Typically requiring just one re-tensioning during its lifespan, the extremely low maintenance requirements and outstanding cleaning ability help reduce cost of ownership in a wide range of industries, such as mining, coal processing, quarrying, cement production, scrap and other bulk material handling operations.An excellent solution for areas with restricted space, the unique all stainless steel design incorporates a matrix of specially-engineered carbide tips and is tensioned lightly to prevent damage to the belt or splices. Despite extremely low contact pressure between belt and cleaner, it has been shown to effectively remove potential carryback material that was not dislodged by a primary cleaner. The carbide cleaning surfaces deliver excellent performance, and the unit’s light touch helps protect against belt wear.The CS2 can be used with any primary cleaner, but was engineered to be paired with the company’s original CleanScrape® Primary Cleaner (CS1). When used together, they form a rugged, low-maintenance system that effectively removes carryback, helping to prevent fugitive material and the associated cleanup. The system represents a revolutionary concept that delivers superior cleaning and up to 4x the service life of conventional designs, with half the maintenance. The combination has been shown to remove as much as 99% of the carryback in most belt cleaning applications. The reduced service requirements and exceptional durability deliver a low life cycle cost, while allowing crews to focus on other tasks.

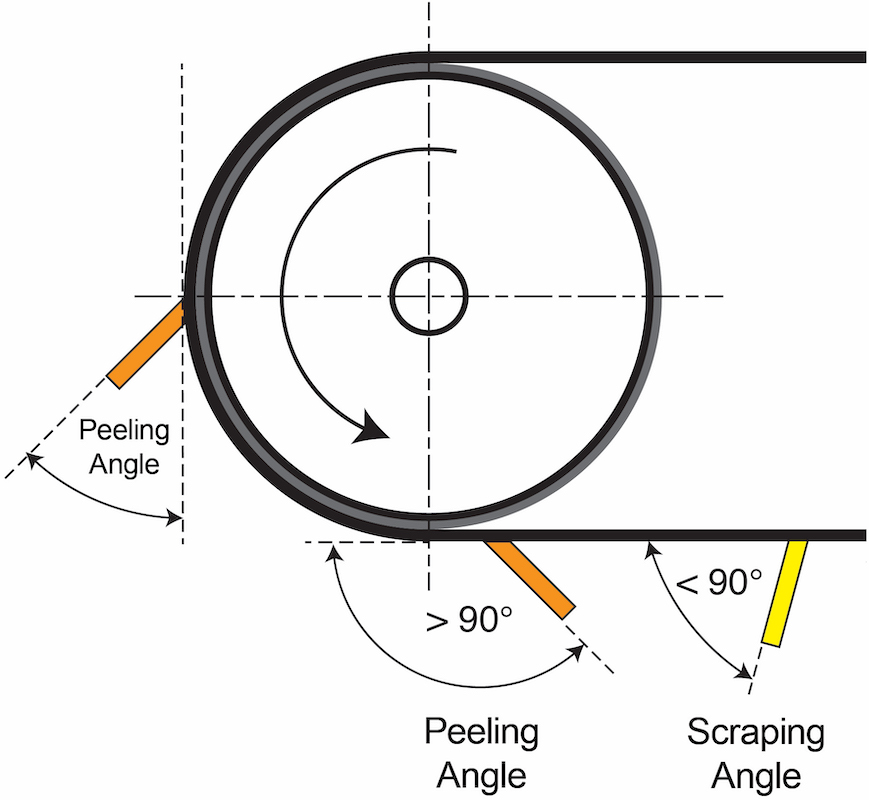

“Many carbide-tipped belt cleaners require high pressure against the belt in order to be effective, and they typically need to be re-tensioned often throughout their service life,” explained Chief Technology Officer Paul Harrison. “Like the CS1, this design is extremely effective with light tension against the belt, which helps avoid the damage to belts and slices that can occur with other carbide-tipped secondary cleaners. And because it only needs tensioning once during its lifespan, the maintenance requirements are very low.”Harrison said that the negative rake angle of the CS2 is also key to the new design. “Some manufacturers use a positive angle of attack at the secondary position, which is greater than 90 degrees,” he continued. “That’s common in a urethane primary cleaner, which is tensioned tightly against the pulley. But using a ‘peeling’ action in a secondary cleaner can damage and prematurely wear the belt cover. It can be catastrophic on “beaver tails” (small sections of belt damage where a section of the top cover has separated from the belt carcass). With a negative rake angle and the ‘scraping’ action it provides, the CleanScrape Secondary Cleaner delivers outstanding performance, while mitigating potential belt damage.”

