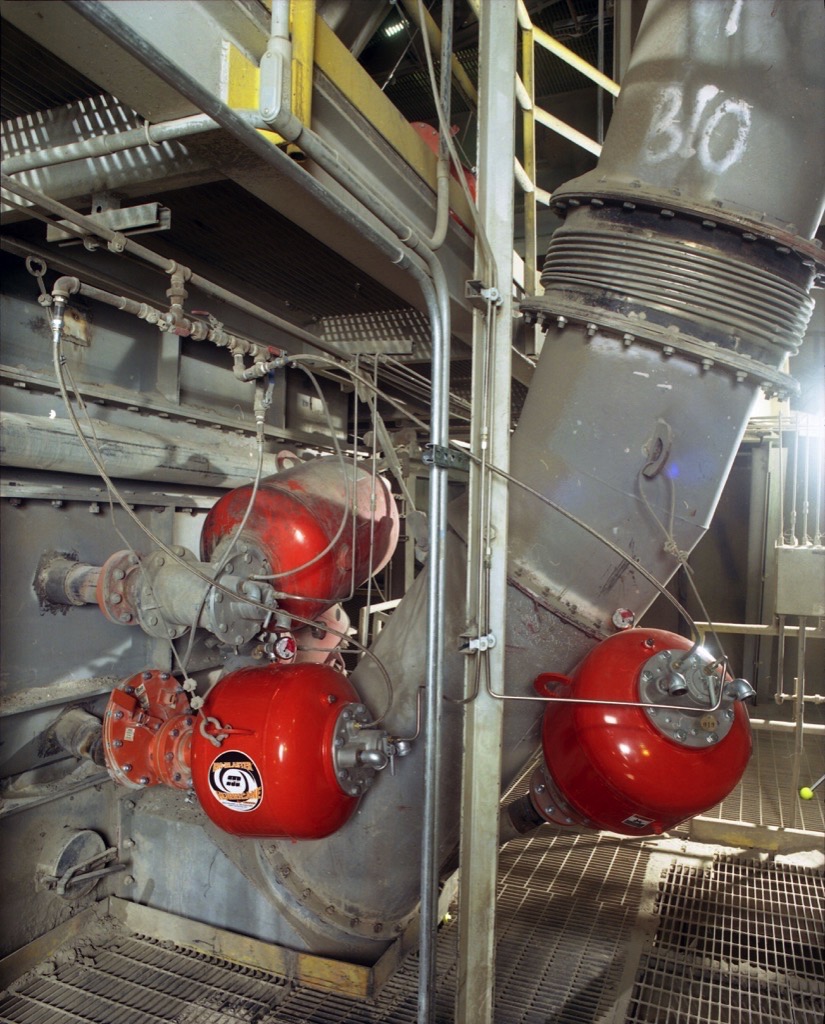

(From the archive of ”bulk solids handling", article published in Vol. 35 (2015) No. 2 , ©2015 bulk-online.com)Air cannon technology has proven itself as an effective flow aid over four decades of use in cement manufacturing, coal processing, ash handling, rock crushing and other applications. Also known as air blasters, air cannons help improve throughput and reduce build-up with an engineered air discharge, dislodging accumulation and preventing build-up that impacts process efficiency and raises maintenance expenses. Common uses include emptying bulk storage vessels, purging boiler ash, improving crusher throughput and cleaning high-temperature gas ducts.

There have been many advancements to the air cannon since it became a commercially viable technology in the early 1970s, which have improved cleaning performance, energy efficiency and safety. Among the changes is a high-speed valve design that can be mounted on a smaller air reservoir, yet deliver higher discharge forces than less efficient valves on larger tanks. The new generation of valves produces about twice the blast force output of the designs introduced just a decade ago, saving energy by using about half the compressed air volume.Another energy-saving development is the piston return reservoir. During the air cannon’s firing sequence, the return reservoir’s canister pressure approaches that of the tank, but the fast-acting valve closes with about 50% of the tank’s original pressure remaining. The peak force output remains the same, but air consumption is dramatically reduced, easing the demand on plant air supply and saving money.

