1. Review of Common Screen Types

Screening plays a key role in mineral processing in the quarrying industry, ore and coal preparation as well as in the recycling sector. This applies especially in comminution, where only screening enables qualified, accurately sized material to be obtained from crushed material, ready for further processing or sale in this state.

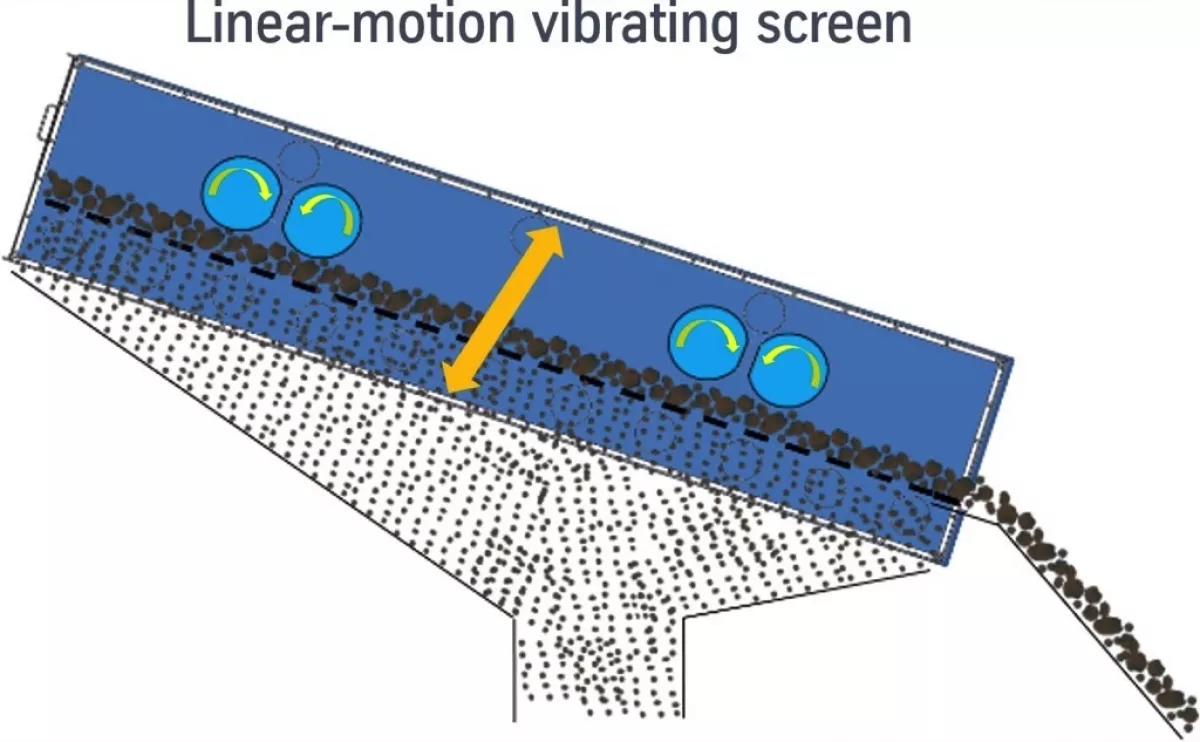

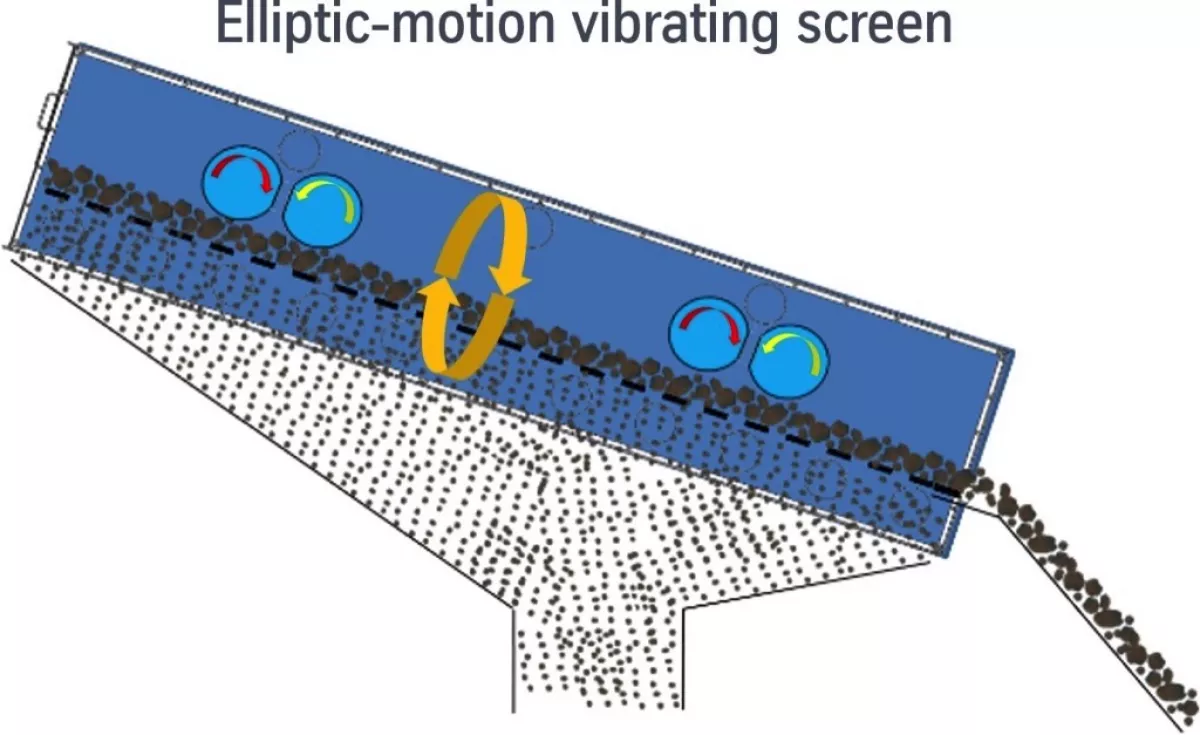

Traditional vibrating screens are either driven by eccentric shafts or vibrated by unbalanced weights and, depending on the mode of vibration, classified into circular-motion vibrating screens, linear-motion vibrating screens and elliptical-motion vibrating screens. Characteristic of all these is that the oscillating driving forces are introduced through the machines’ centre of gravity and the screens are supported at the front and rear in the conveying direction (Table 1). On account of this, the screen trays must be designed to be especially rigid and heavy, in order to permanently withstand the resulting high dynamic loads.

In an assessment of the advantages and disadvantages of the aforementioned screen types, the limited flexibility regarding the operating parameters proves a disadvantage as this makes it impossible to react to changes in the required product quality or to changes in the properties of the feed material. Such modifications can usually only be done mechanically, leading to unscheduled downtime and potentially multiple corrections.

