General Requirements

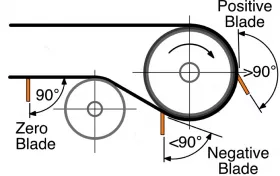

A discussion about belt cleaner tensioners must include the basic approaches to belt cleaning, as the most effective approach is achieved through a combination of cleaner and tensioner designs. Industry has gravitated toward mechanical cleaners and tensioners because they are simple and economical. The most common mechanical belt cleaner designs present a blade or brush at various angles to the belt. Depending on the cleaner type and materials of construction, they can approach the belt at either a positive, negative or zero rake. [Fig.1]

Regardless of the basic cleaning approach, maintaining the optimum range of contact pressure will result in the best balance between cleaning performance, cleaning element wear, belt wear and power requirements. CEMA Standard 576, Classification of Applications for Bulk Material Conveyors Belt Cleaning, provides a performance-based classification system for use in specifying belt cleaners.

Basic Approaches to Tensioning

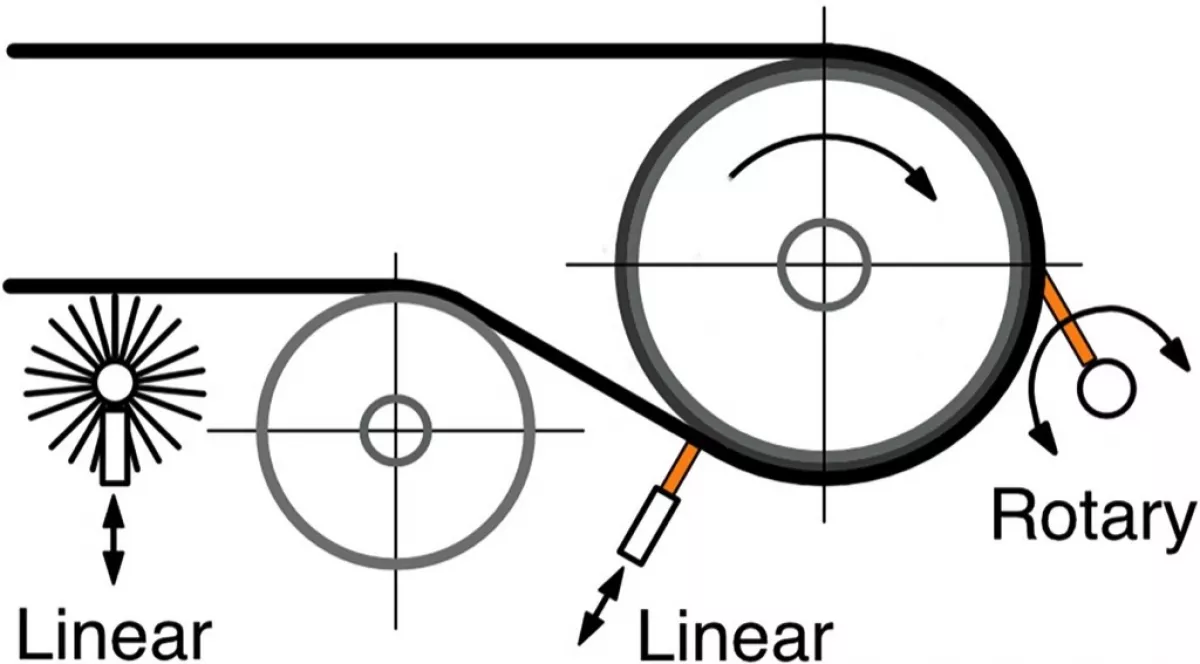

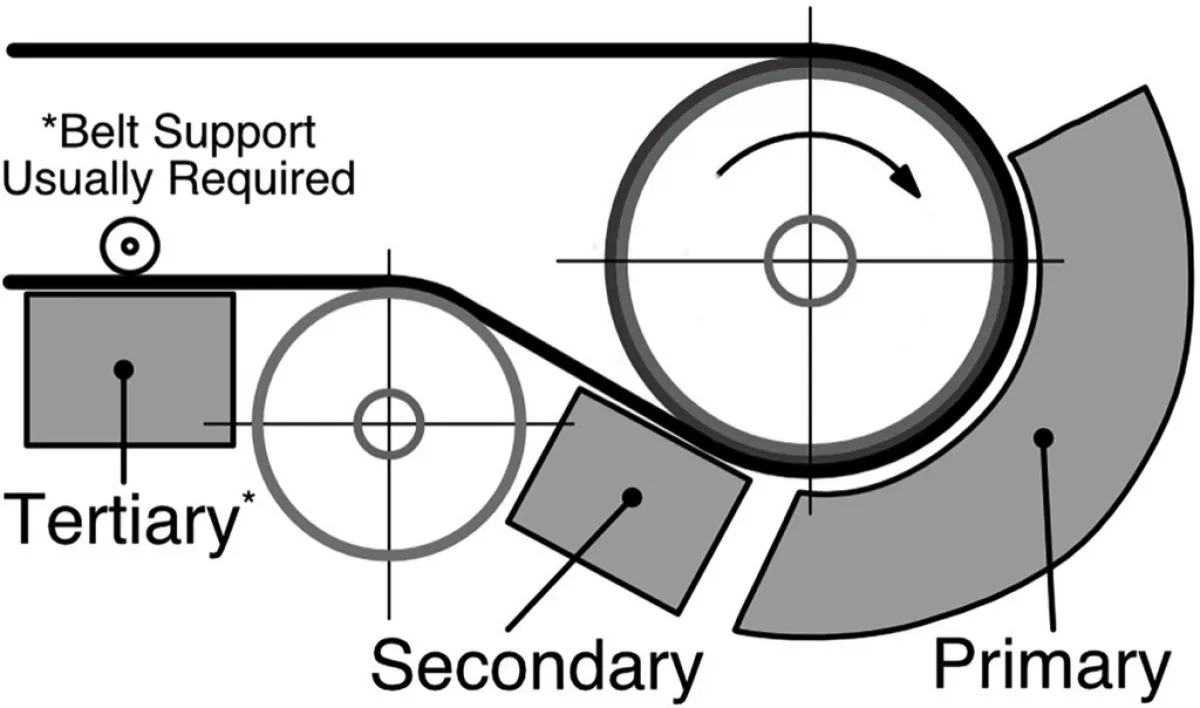

There are two basic approaches to applying tension to the belt cleaner: linear and rotary. [Fig.2] The blade’s angle of approach to the belt often dictates whether a linear or rotary tensioner is applied. The stored energy that creates the tensioning force most often comes from gravity, springs or actuators. CEMA defines the cleaning positions as Primary, Secondary and Tertiary. [Fig.3] Most belt cleaners mounted in the primary position utilize a rotary style tensioner, while most belt cleaners mounted in the secondary or tertiary positions use linear style tensioners.

Linear Tensioners

Fig. 2: Basic tensioning approaches

|

Fig. 3: CEMA-defined cleaning positions

|

Linear tensioners are most often applied where the compensation for wear is required in small increments, such as with hard metal-tipped cleaners located in the secondary cleaning position or with brush cleaners. The basic tensioner design approach is typically a carriage that constrains the support frame but allows linear movement along a guide or guides roughly perpendicular to the belt surface, with the support frame and blade design providing the cleaning angle. Some designs incorporate a relief ability for impact by splices or belt defects.

The advantages of linear tensioners include:

- simple in design;

- can be engineered to one setting for full blade wear;

- access windows are easily incorporated within the mounting footprint;

- can accommodate actuator deflection scales for accurate adjustment of cleaning pressure and;

- delivers the ability to adjust for uneven mounting positions or asymmetrical blade wear.

The disadvantages of linear tensioners include:

- the tensioner footprint can be large, restricting options for ideal belt cleaner installation;

- there must be access to the far side for adjustment;

- the guide mechanisms are subject to fouling from dust and corrosion and;

- changing from bottom adjustment to top adjustment or providing for adjustment from one side complicates the tensioner design.