Steel Rollers

RULMECA Steel rollers - PSV SERIE

Typical application for the PSV rollers are: mines, quarries, cement plants, coal-fired power plants, port installations.

The effectiveness of the PSV roller sealing system provides the solution to the environmental challenges of dust, dirt, water, low and high temperatures or applications where there is a large temperature gap between day and night. The working temperature, with standard greased components is defined as between -20°C and + 100°C. It is possible to reach temperatures outside of this range using special grease, bearings and seals.

Steel rollers - Series MPS

For medium duty conveyors at high and medium speed shaft diameter 15 and 20 - tube diameter from 50 to 108.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Rollers And Stations

ROLLERS-STATIONS

With an experience of more than 45 years in belt conveyors applications, Rulmeca has been constantly increasing its product range and developing solutions to meet any specific application need; in other words, a constant evolution.

The state-of-the-art techniques used in design and construction means that top performance levels are granted even in the heaviest operating conditions.

Conforming to the UNI-DIN, ISO, AFNOR, CEMA and BS standards Rulmeca products are used in countless different sectors, such as mining, cement, steel works, glass, chemicals and fertilisers industries.

The Rulmeca Group product range includes Precismeca rollers and garlands, globally well known for their reliability even in the heaviest operating conditions.

Rulmeca rollers are available for belt widths up to 3.000 mm, in diameters 63, 76, 89, 102, 108, 114, 127, 133, 140, 152, 159, 168, 194 and 219 mm – shafts: 15, 20, 25, 30, 40, 50, 60 and 90 mm. Rulmeca offer all the types of stations: carrying troughing sets, impact stations, return stations, self-aligning troughing sets, garlands.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Thermoplastic Rollers

TOP new thermoplastic roller

A light, strong, eco-friendly solution from Rulmeca

Rulmeca is proud to introduce the new TOP roller, a totally thermoplastic roller with the exception of the steel in the ball bearing and the shaft.

The new TOP roller has a lower weight with respect to a steel roller (about 50%), which means a lower power consumption during start/stop operation of the belt conveyor and therefore reduction of power requirements on the plant, easier mounting/maintenance operations, preventing back injuries of the operator and guaranteeing a safer intervention, especially in application where roller mounting or replacement might be critical (suspended belt conveyor, difficult access, long conveyors…), easier/cheaper transportation.

Furthermore the low level of abrasion and corrosion of this roller (wear resistant) guarantees a longer life of the roller and a lower maintenance of the whole plant.

The TOP is belt friendly, since HDPE tube will not wear the belt high resistance to chemical agents. It doesn’t rust, it is suitable for a wide variety of applications and it has a low noise emission (due to thermoplastic noise absorption).

Thanks to the self-cleaning roller surface, there is a prevention of build-up of material, main cause of belt mis-tracking, and less spillage from the belt.

The roller low running resistance sealing system means a lower motor torque need in conveyor starts, a lower motor power size, a reduction of energy consumption of the belt conveyor (added effect to that of the lower weight) and a lower belt consumption.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca - Precismeca Heavy Duty Rollers

PRECISMECA - MONTAN / RULMECA GROUP Heavy Duty Rollers

are designed for heavy duty open mining applications. Thanks to the high quality machined parts & a non contacting multi-chamber labyrinth seal, the rollers run with a wisper. The high quality machining process is a guarantee for a long service life of the PRECISMECA - MONTAN Rollers - 8 years in operation 24 hours a day is not a rarity.

The heavy duty PRECISMECA -MONTAN / RULMECA GROUP - rollers assembled with bearing sizes 6308 - 6312 can be used on high powered belt conveyors with a large amount of line loads.

The mounting dimensions (roller length and axle end) are mainly constructed acc. to DIN 15207 with the geometry's. ( A2, B2, G1 and G2 ).

Other axle end geometry's acc. to DIN 15207 as well as roller length, types of rubber lagging or special options are available on request. Different types of fastening elements, bigger bearing sizes, assembly variants or suspension variants are also available on request.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Motorized Pulleys

Rulmeca Motorized Pulleys:

your reliable partner

The Rulmeca Motorized Pulleys have a long history to tell.

It goes back to the 1950’s when the product was developed in Germany and Denmark as an efficient belt conveyor drive solution.

Since the early 90’s the research & development, engineering and manufacturing of the Motorized Pulley range was centralized in Aschersleben, Germany, at what is today the Rulmeca GERMANY GmbH plant.

RULMECA is a family owned, worldwide Group of Companies, with headquarters in Italy and specialising in the development, production and sales of belt conveyor rollers/idlers, motorized pulleys, fabricated pulleys and other components for the global bulk handling industry.