Air cannons have also become safer in recent years, with new positive-firing valves that respond to an air pressure surge delivered by a solenoid valve. This improves air cannon safety, as discharge requires a positive signal. Unlike negative pressure-firing designs, a cannon equipped with this type of valve will not discharge accidentally in response to a drop in pressure, so an air supply failure or broken line cannot trigger it.In fact, researchers now believe that recent innovations have pushed the performance of air cannon technology near its physical limits, with valve cycles measured in milliseconds and efficiency at an all-time high. For this reason, more R&D effort is now being directed at the nozzles themselves, which create the air pathway that actually contacts the accumulated material. Manufacturers are finding evidence to support the hypothesis that new nozzle designs still hold significant potential for improving overall effectiveness, particularly in applications with difficult materials or extreme operating conditions.

Nozzle Development

The cement industry is an excellent proving ground for air cannon technology, as it presents such a demanding operating environment, including extreme temperatures and abrasive materials that affect nozzle wear and service life. It’s also one of the industries in which air cannon technology is most widely used, helping to solve accumulation problems in preheater towers, furnaces, clinker coolers and storage vessels. Yet the air cannon itself is just one component of the solution.A critical but often overlooked aspect of the system is the heat-resistant nozzle designed and manufactured to deliver the optimum force and blast pattern to suit the application. These nozzles are currently available in a variety of shapes, sizes and materials of construction. Over the last two decades, the most commonly used are cast alloy fan shapes and stainless steel pipes. While a pipe nozzle is reasonably light and easy to install, it has a limited area of influence on a flat vertical wall. In contrast, the fan nozzle typically has a wide area of influence and shorter range, but frequently weighs in at 70 pounds or more, making it hard to install and even more difficult to replace. Installing fan nozzles is especially problematic on an existing system, as it requires torch cutting of the vessel wall, drilling through the refractory, then holding the heavy component in proper position while it’s welded in place.As the evolution of cannon and valve technology nears its logical limits, researchers are beginning to focus more on nozzles as a way to improve system performance, better customizing blast patterns and forces to suit the materials and process conditions of individual operations. The nozzle is the component that takes the stored energy in the form of compressed air and directs it to do work, so it has a dramatic effect on the performance of any air cannon. The application dictates the type of performance needed, including the shape of the air blast, length of the plume, etc. In addition to dislodging accumulated material, a goal in every application is to use the stored energy as efficiently as possible.

There has been some advancement in nozzle technology for air cannons over the last few years, such as a 360º retractable design that extends into the material stream only during the firing cycle to protect itself from extreme temperatures and abrasion. This innovative design solves two common industry problems: effectively dislodging accumulations in hard-to-reach areas without shutdown or manual labor, while significantly extending nozzle life. Further, the retractable nozzle can be serviced from outside the vessel, reducing service time and risk of injury.For the most part, however, air nozzles used in today’s high-performance cannons are much like the designs used 20 years ago. Manufacturers offer a range of shapes, sizes and blast patterns to accommodate different materials and process conditions, but nozzle styles and performance have not changed significantly. Even after its long service history as a material flow technology, air cannon users still have a relatively small inventory of nozzle choices for high-temperature applications.

