Issues related to aggregates prices, sales and technical issues of the production are usually among the topics of concern to coarse aggregate quarry managers. Another issue is the mass balance of production because, as part of a normal production process of crushed aggregates, up to 30 percent (rock dependant) of the material acquired from the bedrock is reduced to sizes smaller than 4 mm and thus cannot be used as coarse aggregates.

This co-generated material has long been the most unfavorable fraction in terms of assuring a profitable mass balance, since it can be hard to sell or even to get rid of at any price. As a result, in many places there are huge stockpiles of this “waste” that not only affects the profitability of the aggregate operation, but also causes environmental issues.

In the past few decades, the availability of suitable natural sand for concrete production near the point of consumption has been exhausted around many populated regions in the world. This has led to a search for a replacement material; the aforementioned surplus fines from crushing operations are expected to be the next best alternative – due to both great availability and suitable physical properties.

Natural Sand and surplus Quarry Fines – Differences

Early attempts to use this co-generated material as fine aggregate were mainly unsuccessful. However, today the important differences between natural sand and surplus quarry fines are well known by aggregate producers, and there are examples of the producer successfully overcoming the challenges after working in close cooperation with with the quarrying machinery supplier, e.g. Metso Minerals.

With respect to particle shape, this includes optimizing the crushing process along with vertical shaft impact (VSI) crusher, rock-on-rock shaping at the end. This can result in a particle shape that closely resembles that of natural sand.

The issue of the high fines content can be resolved with either wet or dry processing, i.e. different washing techniques or air classification. Finally, if the sand particles are sieved and classified into reasonably narrow particle sizes of a good shape, they can be successfully used as high-quality manufactured sand already today.

The challenging Task of crushed Sand

Developing new approaches in the field of crushed sand production and then increasing its markets share is not a simple task, one of the reasons being that it involves many parties. This can be described as a sort of “chain”, starting with rock blasting in a hard rock quarry, advancing to rock crushing and screening, then continuing to a ready-mix producer, and finally ending up at the construction site, where the crushed sand concrete is to be evaluated by the end user, i.e. the contractor.

In order to bring all the involved parties together to solve the challenges, COIN, Concrete Innovation Centre (www.coinweb.no), was founded in 2006. Since 2009, Metso Minerals has been an active and key participant in the COIN project “High-quality manufactured sand for concrete”. This focus area has served as a source of funding and a hub for facilitating the crucial networking between professionals from the different industries involved and universities and research institutions. The purpose has been to create a better crushed sand solution for the future.

A new Trend in crushed Sand Production

There are two scenarios for a new approach to crushed sand production. One includes choosing the best available geological resources and then trying to copy “mother nature” by putting extreme effort into shaping of the aggregates and the design of grading curves.

Another approach involves finding ways to make crushed sand perform as well or better than natural sand by utilizing its intrinsic properties. This also includes developing a new concrete mix design philosophy that is adapted to crushed sands with specially engineered properties that are different from those of natural sands. The latter is what has been chosen as the philosophy of the new approach of crushed sand production currently under development within the COIN project.

It is also worth mentioning here that crushed fine aggregates normally outperform natural sand when the most essential hardened concrete properties, such as compressive and tensile strength, are compared. At the same time, the problems of achieving economical mixes with suitable workability (fresh state properties of concrete) are normally reported as the main problem that can render the use of crushed sand non-favorable in many cases.

Performance of crushed Sand – Recent Findings

The current trend in the concrete construction industry is an attempt to increase the market share of self-compacting concrete. This is a special type of very flowable concrete that was developed two decades ago in Japan and is special due to its ability to compact and level itself into a mold without any external vibration.

In the previous work carried out by the author within the COIN project, it was recognized that crushed sand with its naturally high fines content is perfectly suited for this type of concrete. This is because of the high flowability and the fact that self-compacting concrete needs a much higher content of very fine particles (≤ 0.125 mm or 120 mesh) to assure good cohesion between the water and particles in the mix to avoid segregation and also to prevent interlocking of the coarse aggregate grains.

Research carried out elsewhere has also proved that increased fine particle content can in many cases be desirable compared to natural sand concrete. This is because a high fines content in natural sand usually indicates increased silt, clay or shale concentration, which is detrimental to both fresh and hardened concrete properties.

In crushed sand, the presence of these contaminants is rare (at least in Scandinavia) and some level of fines would normally increase the content of filler-modified cement paste, thus helping with lubrication between the coarser aggregates particles (≥ 0.125 mm or 120 mesh). When the optimum level of fines content is exceeded, they start reducing the flowability of the cement paste itself and thus the effect of lubrication with respect to coarse particles can then be overruled.

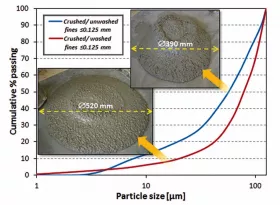

Further trials within the COIN project also proved that the type of the fines mattered as well. This means that not only is the total percentage of fine particles below the sieves 0.250 (60 mesh), 0.125 (120 mesh) or 0.063 (230 mesh) mm important, as normally interpreted in the past, but so are the characteristics they possess; these characteristics can vary widely for different crushed fine aggregates. The most important properties of the fines are believed to be their particle size distribution (specific surface), mineralogical composition, particle shape and surface texture.

For example, if the grading of two crushed fines (≤ 0.125 mm) coming from the same deposit is altered by classification (washing, in this case) and this is the only variable between two concrete mixes (i.e. the total fines content is kept constant), this can have a tremendous effect on the concrete slump-flow value (see Fig. 3).

From a concrete technology point of view, those findings can be explained by the adsorption of the free water on a larger total surface area of a finer grading, thus leaving less water available for the lubrication of the cement paste itself. The recent findings have also indicated that varying the properties (flakiness) of coarser crushed sand fractions (0.125/2 mm and 2/4 mm) has much less relative impact on fresh concrete properties, and that the other fine particle (≤ 0.125 mm) characteristics, such as shape, surface texture and mineralogy, could have a similar effect as grading (specific surface).