In Germany alone there are more than 260 large flour mills, in Asia the grain market is significantly greater and a very important industry. Whether in Central Europe or in Asia the same problems are met: Well-planned delivery routes and carefully calculated stock levels are vital to achieve maximum cost optimisation during material delivery. These optimisations are often jeopardized by the reality of day-to-day business. Bakeries, the customers of the mills, place their orders too late, forcing the mills to supply material immediately to avoid production stops. What are the reasons for these “fire-fighting” situations and how can they be avoided?

Lack of Storage Management in Bakeries

Even bakeries with multiple storage silos often do not have an automated level monitoring system to control their inventory levels. Therefore their stocks have to be checked manually on a regular basis and an order has to be triggered to the flour supplier on time. Due to unforeseen fluctuations in demand or simply by not having verified the stock levels sudden emergencies arise that lead to unplanned extra tours for the mill.

Installing sensors for level monitoring in the silos of the bakeries would bring a partial improvement. Unfortunately, the willingness to invest is often lacking because “it’s working as it is” and it doesn’t matter that it is a very costly and inefficient way to do it. An ideal solution would be that the mills take responsibility of the level monitoring centrally for their customers and offer this as a special service thus optimising their own material and delivery disposition and at the same time reducing the administrative effort involved. Of course the cost question arises immediately - who is going to pay?

In fact, closer analysis shows that the mill’s investment would amortize itself in a relatively short time due to cost savings from the optimized supply chain process.

Centralized Level Measurement at Mills

Based on UWTs long-term experience the company developed a remote controlled level-measurement system for flour mills: On each silo of the bakery the maintenance-free plumb bob system Nivobob 4000 is fitted for level monitoring. For easy mounting, just a standard 1.5 in threaded socket in the silo roof is necessary.

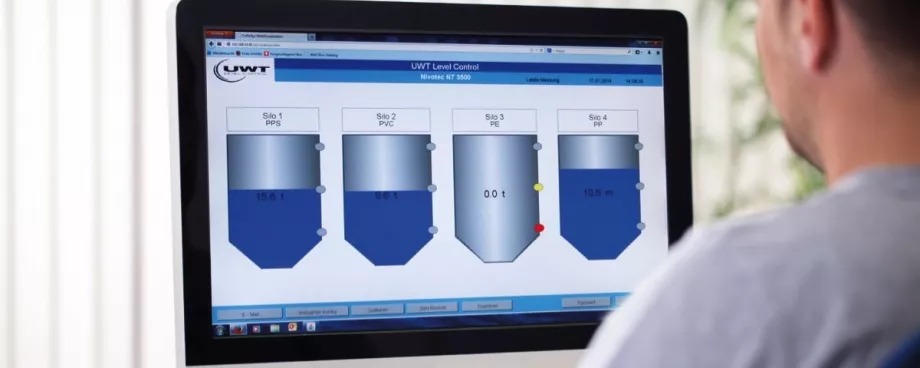

At the bakeries the level signals are bundled by UWTs Nivotec software combined with a Wago Webcontroller. The information received is passed to the web via Ethernet connection and a routed IP address. The mill can securely access this information (password-protected) via any Web- browser at any time of the day. It is possible to include further customers in the visualization system without additional hardware or costs for the mill.

If the priority is to keep installation at the bakeries to a minimum a GSM modem can be used to remotely access the data. In this case only a sim-card is needed in the Wago to pass the modem which collects all level signals and sends them in an encrypted log via mobile phone over the Web to the appropriate controller in the mill. As only small amounts of data are being sent a low priced sim contract is sufficient for this purpose.

The current silo levels can be displayed at the mill control centre using the Nivotec visualization software. The dispatcher can check the real-time status of the silos because the visualization controller is directly integrated into the Ethernet system.

System Advantages and Benefits

The benefit of the whole system is the simplification of the material disposition processes leading to a reduction of costs for all parties involved.

- The installation of the system in the bakery as well as in the mill can usually be carried out by the mills own service engineers.

- Control cabinets only have to be set-up once; later on no additional IT support is necessary.

- All silo levels can be controlled at the same time for stock material safety.

- The system can be dismantled at one customer and installed again at another without extra costs.

The mill is able to hold the correct material in stock according to the customer’s requirements and can optimise the logistical routes and schedules. The availability of the required information can reduce the need for express deliveries or empty runs dramatically. On the customer side, at the bakery, the task of manually checking the material level within the storage silos is eliminated and production bottlenecks due to a lack of material are history.

The material flow now follows a standard process with much greater planning security: Last but not least it naturally leads to a more harmonious working relationship and increased satisfaction on both sides which ultimately mean a stronger partnership between customer and supplier.

■