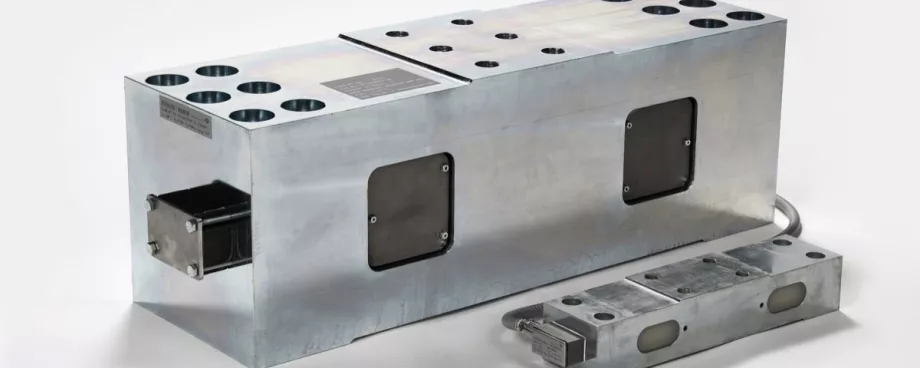

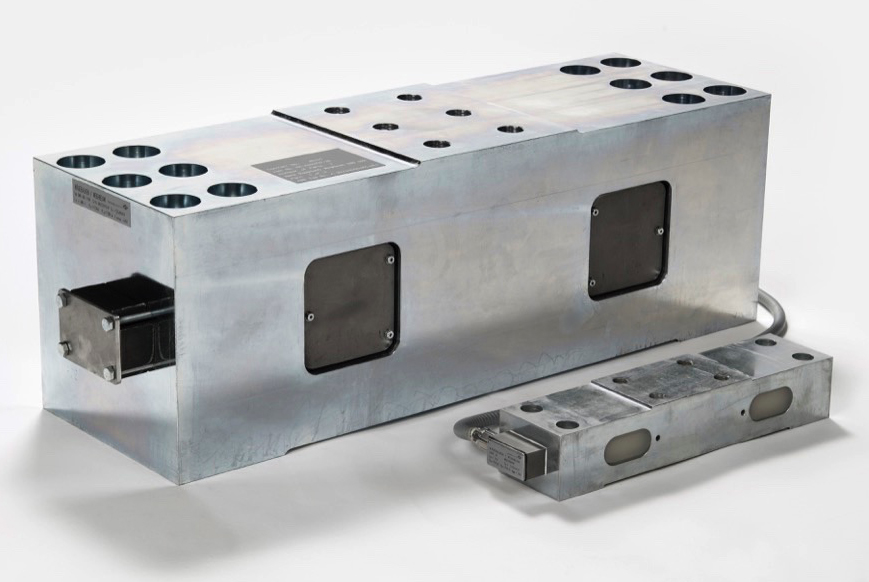

According to Schenck Process, for more than 30 years the company's weighbeams, now all branded SENSiQ WB, have been the standard for tough weighing tasks, especially in the heavy duty and harsh environment of steel production.In addition to its high capacity, the latest SENSiQ WB development is characterized by the following improved technical features:

- expanded operating temperature range between -40°C and 180°C

- high accuracy, which has always been a key benefit of the SENSiQ loadcell generation, has been further improved to an error of +0.07% across the entire load range

- all loadcells of the SENSiQ WB fulfil IP68 requirements according to ANSI/IEC 60529.

Installation of these SENSiQ® WB weighbeams is simple and cost-effective . They connect directly inside the given structure without moving parts and transmit all disturbance forces and moments with minimal measuring value interference. Plus, SENSiQ WB weighbeams function entirely maintenance-free in the harshest conditions, offering high long-term stability and high reproducibility.Typical applications are ladle turret, ladle transfer car, scrap basket, roller table and tundish car scales as well as silo and hopper weighers. The full SENSiQ WB range now includes 11,5 t, 15 t, 25 t, 40 t, 50 t, 100 t, 150 t, 200 t and 600 t rated capacity types. ■