CFD Modeling

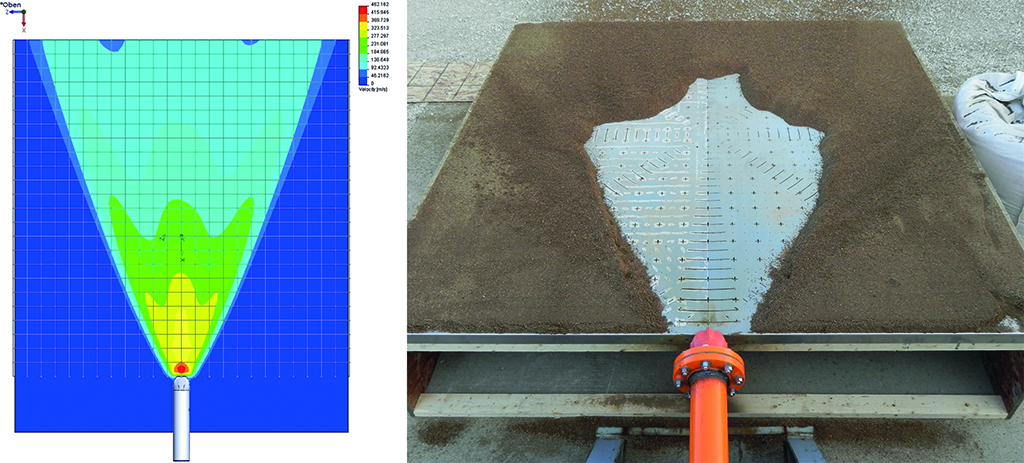

Among the obstacles to new nozzle development has been the lack of precision in existing mathematical models for predicting the performance of new designs, particularly with respect to specific materials or conditions. While existing Computational Fluid Dynamics models could simulate nozzle performance in theoretical terms, the results often varied from the actual performance observed in a customer’s process. In addition, prototype manufacturing has traditionally been time-consuming and expensive, further slowing the R&D process. Selecting the optimum nozzle for specific customer operating conditions often took multiple iterations, making subtle changes to obtain the most effective configuration for that operating environment.With the recent advances in numerical flow simulation software and the advent of rapid prototyping techniques, Martin Engineering researchers felt the time was at hand to create a more accurate standardized model and focus on designing new and innovative nozzles to further enhance air cannon performance. The objectives included development of a predictive theory that better reflects actual performance, accelerating the process from concept to prototype and drastically reducing trial-and-error tactics.If successful, the result would be more effective cleaning performance from air cannon systems, with nozzle designs tailored to individual operating conditions. It was expected that engineers would also develop a deeper understanding of customer processes and foster product development that would be truly process-oriented. The benefits would include current product optimization, cost savings and faster development times, ultimately giving customers a virtually unlimited portfolio of nozzle options.The investigation began with off-the-shelf software and CFD theory. Researchers plugged in the physical parameters of existing Martin Engineering nozzle designs and computed a projected blast pattern for each one. The nozzles were then taken to a test station known as a blast table, where they were mounted on a cannon and aimed at a horizontal surface covered with sand. By firing the cannon across the sand, investigators could obtain an accurate representation of the actual pattern for each nozzle design, which was then compared to the area of influence predicted by the software.Following this series of tests, Martin researchers then revisited the CFD modeling program and made progressive adjustments, eventually resulting in a model that accurately reflected the blast patterns of the company’s existing nozzle shapes and sizes. Armed with this customized model, investigators then turned to the development of new nozzle designs which could be tailored for specific customer operations and process conditions.By progressing beyond a standard range of nozzle configurations from which the best-available solution would be chosen for a given application, the objective was to develop the ability to efficiently design and test nozzles developed specifically to suit individual customer processes, thereby delivering more effective cleaning under virtually any circumstances. Further, the customized CFD model will allow the R&D staff to accurately predict the forces and blast patterns resulting from any new nozzle design, without resorting to the expensive and time-consuming process of prototyping and physically testing every one.

