A Radius Is Smooth

Dear Mr. Guerrero,

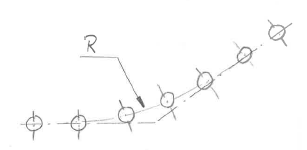

usually the transition is done by implementing a radius to the belt line.

The radius R is calculated dependant upon belt properties, belt tension / loading, troughing and idler design.

This needs to be done by a specialist of bulk material handling / conveyor design.

Regards

R. ■

Re: Problem - Conveyor Belt Without Smooth Transition

Without seeing drawings & knowing the design intent of the conveyor it is impossible to give you an accurate solution. But along the lines that Roland is correctly directing you, is it possible to install enough shimming stools (stands) for the idlers to accommodate the necessary concave curve? As Rowland says this information and solution is best to be completed by a design firm that understands the requirements. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

The Customer Is Always Down...Right

We are somewhat in the dark here:

What is the throughput;

What material;

Belt width;

Conveyor lengths involved;

Filling factor;

Speed;

Reason for no vertical curve.

You might care to speed the belt up and put a couple of very smallest pulleys very close together: rather like an ultra compact tripper. Then you would have to establish a condition of no fall back or run back. Your customer clearly has no idea: so anything is possible. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Problem - Conveyor belt without smooth transition

Hello to all!

I'm new here and this is my first discussion.

Our company is a distributor of conveyor components in Mexico.

We have a customer who is having problems to lie down or keep the belt conveyor on the idlers rolls. The issue is that the conveyor change its inclination without smooth transition from 0° to 20°, causing spillage of material from the sides of the conveyor. He’s currently using special conveyor rubber wheels to accommodate and press down on the conveyor belt. However our customer is asking us for a modern and efficient solution.

Can somebody help me about its own personal experience and give me an idea?

Thanks ■