Intelligent Design

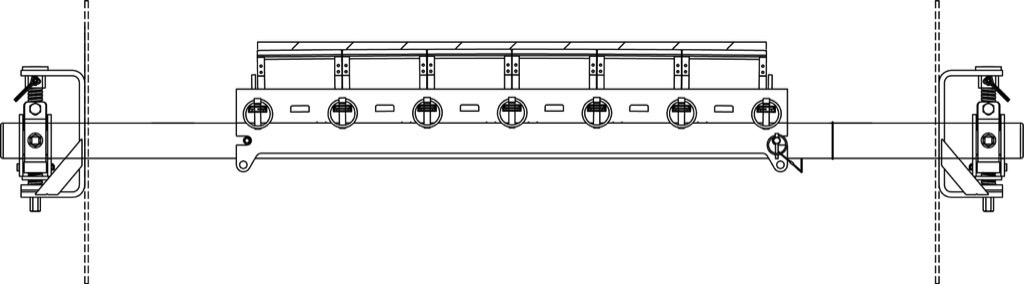

The “free flow” design, with an absolute minimum of exposed surface area, delivers optimum cleaning results while allowing material to pass through the arms and return to the cargo flow. The compact system requires very little free space, and can be easily installed inside or outside of discharge chutes, while the crowned main frame compensates for cupping or wear of the center of the belt.The carbide blade tips have a small corner radius to protect against belt damage, and each one is supported on spring-loaded arms at both ends. The load springs allow independent blade rotation back and forth, as well as up and down. This range of motion provides equal load pressure across each blade, bypassing obstructions and conforming to ever-changing belt undulations. The unique design holds the blade in an effective cleaning position but allows the blades to retreat into a safe position for reversing belts or rollback.

“This new design is engineered to withstand high production demands in which maintenance and conveyor stoppages must be minimized,” said Harrison. “The combination of CleanScrape primary and secondary cleaners offers these customers a matched set of components that require half the maintenance of conventional designs, helping to reduce service costs and production downtime.”The CleanScrape Secondary Cleaner is suitable for conveyor speeds up to 5 m/s (900 fpm) on belts with vulcanized splices, and up to 3 m/s (600 fpm) on belts with mechanical splices. Supplied with a stainless steel tensioner, it can withstand temperatures as high as 260°C (500°F). Available for any size belt in full belt widths or 150 mm (6 in) less than belt width, the unit can be specified with Martin’s unique Safe-To-Service technology -giving maintenance personnel the ability to work on the assembly safely from outside the chute wall or conveyor structure -without breaking the safety plane.

“Some plants require a confined space permit if workers are going to reach through the outer edge of the chute work,” Harrison added. “With all adjustments being made from the operator side, there is no need to enter a confined space.”Engineered to disengage from the tensioner, Safe-To-Service designs allow the cleaner to be pulled out far enough to take out a quick-release pin and remove the assembly. Once the new unit is installed, it’s simply pushed back into position and the tensioner re-engaged. The one-pin procedure makes replacement an easy, no-tool operation performed from the outside of the chute.Both of the CleanScrape Cleaner designs meet all regulatory requirements for use in underground mining. Pre-assembled primary and secondary belt cleaners for standard belt widths are supplied ready for installation. The primary cleaner can also be supplied in coiled lengths of 12.4 meters (40.68 feet), allowing users to cut to length as needed and not have to stock multiple belt width sizes.“The CleanScrape Cleaner System represents an entirely new dimension in belt cleaning,” Harrison concluded. “We’re so confident in the performance of these products that we provide a money-back satisfaction guarantee.” ■