First Development

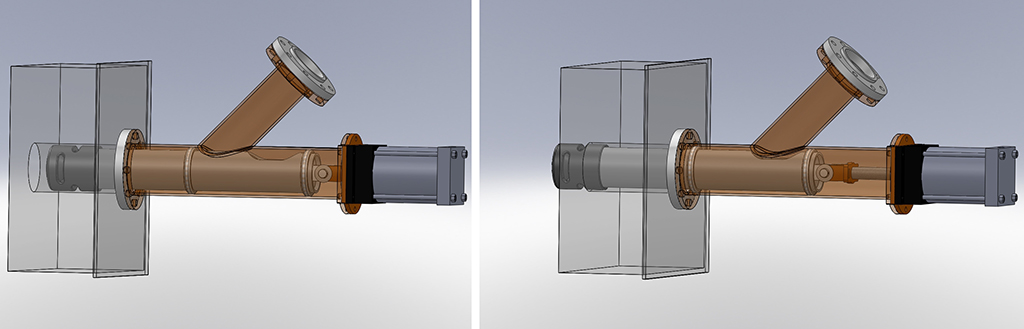

The first nozzle development project using the new CFD modeling technique was initiated to address one of the most common problems shared by high-temperature air cannon users. Replacement of conventional fan-type air cannon nozzles is a difficult and laborious process that affects virtually all systems at some point. The least disruptive time to install a cannon network is during construction of a new system or assembly of a new vessel. When the air cannon system is designed-in from the beginning, technicians can cut the necessary access holes and weld the nozzles in place with relative ease. Refractory can then be fitted around the nozzle opening. But when nozzles fail and require replacement, the process is much more complicated.Replacing a conventional fan nozzle on existing equipment requires the removal of refractory brick from around the nozzle opening, typically with a pneumatic hammer. The process invariably weakens the surrounding refractory and renders it more susceptible to spider-webbing and subsequent cracking. The air cannon is disassembled from the air supply pipe from outside the vessel, and the failed nozzle is cut from the vessel or pipe, usually with a torch. The new nozzle is welded into place, and the damaged refractory is patched as well as possible, followed by the re-installation of the cannon outside the vessel. In addition to the potential refractory damage, the process is labor-intensive, requiring an extended system shutdown, and also introduces the risk of injury from working in a confined space. A key issue is the chance of misplacement, as even a pitch of just 1-2 degrees can significantly affect a cannon’s effectiveness.In contrast, traditional pipe nozzles can typically be changed from outside the vessel, without a need to alter the refractory inside. The cannon is removed from the pipe, and the nozzle can be drawn out through the vessel wall. Unfortunately, pipe nozzles have a smaller area of influence and are generally unable to deliver the same cleaning action as a fan jet nozzle. So Martin Engineering researchers went to work on designing a type of hybrid, one that would deliver cleaning performance equal to standard fan jets, yet be as easy to remove and replace as a pipe nozzle.Using the modified CFD model, the R&D staff conducted virtual testing on several different nozzle configurations, continually refining the size, shape and orifice to investigate the changes in blast pattern. By eliminating the need to prototype and physically observe each design, researchers were able to quickly narrow down the most likely candidates to a very small list. They were able to examine the predicted performance in detail and prototype only those which had shown the most promise in the CFD simulation, greatly increasing the likelihood of success during physical trials.

The patent-pending quick-change nozzle design that evolved from that investigation proved that the R&D team could achieve fan jet performance and combine it with the quick access which in the past had only been available from a pipe nozzle. The CFD model had been demonstrated in a real-world situation, helping the R&D team solve a problem that has confronted air cannon users (especially cement manufacturing operations) for years.The benefits are expected to include significantly reduced damage to refractory brick and drastically shorter nozzle service times. By avoiding the need for confined space entry, the new design has eliminated much of the potential risk involved with the changeout process. It also allows system operators to add air cannons to an existing process during a brief shutdown, without completely cooling down the entire system to allow entry into the interior of a vessel.

In addition to helping researchers solve a specific problem, the process of developing the quick-change nozzle design and field-proving its effectiveness confirmed the utility and accuracy of the customized CFD model. The Martin R&D team now has confidence that they could approach any process experiencing particle accumulation issues and quickly design and manufacture a nozzle to deliver the optimum blast pattern for that specific application. No longer will air cannon users be limited to off-the-shelf choices or lengthy development times to test new designs. The customized software can be used to predict the blast pattern on an unlimited array of variations, and prototyping can be confined to the very limited number of configurations that best suit the individual process at hand.

Conclusions

The benefits of specifying high-efficiency air cannon systems networks for cement manufacturing can include lower energy costs, reduced maintenance, improved safety and greater total output. As the evolution of cannon and valve technology nears its logical limits, researchers have turned to the nozzles themselves as the next opportunity to enhance air cannon performance.By customizing existing computational modeling software, Martin Engineering researchers have developed and confirmed an accurate method of predicting nozzle performance under specific operating conditions, allowing the company to develop nozzle designs for optimum effectiveness, while significantly reducing time-to-market. In fact, Martin Engineering researchers have already used the model to project the performance of hundreds of new nozzle designs.

| About the Authors | |

| Oleg MeisterProduct Development EngineerMartin Engineering, USA | |

| Brad PronschinskeGlobal Product ManagerMartin Engineering, USA |

■