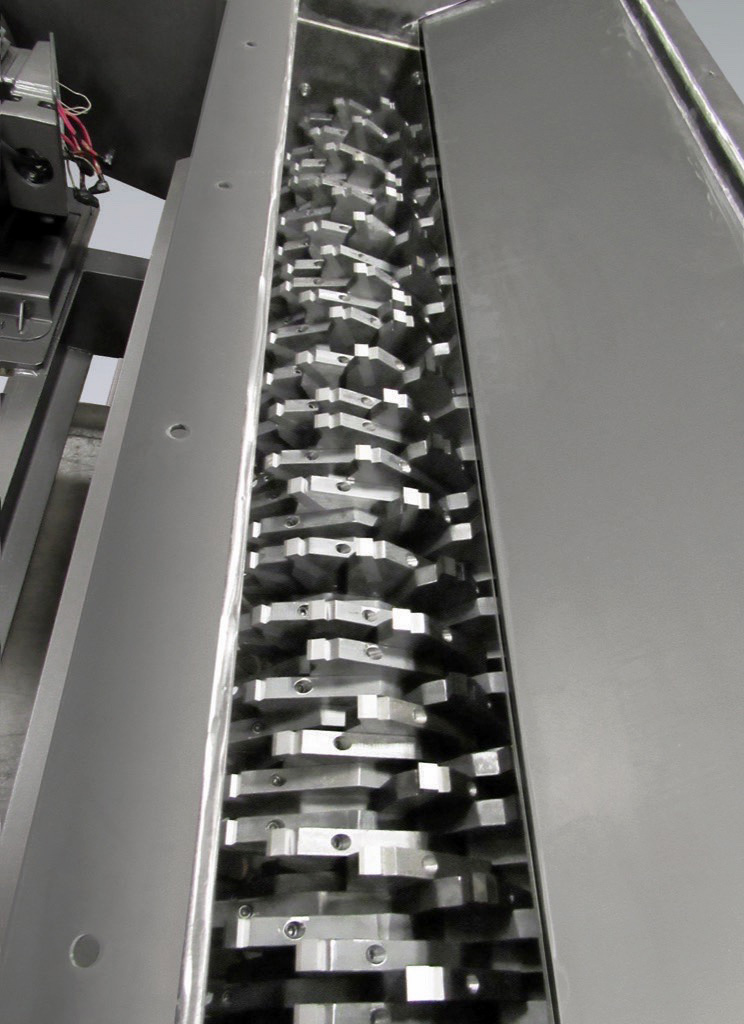

The ultra-heavy-duty unit features a progressively stacked array of 72 interconnected, abrasion-resistant cutter tip holders, each of which holds four 25 mm-wide carbide cutter tips that continuously shear oversize materials against twin, stationary bed knives. Operating at speeds set from 30 to 3600 RPM with a 30+ kW motor, the Magnum 72-AR Screen Classifying Cutter can process up to 20.4 m3/h, depending on application, with little or no fines and virtually no heat generation.Bed screen perforations range from 102 mm to 3.2 mm in diameter, allowing the reduction of materials into uniform particles in sizes down to 6 mesh. Measuring 1830 x 572 mm, the infeed throat accommodates a variety of large, semi-hard, fibrous or friable materials to be recycled or otherwise reduced in size for processing.

Material is fed through the top of the intake chute, which is double-baffled to prevent flash back and dusting, or directly into the front of the cutter through a hinged door. An independently powered, variable speed pinch roller is offered for horizontal feeding of material. Discharge is via gravity, pneumatic collection or independently powered belt or screw conveyor.The cutter tips, which are secured with one retaining socket-head screw for rapid replacement, are supplied as standard in tungsten carbide and available in various grades of tool steel and hardened stainless steel.The unit is offered in lengths down to 610 mm and configured with multiple V-belt drives as standard, or optional direct-coupled gear-reduced drives.All SCC Screen Classifying Cutter models are offered in carbon steel, abrasion-resistant steel and stainless steel. ■