Bucket elevators are playing a standard equipment role in the bulk material conveying technology wherever vertical conveying is involved. In more than 30 years, Aumund continuously refined the bucket elevator technology and offers nowadays strong and most capable solutions for the vertical transport of bulk material worldwide. Their belt bucket elevators are characterised by large conveying heights of up to 200 m and conveying capacities up to 2500 t/h. The new BWG-GK elevator for coarse grain is designed for the transport of material of grain sizes up to 80 mm.

Special Considerations

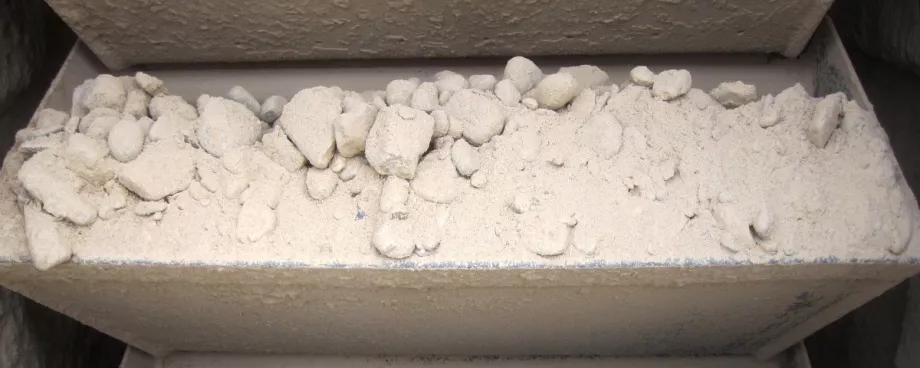

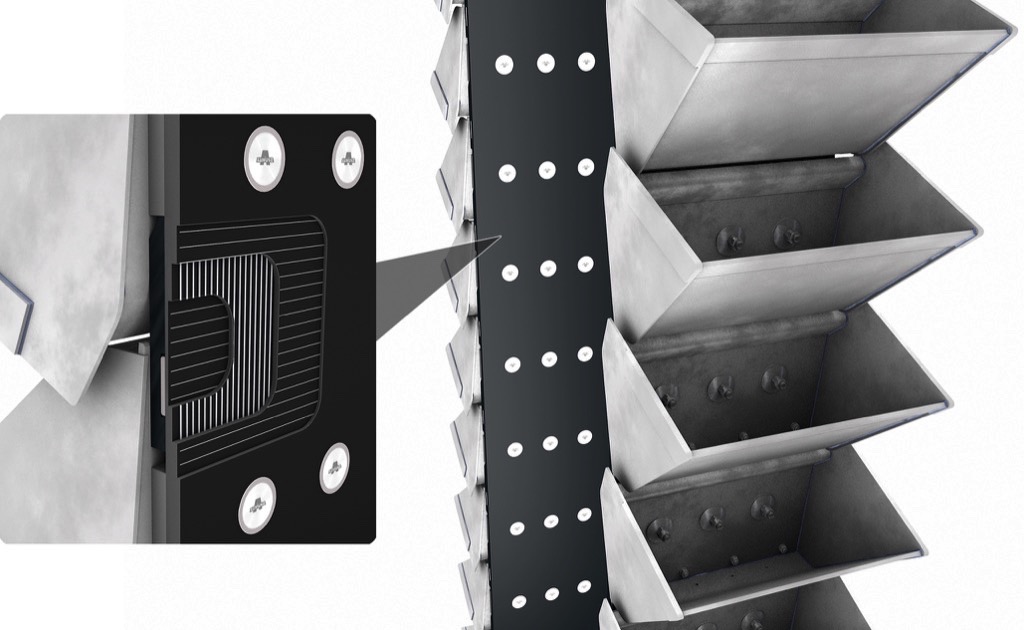

The main task during development of a belt bucket elevator for coarse material is the protection of the belt from damage by the material conveyed. Aumund therefore follows a new path: Due to the narrow, overlapping bucket configuration the belt disappears entirely behind the buckets. It is thus protected and no coarse material can become jammed between the backs of the buckets and the belt. The outer edges of the belt are simultaneously protected. Even in the case of a stoppage with filled buckets, no coarse material will be thrown behind the backs of the buckets.Another task is to ensure a safe bucket attachment and, considering the loading conditions of the buckets, even in case of scooping. Here, the design of the Aumund steel cord belt with transversal steel cord reinforcement provides high pull-out strength and reliable fixing for fastening of the bucket.Specially developed plate screws which differ significantly from conventional DIN plate screws have been designed for longer belt service life and higher carrying capacity. They can only be used for fixation of the buckets. Further attachments to increase the clamping force at the bucket fastening are not necessary. The advantage: the belt runs smoothly and without high abrasion on the drive pulley. Only small dead loads have to be transported.

Furthermore, the belt of a bucket elevator needs to provide high tensile strength, low net weight and low elongation, while simultaneous running in good alignment is demanded. This is achieved by a specialized production process and most of all by a high transversal rigidity. The bucket elevator belt has to be optimally designed for its attachments like buckets, rubber seals and endless splices in order to function as a reliable complete system in daily operation, even after many years. All this is ensured by the carcass construction of Aumunds bucket elevator belts in combination with their unique bucket fastening system. Closely spaced high-tensile steel cords act as continuous tensile members.This enables belt strengths of up to 4200 N/mm for lift heights of more than 200 m. On the front side as well as on the back side of the tensile members steel cord transverse reinforcements strengthen the belt. In contrast to reinforcements with textile fabric inlays, the advantage of steel cord transverse reinforcements is the higher adhesion of the rubber, which ensures the permanent connection of the individual belt layers, even under the influence of temperature.Newly developed rubber compounds based on ethylene propylene diene monomer (EPDM) allow operational ranges up to a material temperature of 150 °C for these belt bucket elevators. Even peak temperatures up to 170 °C may be reached. Load tests under industrial daily routines proved that EPDM-belts are much more resistant to aging than belts made of styrene-butadiene rubber (SBR).

| Aumund Worldwide | |

| The conveying and storage specialists of the Aumund Group are active worldwide. Their technically sophisticated as well as innovative products have contributed to the Aumund Group today being among the market leaders in many areas of conveying and storage technology. Their manufacturing and logistic companies in Germany (Aumund Fördertechnik and Aumund Logistic (Rheinberg), and Schade Lagertechnik (Gelsenkirchen), as well as Samson Materials Handling (Ely, England)), are consolidated under the umbrella of the Aumund Group. In conjunction with the headquarters of the manufacturing companies, the global conveying and storage technology business is spearheaded through a total of eight locations in Asia, Europe, and North and South America. | |

■