega-Pipe”. Most interesting we have depicted three lumps of 350 mm size at the cross-sections. In the “Mega-Pipe” these must overlap to fit while at the Sandwich belts they line up easily across. Most importantly, they are confined within the rigid “Mega-Pipe” space while there are no rigid spaces within the Dos Santos Belt Sandwich. The sandwich has a floating belt surface that applies the engineered hugging pressure but is free to float on the material even to the point of severe overload. Other aspects worth noting – the “Mega-Pipe” loading skirts must be equally constraining at 840 mm width risking jamming of multiple lumps. By comparison the two sandwich belts depicted will have loading skirt width of BW/2, 1300 mm and 1200 mm respectively.

Terminal Transitions

A most important point of comparison, the end terminals, predicts in the “Mega-Pipe” an imposing system with limited flexibility and conformance to the general pit wall. The “Mega-Pipe” transitions from flat and wide at the end pulleys, to the formed pipe are at least 54 m long according to CEMA. With the additional length required to beat out and dislodge caked material, from the chevron cleats onto a collector belt, the head end terminal length goes up to 70 m. This compares with Sandwich Belt terminal transitions of less than 3 m.

Summary and Conclusions

The two objectives of this writing were to provide the developmental timeline of the modern sandwich belt high angle conveyors and to demonstrate their proven suitability to handle the bulk elevating (or lowering) duties of any IPCC system. The latter was the more important objective and it is supported by the former. So, are sandwich belt high angle conveyors suitable for IPCC applications? This writing has demonstrated a resounding yes when the design is pursuant to the Dos Santos development. The many installations presented demonstrate that:

- they can handle very high conveying rates,

- they are suitable for continuous 24/7 operation,

- high tonnage requirements are handled by wide belts that can easily handle large, primary crushed material, and

- conscientious design, by DSI, will ensure long life with minimal maintenance required.

The system is proven commercially now for more than thirty years with success in a significant IPCC system more than twenty five years ago.End users of IPCC equipment have been disappointed by the large IPCC manufacturers who have failed to embrace the gift of sandwich belt high angle conveying a compact, versatile, vital link to any IPCC system. Some are taking matters into their own hands and with our help they are developing their own IPCC systems with sandwich belt high angle conveyors as the vital link.

References:

- MEVISSEN, E.A., SIMINERIO, A.C. and DOS SANTOS, J.A.: High Angle Conveyor Study by Dravo Corporation for Bureau of Mines. U. S. Department of the Interior under BuMines Contract No. J0295002 (1981), Vol. I, 291 pages, Vol. II, 276 pages.

- DOS SANTOS, J.A. and FRIZZEL, E.M.: Evolution of Sandwich Belt High-Angle Conveyors. CIM Bulletin. Vol. 576, Issue 855, July 1983, pp. 51-66.

- DOS SANTOS, J.A. and STANISIC, Z.: In-Pit Crushing and High Angle Conveying in Yugoslavian Copper Mine. Presented at the Mining Latin America, Int. Mining Convention, Nov. 17-21, 1986, Santiago, Chile, published in proceedings. Published in International Journal of Surface Mining 1, 1987, pp. 97-104.

- STANISIC, Z. and DOS SANTOS, J.A.: In-Pit Crushing and High Angle Conveying at Copper Mine Majdanpek – Performance to Date, Future Expansion. Presented at Fifth International Symposium on Mine Planning and Equipment Selection, São Paulo, Brazil, October 22-25, 1996. Published in proceedings, by A. A. Balkema, Rotterdam, 1996, pp. 487-491. Published in bulk solids handling Vol. 17 (1997) No. 1, pp. 83-87.

- DOS SANTOS, J.A.: Sandwich Belt High Angle Conveyors according to The Expanded Conveyor Technology. Presented at the SME-AIME Annual Meeting, Denver, CO, 1999, published in proceedings. Published in bulk solids handling Vol. 20 (2000) No. 1, pp. 27-37.

- DOS SANTOS, J.A.: Dos Santos International –Company Profile. bulk solids handling, Vol. 21 (2001) No. 2, pp. 216-219.

- DOS SANTOS, J.A.: High Angle Conveying the Vital (missing) Link to IPCC Systems. Australian Bulk Handling Review – ABHR, July/August 2013, pp. 44-53.

- MINKIN, A., BORSTING, P., and BECKER, N.: Pipe Conveying the next Stage. bulk solids handling Vol. 36 (2016) No. 2/3, pp. 16-23.

| A Note From the Author |

|---|

|

Some Information about this ArticleBased on a presentation, by the writer, at the (In-Pit Crushing and Conveying) IPCC 2012 Conference, held in Bali, Indonesia, 25th and 26th of October 2012, an earlier version of this article was published in the Australian Bulk Handling Review – ABHR July/August 2013 issue. That publication made the case for high angle conveying against the low angle limitations of conventional open troughed conveyors. No comparisons were made against other conveying systems – particularly pipe conveyor systems which we have never considered suitable for high angle conveying. Prompted by the 2016 article “Pipe Conveying the next Stage” (BSH 2/3 2016) and its disparagement of the Dos Santos sandwich belt high angle conveyors, we do present here a comparison of the sandwich belt high angle conveyor with the Pipe Belt. |

■