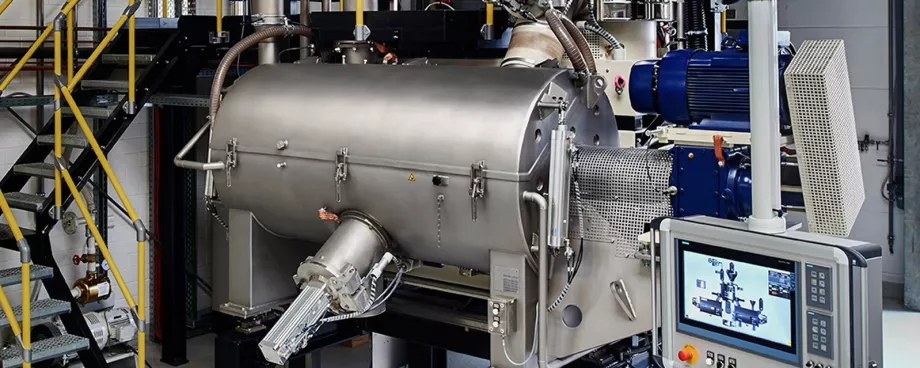

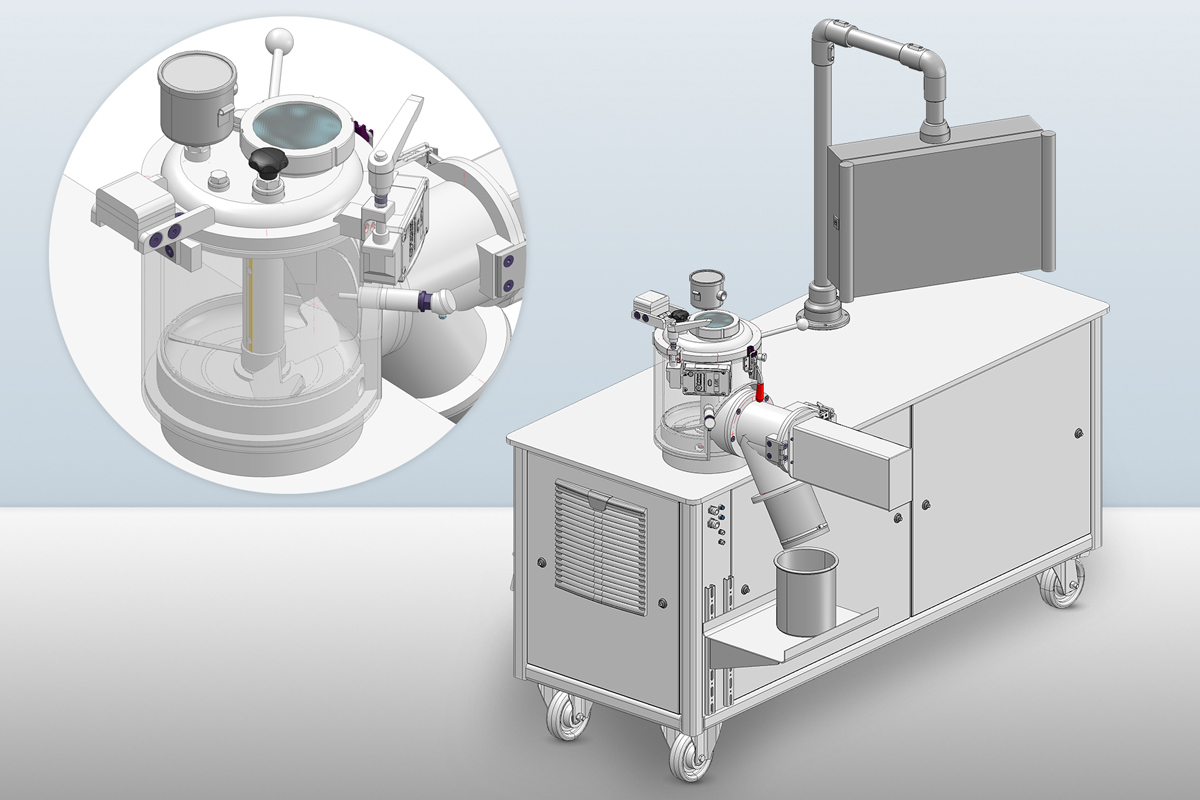

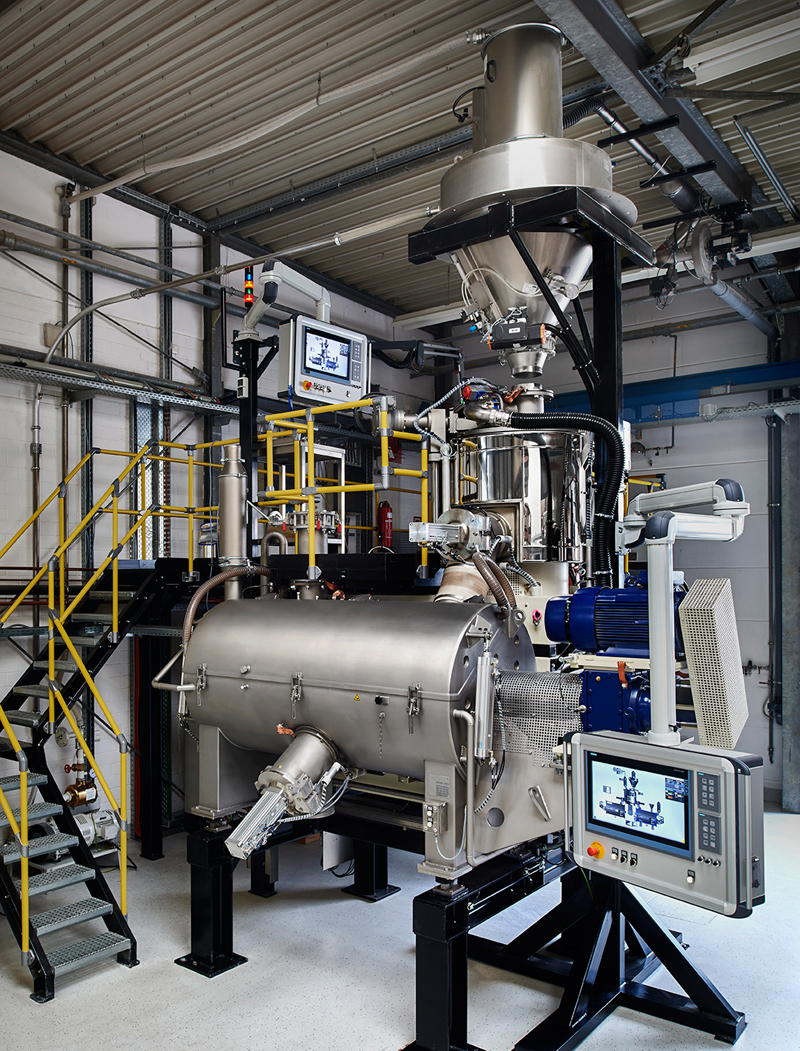

New laboratory mixer for elevated hygiene requirementsThe MTI laboratory mixer premiered at this year's Powtech fulfils elevated hygiene requirements, whether in homogenising different recipe ingredients or as a friction mixer for carrying out thermal processes. The energy input is adjustable over a wide range via the machine's rotational speed and hence, the peripheral velocity of the mixing tool. Moreover, the mixture can be tempered by water via the mixer’s double jacket. Thus, the application range of the new laboratory mixer covers broadly diverse process tasks, including coating, agglomerating and vacuum drying. The food-grade model displayed at Powtech provides a vessel volume of 10 liters at a working volume of 2 to 8 liters. The laboratory mixer’s design allows an easy scale-up to industrial operation for recipes and processes developed to volume production standard. Its outer parts and all surfaces in contact with the mixture are made of stainless steel 1.4541, with the latter industrially ground to a grit 1200 high-quality finish. At a drive capacity of 5.5 kW, the rotational speed of the individually configurable mixing tool can be variably selected between 300 rpm and 3,000 rpm adequate to circumferential speeds between 3.7 m/s and 37 m/s. For additional flexibility in the laboratory the mixer can be moved on casters. As has been standard on MTI products for many years, the new laboratory mixer features a clearly structured touch panel and a Siemens S7 control for manual and automatic operation.Still more versatility in developing for and with customersFor a number of years, MTI – with its excellently equipped in-house R&D Center – has been on record as a particularly efficient partner in the development of tailor-made mixer technology. With its most recent expansion, the company's laboratory provides more scope, e.g., for trials on a larger production scale, as well as a dedicated area for testing under ATEX conditions plus special rooms for mixing products subject to a high contamination risk. Since October 2016, MTI's experienced team has been reinforced by process engineer René Weiffen, who brings additional expertise to the task of resolving R&D challenges for, and with, MTI's customers.