Rulmeca are working internationally with leading OEM’s, Engineering Companies and End Users supplying products into major applications within the handling of bulk materials such as; coal and lignite mining, cement, quarries, tunnelling, power plants installation, ports, salt and fertilisers, sugar plants, recycling and demolition, crushing and screening etc...

More than half a century of experience in supplying high quality and reliable belt conveyor solutions for bulk material handling equipment is at your disposal.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

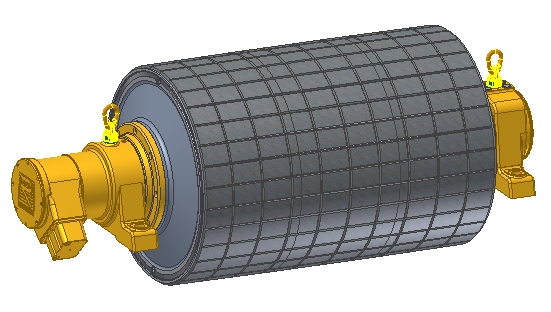

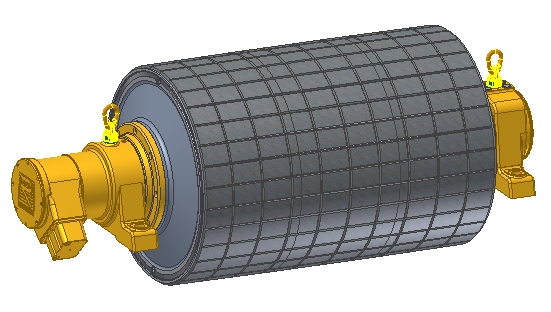

Motorized Pulleys 100hd

Motorized Pulley 1000 HD, Ø 1000 mm

The RULMECA motorized pulley type 1000HD is a highly developed reliable and strong drive with an outstanding power range of 160 – 250 kW.

It is able to take a high radial load and robust in design.

Therefore it is especially developed for use in:

- Mining conveyors,

- Excavators,

- Stackers,

- Reclaimers,

- Heavy loaded conveyors in gravel and sand

The motorized pulley 1000HD is designed for tough, irregular, extreme and brutal working condition.

The compact design allows the design engineers to save material and cost when developing the conveyor.

A high protection rate connected with the standard labyrinth sealing system it can be used in all ambient conditions.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Belt Pulleys

RULMECA belt pulleys presented on our web site combine experiences from different companies-Rulli Rulmeca and Rulmeca GERMANY which are working as one group today.

RULMECA GERMANY with a long experience as a developer and manufacturer of bulk conveyor components became a partner of the Interroll Group in 1991.

Interroll as a well known manufacturer of unit handling products was able with the Forder-und Antriebstechnik to open a bulk business unit at that time.

In July 2003 the Forder-und Antriebstechnik GmbH in Aschersleben, Germany, where belt pulleys have been produced for many years, was purchased by Rulli Rulmeca Spa Italy along with the products and the knowledge of developing & producing bulk conveyor components.

The Forder-und Antriebstechnik, today renamed RULMECA GERMANY GmbH, was now back in a business field of a well known manufacturer of bulk handling products.

In 2004 Rulli Rulmeca Spa the mother company of the RULMECA Group in Italy decided to establish the belt pulley centre in RULMECA Germany.

RULMECA GERMANY is designing and manufacturing pulleys, using materials of the highest quality in a production process employing advanced technology.

This together with the application of the Quality Assurance system certified to ISO 9001:2000, contributes to the production of high quality products offering dependable, long life performance in the field and appreciably reducing maintenance cost.

Each RULMECA conveyor pulley is individually computer designed to meet the client's requirements. Design is based on the predetermined tolerances of stress loading and the distribution of load through the individual components of the conveyor pulley, within the critical calculation of fatigue factors.

Bending and shear stresses are limited in the design of drive and non-drive shafts together with the deflection of the shaft at the conveyor pulley disc.

RULMECA have a deep understanding of the precise calculation of all stress potential and the matching performance of components and constituent materials.

The skills and experience of RULMECA are assisted by,the latest in computer aided technology and manufacturing techniques employed with the high level of control available only to a complete in-house production unit.

In the following drawings various arrangements of traditional belt conveyors are shown, with the pulleys numbered and described according to their function and position in the belt conveyor layout.

1 - drive pulley;

2 - return pulley;

3 - return pulley;

4 - bend pulley pulley;

5 - tensioning pulley;

6 - snub pulley

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Components: Belt Cleaners And Covers

RULMECA components: belt cleaners and covers

In the project design of a belt conveyor, after having defined the components of primary importance, it is important to consider other accessories such as belt cleaners and covers for the conveyor.

Covers

The necessity to protect belt conveyors may arise from the weather, from the volatile characteristics of the conveyed material, or from the type of works plant, and also from European norms that require the covering of the total length of a belt conveyor.