Moreover, synchronization of the drives either fixed on both sides of the screen box (circular-motion vibrating screen) or installed centrally above or below the screening area (linear-motion vibrating screen) is mechanically complex, heavy, and prone to wear as well as requiring lubrication equipment. Especially in case of circular screens, these mechanisms lead to limitations in the design of the screen width, so accordingly only limited throughput rates can be realized.

The considerable space requirement and the high weight of common screen models have repeatedly turned out to be the most prominent drawbacks of common screen types. These characteristics not only affect the screen itself, but lead to high transport and assembly costs as well as having an adverse effect on the structural design environment of the screen and the drive power to be installed. Large and heavy screens require a corresponding substructure and suitable building structures as well as to, for example, longer belt conveyors for the supply of feed material. The higher the weight of the screen trays that have to be driven, the higher, of course, is also the screen’s energy consumption.

On account of the process-related low height of the material bed on the screening area, an unfavourable ratio of screen feed to the vibrating mass results, especially in fine screening. In the screen shown in the Fig. 1, with a width of 4.3 m and a weight of 35 t for screening phosphate, during normal operation, for example, only 300 kg material can be found on the screen deck.

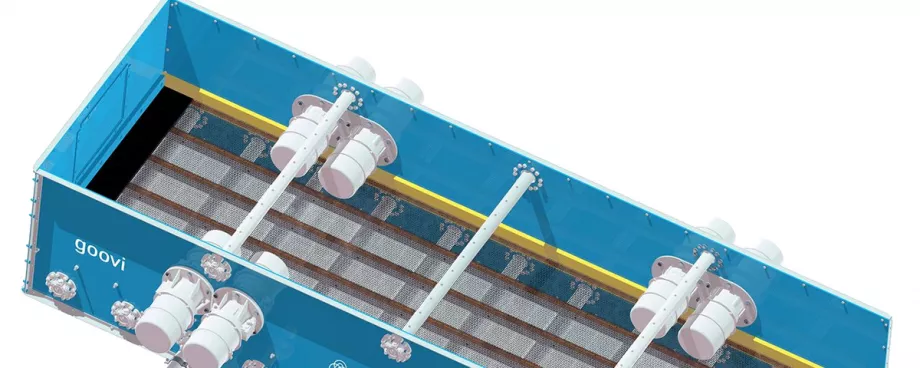

Having considered the observations mentioned above, thyssenkrupp has developed a large number of innovative, intelligent solutions to design screens to be more effective, flexible and economic. The result is the new goovi® multiple vibration screen.

