Re: Pneumatic Conveying Using Root Blower

Dear ardiadelin,

Would the buffer bin & T pipe enough to reduce the pressure & dust?

A T-pipe does not reduce pressure as the pressure drop over a T-piece is minimal.

The cement and the cement dust go directly into the buffer bin.

From the drawing, all the conveying air is entering the bulk truck from the buffer bin outlet into the bulk truck tank.

The bulk truck tank de-aeration (venting) must be done through a filter, to prevent dust entering the atmosphere and keeping the pressure in the tank close to atmospheric.

A safety valve is also required.

In your design, the loading bellow will act as a safety valve and lift from the loading hole, exhausting the dusty air (probably with cement) into the atmosphere

From the drawing, you are trying to make a bulk truck loading station from 2000-ton silo to the bulk truck.

To keep the pressure in the 2000-ton silo atmospheric, an outlet rotary valve or screw feeder is a must.

The buffer bin is better to be equipped with a filter on top and with a safety valve and level-testers.

To prevent the bulk truck from overloading (as forbidden by road laws), the bulk truck must be loaded on a weigh bridge.

Advise: consult a professional in your neighborhood. ■

Teus

Re: Pneumatic Conveying Using Root Blower

Dear ardiadelin,

Can someone advise me on the root blower capacity (air volume, pressure, kW, rpm) to transfer cement from silo, with scenario as below:-

The combination of a "Roots" blower (PD blower) and a 6"pipe with a length of 79 m will not bring 100 tph

The reason is that a PD lobe blower has a limited pressure drop at 1.0 bar ■

Teus

Re: Pneumatic Conveying Using Root Blower

Thank you for your advise Sir.

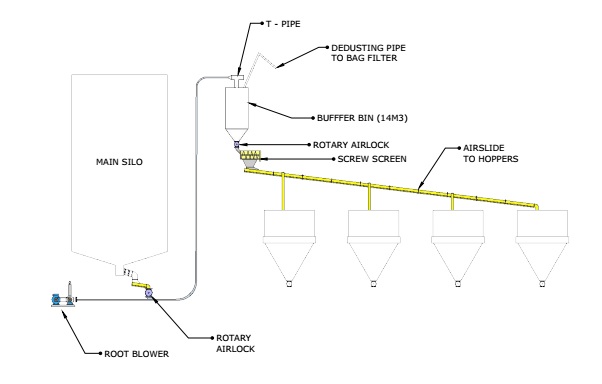

Perhaps i could give you a bigger picture of the whole system. (see the attachement)

The route of pipe shall be the same as previous 79m (3 main elbows).

If the transfer rate to be 50 TPH. How big is the root blower to be used and the pipe diameter size ?

I will be grateful if you advise me. ■

Re: Pneumatic Conveying Using Root Blower

Dear ardiadelin,

Calculating the 6” pipeline for cement with a PD lobe blower (maximum 1.0 barg)

The achievable capacity is just around 50 tph at 0.95 barg.

The used PD lobe blower is then 0.35 m3/sec

However, your installation layout is really for cement.

-The dedusting bag filter should be placed on top of the buffer bin, whereby the cement conveying pipe is entering the buffer bin from the side, underneath the filter.

-The buffer bin requires a filter, safety valve and level testers.

-A screw screen underneath the buffer bin is not required.

-Underneath the main silo, it looks like you have installed a screw screen compactor, (screw feeder) with a rotary valve. It is very doubtful that the cement will flow through the slope pipe towards the rotary valve against the rotary valve air leakage.

-A rotary valve, directly underneath the silo is sufficient. A screw feeder increases the energy consumption of the system.

-All the hoppers require a filter, safety valve and level testers.

As you are obviously designing this system yourself, the advice is: Be careful and consult a professional company which makes that kind of installations.

Attachments

■

Teus

Re: Pneumatic Conveying Using Root Blower

Thank you very much for your advice Teus.

I appreciate your time and attention.

So, does it mean 4 inch pipe is not feasible to be used in this case ?

Let say, the same root blower (6 inch bore) to be used with 4 inch pipe (with reducer), would that increase the transfer rate above 50TPH ?

Thank you. ■

Re: Pneumatic Conveying Using Root Blower

Dear ardiadelin,

So, does it mean 4 inch pipe is not feasible to be used in this case ?

Correct.

Let say, the same root blower (6 inch bore) to be used with 4 inch pipe (with reducer), would that increase the transfer rate above 50TPH ?

The 4” pipe diameter is the bottleneck.

100 tph requires a bigger pipe than 4” and a bigger compressor than 0.35 m3/sec, to maintain the proper air velocity. ■

Teus

Re: Pneumatic Conveying Using Root Blower

Teus

Re: Pneumatic Conveying Using Root Blower

Hi Teus,

Based on the same design, for the airslide conveying system (transfer rate 50TPH), total length around 35 meter.

Proposed size of airslide to be 30cm width x 35cm depth. Using centrifugal fan blower.

What centrifugal fan capacity would be suitable to achieve 50TPH ? Pipe bore/ dia. for the air pipe ?

Thanks for your advise. ■

Re: Pneumatic Conveying Using Root Blower

Dear ardiadelin,

For a cement air slide, the mean air velocity through the total fabric surface is usually approx. 0.05 m/sec.

The required fan pressure is depending on the fabric cloth air resistance and the cement height in the airs slide plus the pipe length resistance between the fan and the air slide. Normally between 4000Pa to 5000 Pa.

The pipe velocity is usually chosen at 20 m/sec to 25 m/sec.

I still want to emphasize:

Be careful and consult a professional company which designs and makes that kind of installations for the requirements you have.

Air slides are easily available on the market from well known manufacturers and therefore it is a waste of time and money to go on your own steam in such cases.

Also see:

http://www.pneuvay.com.au/pneumatic-...es/#main-view/ ■

Teus

Pneumatic Conveying using Root Blower

Hi All,

Can someone advise me on the root blower capacity (air volume, pressure, kW, rpm) to transfer cement from silo, with scenario as below:-

Transfer rate 90-100 TPH

Bore 4 inch or 6 inch

Pipe Length 6 m Hor ; 35 m Ver ; 38 m Hor

Bend - 3 pcs

At the end of the pips is 14m3 Buffer Bin with T pipe (blinded one side) on top.

Would the buffer bin & T pipe enough to reduce the pressure & dust ?

Thank you for your time.

Picture attached

href="https://forum.bulk-online.com/attachment.php?attachmentid=48081&d=1589309702" title="Name: pneumatic trasnfer.jpgViews: 80Size: 20.9 KB">pneumatic trasnfer.jpg ■