(From the archive of ”bulk solids handling", article published in Vol. 34 (2014) No. 3 , ©2014 bulk-online.com)Approximately 20 grams of gold, 200 to 300 grams of silver, as well as platinum and other precious and non-ferrous metals: this multitude of resources can be hiding in one tonne of heavy non-ferrous fraction. In the recycling process for automobile, electrical and electronic waste, the coarse components are shredded and treated, leaving this fraction behind.Despite its great value, this fine material is usually disposed of at landfills or incinerated. As more and more electronic components and boards are used in vehicles and electronic devices, all the more valuable resources are lost.With its complete solution for the fine treatment of shredder residues, BHS picks up where others have left off: substances once headed to the landfill or incinerator are now fed back into the material cycle and profitably recycled. Operators re-port that the sale of the materials, for example the heavy fraction of non-ferrous metals, earns them approximately EUR 3500 per tonne, and that their plants have paid for themselves within nine to twelve months.However, the plant does not just generate income from the sale of metals; it avoids landfill costs as well. In turn, this serves to unburden landfills, which is all the more significant in light of the new landfill directive. When compared to other systems, rotor impact mills for recycling applications (type RPMV) also feature low wear-related costs, contributing in large part to low costs of operation.

Utilisation of Secondary Raw Materials

Shredding used to be of commercial interest mainly for ferromagnetic materials. Nevertheless, by the end of the last century, the recycling of non-ferrous metals also became economically viable. Today, with modern plant technology, the sale of precious metals is lucrative as well. The German manufacturer BHS was one of the pioneers in this development with a one-of-a-kind machine: the rotor impact mill (RPMV). Supplied exclusively by BHS worldwide, it has been among the key solutions for the clean separation of non-ferrous metals from other materials.Building on its scrap crushing expertise and with many of its rotor impact mills integrated in similar processes, BHS has developed a complete solution for fine-grain treatment. It combines impact crushing technology with physical separation methods and comprises all process stages from the feeding of material to the separation of individual substances to the removal of dust.

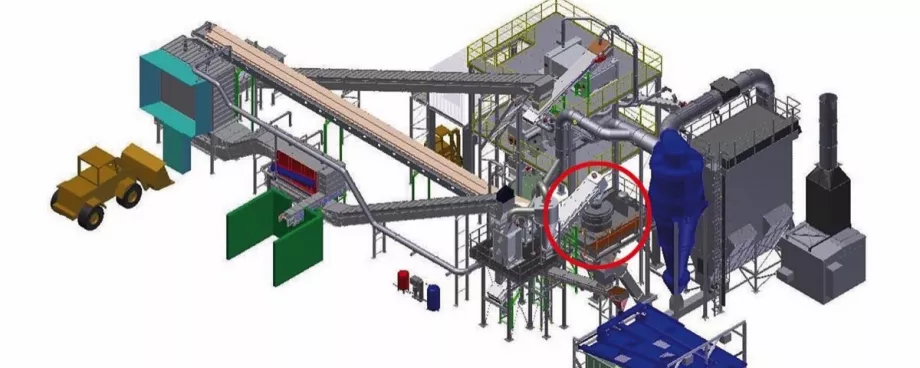

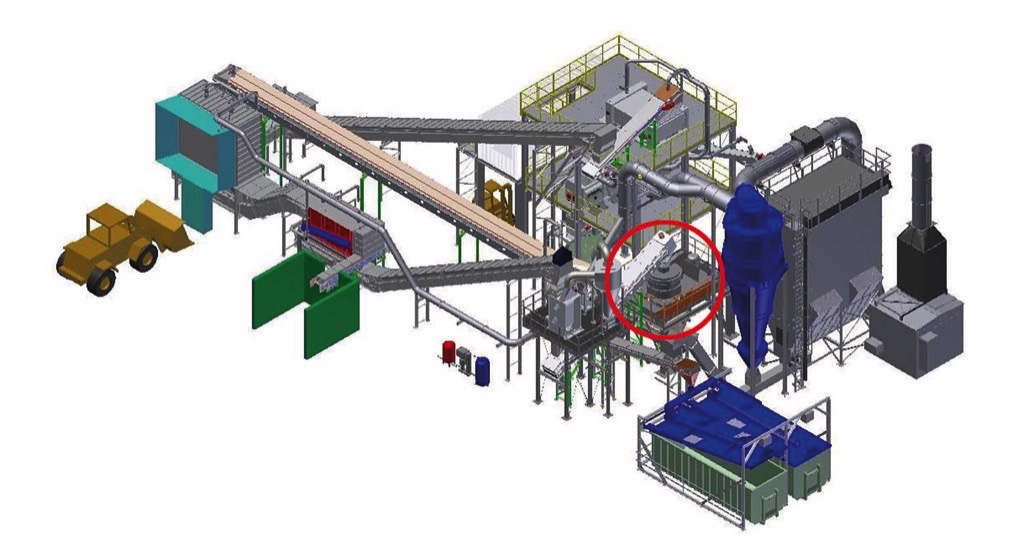

Layout of the Recycling Process

In the first part of the process, the input material is crushed and the lightweight materials are separated. In the second stage, the remaining material is screened and sorted by density. The final products are thus various materials and metal fractions cleanly separated according to type and grain size.

