Both are designed with just one laser and a number of patented features for maximum durability with minimum maintenance. Installation is easy via plug and play, thorough cleaning without tools with just few simple steps. And the high-performance software – delivered free of charge – offers unique options for evaluation and documentation and meets the requirements of 21 CFR Part 11.

Overview of the main features:

- Two different measuring ranges - perfectly equipped for all measuring tasks

- Ultra-fast measuring times of less than a minute

- Especially quick rinsing – four times faster than usual

- Wear-free and low-maintenance - one professional maintenance per year is sufficient

- Highly accurate measuring results – that exceed ISO 13320

All FRITSCH Laser Particle Sizers ANALYSETTE 22 NeXT are developed according to a smart, modular concept. You only buy what you really need and you can flexibly grow with your sizing tasks.

The Modules

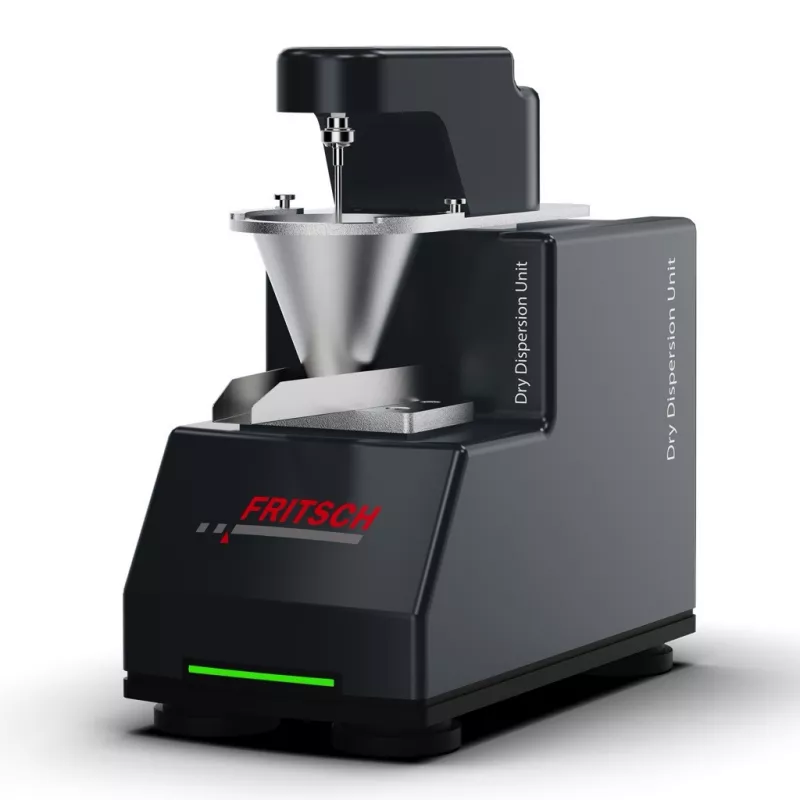

Module Dry Dispersion Unit: It’s height-adjustable funnel and a stirrer made of stainless steel ensure optimum sample feeding adapted to the respective sample material.

Module Wet Dispersion Unit: Fast, uniform distribution of the sample material thanks to the powerful centrifugal pump with adjustable speed.

NEW: ANALYSETTE 22 NeXT dry dispersion unit

|

NEW: ANALYSETTE 22 NeXT wet dispersion unit with pH sensor

|

Module Ultrasonic Box: For even finer adjustment of the wet dispersion to the respective sample – ideal if you frequently measure sample materials that tend to agglomerate.

Module pH Measurement: Simple, continuous monitoring of the pH value of the dispersion liquid covers fluctuations much more effectively than the zeta potential.

Module Extreme Chemical Resistance: The special conversion kit for problem-free measurement when using aggressive organic solvents such as benzene or hexane.

Watch Video

The special features of the FRITSCH ANALYSETTE 22 NeXT and how it works – please have a look:

■