2. Development of the all-new thyssenkrupp goovi®

In the development of the new goovi®, the thyssenkrupp specialists initially concentrated on secondary and tertiary screening as here larger areas of application can be found in the field. These are applications in the gravel and aggregates supply sectors, in mining and recycling, where feed materials with a particle size up to 80 mm are screened with a minimum screen cut of around 2 mm.

With regard to design, the focus of the new development was on the drive concept as this promised the greatest potential for optimization. But trailblazing developments have also been realized for the screen tray, screen support and the control system. Basically, the thyssenkrupp goovi® has been designed for the digital quarry and paves the way for industry 4.0 in processing plants.

2.1 Drive Concept

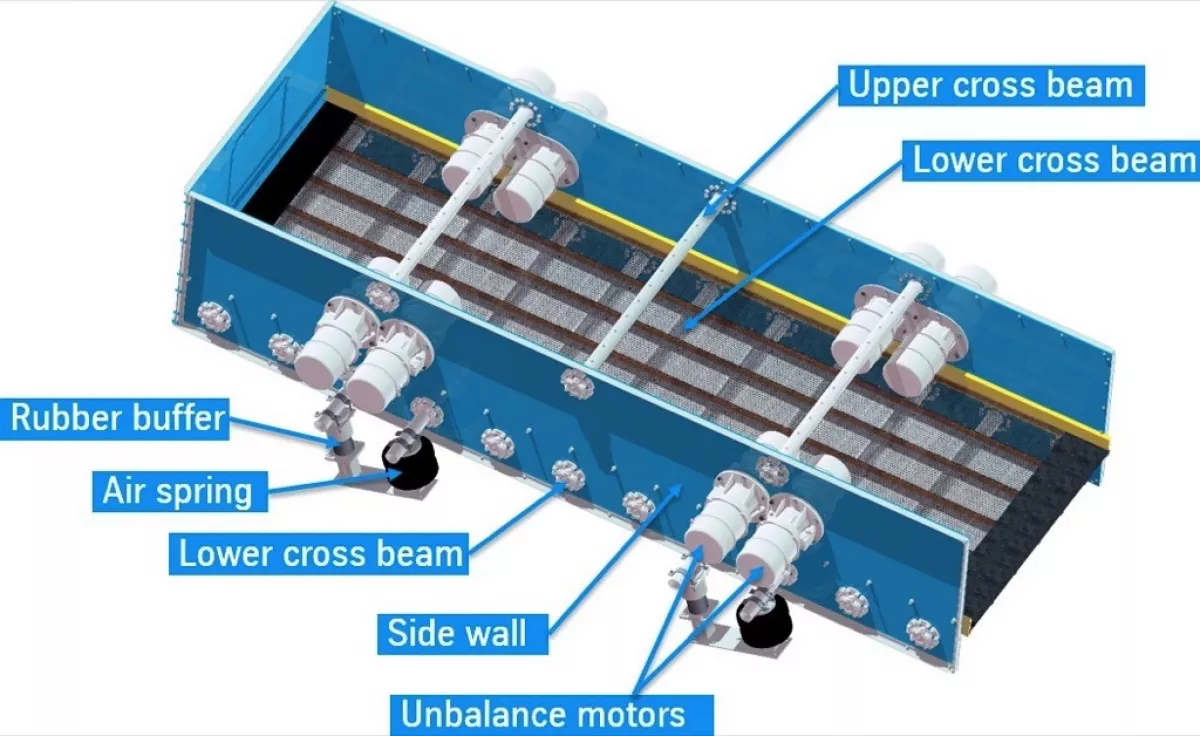

In the specification of the drive concept, the point of force introduction is of particular importance as this influences the static and dynamic sizing of the screen’s sidewalls. Simulations have shown that a screen should ideally be driven at four different points, on both sides in the front and rear areas. For this reason, it was decided to place the drives in the bending nodes of the stress curves in the sidewalls (Fig. 3). In this way, the forces are optimally transmitted into the sidewalls and bending stresses minimized.

At the same time, the drives should be designed to enable higher flexibility and easier adjustment of the operating parameters. For this reason, at every drive point, not only one motor but two or three motors were installed, so that each thyssenkrupp goovi® is driven by 8 to 12 motors. Here, compact lifetime-lubricated standard unbalance motors are used, which are symmetrically flange-mounted to the sidewalls and synchronized by means of a patented PLC system supplied along with the screen.