The centerpiece of the plant is the rotor impact mill of type RPMV. It crushes the brittle-hard materials and shapes the ductile, metallic ones into balls. The standard plant, which BHS offers as a complete solution, achieves a throughput of approximately 10 tonnes per hour. In addition, BHS will also design larger plants which are tailored to specific customer requirements.

Mechanical Crushing

To begin with, coarse materials with a grain size of over 20 mm are screened, and lightweight materials such as foam, textiles or plastics are separated and freed from dust by means of a zig-zag separator. The dust is conveyed to a covered container.

The remaining material (grain sizes between 0 and 20 mm) is crushed and disaggregated in the rotor impact mill. The machine works selectively here: brittle materials – for example mineral substances, glass or castings – are finely crushed and the composites are separated, while elastic materials such as rubber remain intact.The key effect of the sorting is that ductile metals, i.e. those which can be deformed plastically, are shaped into balls in the rotor impact mill. This is why the machine is also referred to as the “ball shaper”. It lays the foundations for the next stage, which cleanly separates the non-ferrous metals from the other materials. In order to be separated and conveyed to the downstream process stages, the non-ferrous metal parts, which are often long and flat, should have as compact and spherical a form as possible.Every batch is passed through the mill several times; lightweight material and dust are separated out and discharged before the mill prior to each step. The speed of the rotor and the number of cycles can influence the crushing performance of the machine.

Separation

After the last cycle through the rotor impact mill (RPMV), the material passes through a hopper into a screening machine, which separates it into the three fractions. Each of these is then sorted by gravity separation into heavy and light fractions. The heavy fraction containing metallic components is conveyed to magnetic separators and split into magnetic and non-magnetic metal fractions.The non-ferrous metal fraction can be screened again and separated into heavy and light components. This creates two non-ferrous fractions, the light fraction containing light metals such as alumini-um or magnesium and the heavy fraction containing copper and brass, for example.The individual batches are decoupled with two hoppers – one in the circuit above the rotor impact mill and one before the separation stage – allowing for virtually continuous operation. As the rotor impact mill runs, one batch is prepared in the mill circuit and another is screened and sorted.

Cleanly Separated Materials

At the end of the process, all of the fractions are cleanly separated in bins. In addition to proportions of the precious metals mentioned above – gold, silver and platinum – the fraction of non-ferrous metals contains considerable amounts of aluminum, copper and brass, which can also be sold. Depending on the composition of the waste material, the BHS fine treatment plant recovers between five and seven percent of this input as saleable non-ferrous metal.

The result: non-magnetic metals with a grain size of 0 - 3 mm.

|

The resulting product: ball-shaped copper.

|

A positive cost factor is that the whole process is to a large extent automatic and the entire plant can be controlled and monitored by just one employee. An additional employee spends about half of his working hours on the material logistics.

The BHS Rotor Impact Mill

The BHS rotor impact mill for recycling applications (type RPMV) is absolutely unrivaled with its horseshoe-shaped hammers. It contains a plate to which the hammers are attached. The input material is fed into the machine from above through the centrally-located feed tube. When the material hits the rotor, it is accelerated outward at high speed by the centrifugal forces, where it is then caught by the horseshoe-shaped hammers, which impel it against the anvil ring of the outer wall. The impact breaks the input material into pieces.Repelled by the anvil ring, the material hits the hammers again, is further crushed or shaped into balls, and thrown back against the anvil ring. This repeats until the material is small enough to pass through the gap between the rotor and the anvil ring, and falls out through two discharge ducts.

The gap between the horseshoe hammers and the anvil ring is adjustable and the peripheral speed of the rotor is variable, making the BHS rotor impact mill flexible for use in a wide range of applications.The hammers can be manually removed, installed, or adjusted without tools. The virtually constant gap between the anvil ring and the hammers ensures a consistent quality of the final products over the whole service life of the wearing parts. The entire inlet cover can be pivoted for optimum accessibility, which greatly simplifies maintenance of the machine.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2014.

| About the Authors | |

| Alfred WeberSales Manager Recycling/Environmental TechnologyBHS-Sonthofen GmbH, Germany | |

| Ivan GlamuzinaProject Manager, Comminution and Recycling TechnologyBHS-Sonthofen GmbH, Germany |

■