Consider A Sandwich Belt High Angle Conveyor

In an Iron Ore Concentrate Plant, We intend to use bucket elevator. However, we are worried about material moisture content. Have you some previous experience (probable difficulties, solutions, advises, etc) on the matter? Iron Ore Concentrate Plant with similar moisture will be really helpful.

Material: Iron Ore Concentrate (very abrasive)

Material size: K100< 1mm and K80< 0.1mm

Moisture content: 7% to 9%

Design capacity of material handling system: 1000 t/hr (dry basis)

Elevation lift: about 40m

Site condition: min. temp. -15C, max. temp. +45C, altitude 1250m

Thank you for your help.

Alireza,

Have you considered the use of a DSI Sandwich Belt High Angle Conveyor? If you'd like to explore it's cost savings use, please contact me at aduncan@dossantosintl.com.

We would be happy to offer you a budget quote.

Regards,

Amy D. Duncan ■

Barge Poles Ahoy!

If you put moist ore into a bucket it will stick like the proverbial blanket effect. That means you will be recycling a considerable quantity continuously. Is this include for in the design. Besides that situation there is the issue of debris falling past the discharge chute and periodically clogging the casing and boot.

The only justification for a bucket elevator is where the process people have overlooked something and run out of space.

Obviously this happens all the time. It looks like there will be 2 more, according to your management. Why 2? You will need a standby to work those replacement periods after the ore paste has ground through the elevator. Nice business to do people with. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

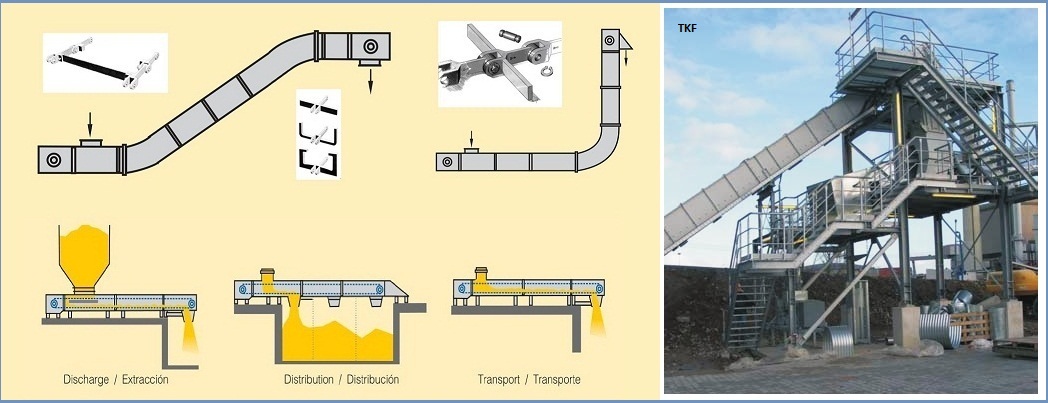

With Enough Moisture --≫ Chain Conveyor

In an Iron Ore Concentrate Plant, We intend to use bucket elevator. However, we are worried about material moisture content. Have you some previous experience (probable difficulties, solutions, advises, etc) on the matter? Iron Ore Concentrate Plant with similar moisture will be really helpful.

Material: Iron Ore Concentrate (very abrasive)

Material size: K100< 1mm and K80< 0.1mm

Moisture content: 7% to 9%

Design capacity of material handling system: 1000 t/hr (dry basis)

Elevation lift: about 40m

Site condition: min. temp. -15C, max. temp. +45C, altitude 1250m

Thank you for your help.

In case your ore is wet enough it will stick together, at least bad enough to make it difficult to purge out of buckets BUT GOOD enough to be lifted vertically with an chain conveyor. But this also means that in the future you do not have to dry your ore before lifting it.

See two pictures:

In case somebody is interested we could sugest some equipment

Give us your feedback

rgds

dak

T +1858 5644045

M +54911 53252311

E bulk.good.solutions@gmail.com ■

Bucket Elevator for wet Iron Ore Concentrate

Dear experts

In an Iron Ore Concentrate Plant, We intend to use bucket elevator. However, we are worried about material moisture content. Have you some previous experience (probable difficulties, solutions, advises, etc) on the matter? Iron Ore Concentrate Plant with similar moisture will be really helpful.

Material: Iron Ore Concentrate (very abrasive)

Material size: K100< 1mm and K80< 0.1mm

Moisture content: 7% to 9%

Design capacity of material handling system: 1000 t/hr (dry basis)

Elevation lift: about 40m

Site condition: min. temp. -15C, max. temp. +45C, altitude 1250m

Thank you for your help. ■