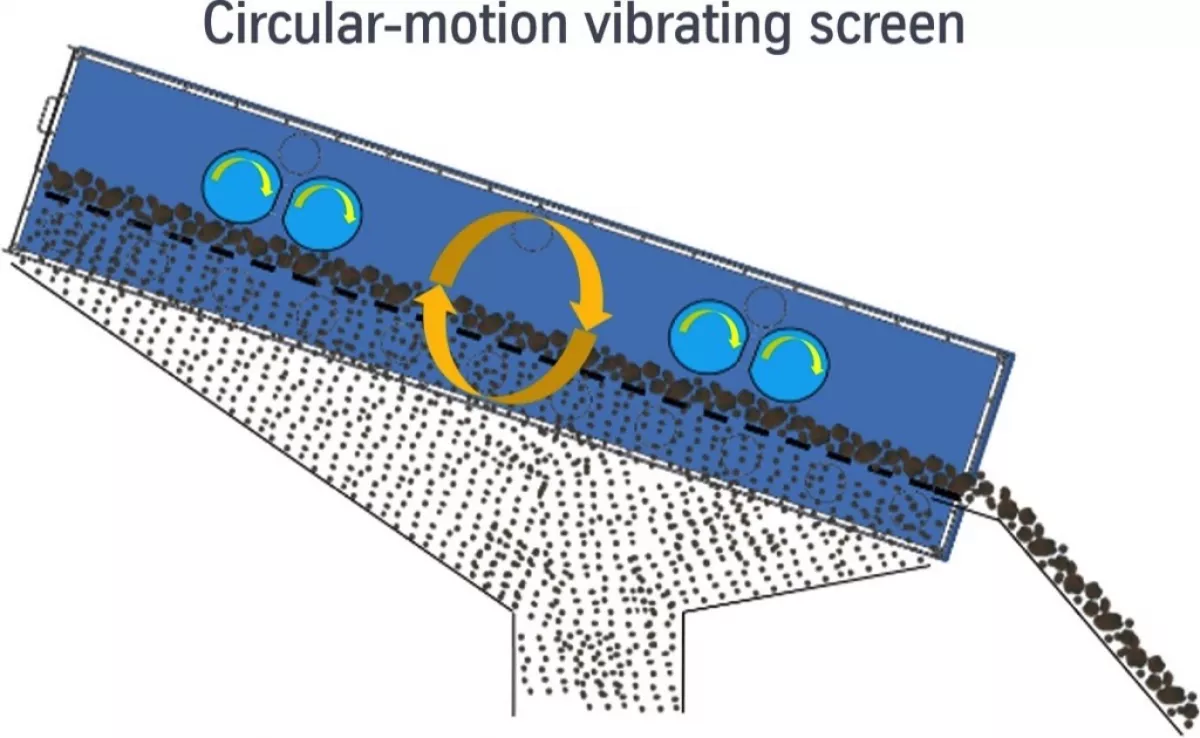

But the PLC system is not only responsible for synchronizing the motors, it can also adjust them relative to each other during operation. When all the motors are turning in one direction, a circular motion is generated (Fig. 4); when the motors in one drive cluster turn in the opposite direction, the screen is vibrated in a linear motion. The PLC system can be used to switch the mode of vibration, without the need for any mechanical intervention. With a change of the eccentric weights of a drive cluster, an elliptical motion of the vibrating screen can be realized, with which the advantages of a circular- and linear-motion screen can be combined. The rotational speed and the angle of throw can be infinitely adjusted so that all important operating parameters can be optimally adapted to production requirements at all times.

|

|

|

Consequently, the goovi® can be adapted to changing material properties that can result from variations in the material deposit or climatic influences, e. g. in form of increased moisture content. Even very difficult-to-screen materials can be optimally classified. Also with one and the same goovi®, but with a change in the operating parameters and, if required, the screening surfaces, different products and product qualities can be obtained, if the market requirements change or, for example, vary seasonally. For this, specific recipes can be added to the control system and called up as needed. For high requirements on the product quality, e. g. in the aggregates industry, control loops can be realized in which screen parameters can be readjusted, if, for instance, there are changes in the product grading curve. Precondition for this is a reliable method for continuous determination and monitoring of the product grading curve.

Particles that clog up the screening surface and reduce screen efficiency can be easily removed thanks to the goovi® self-cleaning function, with which the mode of vibration and direction of transport is changed temporarily. As a result, losses in efficiency and costly cleaning work can be reduced or avoided completely.

The entire drive system works without any mechanical transmission components like shafts or gears as the motors are flange-mounted directly to the screen wall and synchronized electronically. As a result, the maintenance requirement, the weight and the power consumption are reduced considerably. Lubrication is not at all necessary.