Rulmeca covers do not require maintenance and are very easy to install and move around. There are two styles of covers that are proposed : those in preformed PVC and those in corrugated galvanised sheet steel.

Belt cleaners

The use of cleaning equipment has become an indispensable requirement to assure general plant efficiency and to reduce the periods of service needed for maintenance.

There has been a notable development of this equipment in recent time for differing reasons: prolonging the life of the conveyor; limiting the deterioration of the belt, improving the energy efficiency of the installation, reducing loss of material thereby increasing the load capacity, eliminating a major cause of wear on the return rollers.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Products For Power Stations

Power Stations

Many power stations are located at ports. The transportation of coal and other products within a sea-marine environment requires carefully selected rollers and drives to ensure the application will enjoy years of maintenance free product performance. Rulmeca have for decades been one of the key suppliers of Rollers and Motorized Pulleys to Power Station projects on a global basis. The protection and sealing systems of the Rulmeca rollers and motorized pulleys are second to none and provides the system integrator as well as the end-users with a product life time that meets and exceeds expectations.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

1allegato-power-stations[1] (PDF)

■

Rulmeca Products For Mining & Quarrying

Mining & Quarrying

The mining industry in general has seen new growth driven largely by new demands from various parts of the world. For many years Rulmeca have been a key supplier of products to various different mining projects handling iron ore, copper, limestone, granite, salt etc. Working closely with the different end-user industries and mines we have gained valuable knowledge during the years. It is this experience that we have used in developing and improving our products. Close co-operation with both system integrators, OEMs and End-User ensures that we are able to specify the product most suitable for each application. One example is the ATEX certification of our products.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Products For The Cement Industry

Cement

Our rollers and motorized pulleys have been used within the cement, concrete and batching plant industry for more than forty years. We are partnering some of the largest producers of new plants and working with large end-users to ensure we are kept up to date with the requirements from the industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

cement,concrete-beton[1] (PDF)

■

Rulmeca Products For Salt And Fertilisers Industries

Salt & Fertilisers

Rulmeca are working frequently with projects for fertiliser and salt handling. Rollers in plastic or steel are securely protected against corrosion. Our Motorized Pulleys IP66/67 in stainless or partly stainless steel with regreaseable sealing systems are being used in Salt and fertiliser industries - 24 hours a day without maintenance problems. The selection of the right drive or rollers is of key importance and Rulmeca have the experience to assist you in your choice.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=rulmeca+site%3Abulk-online.com&btnG=Suche&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Products For Crushing & Screening

Crushing & Screening

The Rulmeca Group provides the ideal partnership with many manufacturers of Crushing and Screening Machinery. Whether the machinery is stationary or is used as mobile units Rulmeca offer solutions to almost all applications - and in fact has been doing this for many years. The large standard range of rollers accompanied by our motorized pulleys, drive and tail pulleys and belt cleaners, ensure that the manufacturer can work with Rulmeca for the complete package of products.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

Rulmeca Products For Special Applications

Special applications

Rulmeca are constantly being challenged by our customers to discover solutions to diverse applications. They may be new applications or simply just to provide products to withstand aggressive and extreme applications in the form of temperatures, environments, loading, speed etc.

These are day to day issues and with our many years of experience we have resolved and supplied to almost all industrial applications.

Rollers and motorized pulleys in steel, different grades of stainless, with re-greasable sealing systems with a selection of tube, shafts and bearings to cover any thinkable demands. We are well suited to help you resolve any special application problem you may have.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1563-rulmeca-group.htm" target="blank">https://edir.bulk-online.com/profile...meca-group.htm

href="http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

■

The RULMECA GROUP

The RULMECA GROUP

We are the worlds leading manufacturer and supplier of rollers, motorized pulleys and components for the global bulk materials handling market.

RULMECA is a worldwide Group of Companies, specialising in the production of rollers/idlers, motorized pulleys, fabricated pulleys and other components for the worldwide bulk handling industry.

The Rulmeca Group's strenghts include:

- Wide distribution networks in countries with a strong tradition in bulk handling due to their mining and quarrying activities;

- Close relationships with customers and professional services;

- Manufacturing flexibility;

- Range of products focused on the needs of the bulk materials handling industry;

- A continuously expanding and evolving product range;

- Constant improvement in technical, design, and sales services;

- A global market reach thanks to 10 manufacturing companies, 7 sales companies and 2 representative offices (Russia and Kazakhstan) with a total of 1100 people employed;

- A network of skilled agents ready to meet the needs of the market on a timely basis.

For more information, please visit:

https://edir.bulk-online.com/profile...meca-group.htm

http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Attachments

cartina-group2 (JPG)

rulmeca (JPG)

■