The food-grade model displayed at Powtech provides a vessel volume of 10 liters at a working volume of 2 to 8 liters. The laboratory mixer’s design allows an easy scale-up to industrial operation for recipes and processes developed to volume production standard. Its outer parts and all surfaces in contact with the mixture are made of stainless steel 1.4541, with the latter industrially ground to a grit 1200 high-quality finish. At a drive capacity of 5.5 kW, the rotational speed of the individually configurable mixing tool can be variably selected between 300 rpm and 3,000 rpm adequate to circumferential speeds between 3.7 m/s and 37 m/s. For additional flexibility in the laboratory the mixer can be moved on casters. As has been standard on MTI products for many years, the new laboratory mixer features a clearly structured touch panel and a Siemens S7 control for manual and automatic operation.Still more versatility in developing for and with customersFor a number of years, MTI – with its excellently equipped in-house R&D Center – has been on record as a particularly efficient partner in the development of tailor-made mixer technology. With its most recent expansion, the company's laboratory provides more scope, e.g., for trials on a larger production scale, as well as a dedicated area for testing under ATEX conditions plus special rooms for mixing products subject to a high contamination risk. Since October 2016, MTI's experienced team has been reinforced by process engineer René Weiffen, who brings additional expertise to the task of resolving R&D challenges for, and with, MTI's customers. Ulrich Schär, General Manager at MTI, comments: “With the launch of the new laboratory mixer for particularly exacting hygiene requirements and the ongoing expansion of its R&D capabilities, MTI emphasises its role as a leading innovator in the mixing industry. Already, our standard line-up of machines meets the conditions for integration into Industry 4.0 environments. But we place an equally strong focus on individual developments addressing highly specific customer objectives. With our ambition not to leave any mixing problem unresolved, we have gained a strong market position among the world's leading mixer manufacturers in recent years.”

Ulrich Schär, General Manager at MTI, comments: “With the launch of the new laboratory mixer for particularly exacting hygiene requirements and the ongoing expansion of its R&D capabilities, MTI emphasises its role as a leading innovator in the mixing industry. Already, our standard line-up of machines meets the conditions for integration into Industry 4.0 environments. But we place an equally strong focus on individual developments addressing highly specific customer objectives. With our ambition not to leave any mixing problem unresolved, we have gained a strong market position among the world's leading mixer manufacturers in recent years.” MTI Mischtechnik International GmbH, established in 1975, is an internationally leading manufacturer of mixing and processing equipment for the plastics processing, chemical, food and pharmaceutical industries. With a staff of more than 50 employees working at its headquarters site in Detmold, Germany, the company manufactures mixer systems noted for their outstanding mixing performance as well as energy and cost efficiency. The portfolio includes vertical high-speed mixers, horizontal mixers, heating/cooling mixer combinations, universal mixers, laboratory mixers as well as tailor-made systems. With an export rate of around 80%, MTI Mischtechnik is globally aligned and, as an owner-managed family business, relies on quality that is "Made in Germany".

MTI Mischtechnik International GmbH, established in 1975, is an internationally leading manufacturer of mixing and processing equipment for the plastics processing, chemical, food and pharmaceutical industries. With a staff of more than 50 employees working at its headquarters site in Detmold, Germany, the company manufactures mixer systems noted for their outstanding mixing performance as well as energy and cost efficiency. The portfolio includes vertical high-speed mixers, horizontal mixers, heating/cooling mixer combinations, universal mixers, laboratory mixers as well as tailor-made systems. With an export rate of around 80%, MTI Mischtechnik is globally aligned and, as an owner-managed family business, relies on quality that is "Made in Germany". ■

■

Product News

MTI-Mischtechnik: New laboratory mixer for the foodstuffs and pharmaceutical industries

Detmold, Germany –